Method for preparing calibrated biodegradable microspheres

A kind of microsphere, biological technology, applied in the field of pharmaceutical industry, to achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0121] General procedure for preparing microspheres from single emulsions:

[0122] This method can be used to prepare biodegradable polymer microspheres, which are especially useful for the delivery of lipophilic active ingredients.

[0123] The active ingredient to be encapsulated is dispersed or dissolved in an organic phase consisting of PLGA dissolved in vinyl acetate.

[0124] Then, the organic phase is emulsified in an aqueous phase containing water and a hydrophilic surfactant such as PVA in an amount of 0.1-10%, preferably 1-4%, and a viscosity agent such as poly Ethylene glycol or poloxamer, the content is 10-50%.

[0125] To optimize shear efficiency, the viscosity ratio of the two phases can be adjusted. Preferably the viscosity ratio of the organic phase to the aqueous phase is 0.1-10, more precisely 3-8.

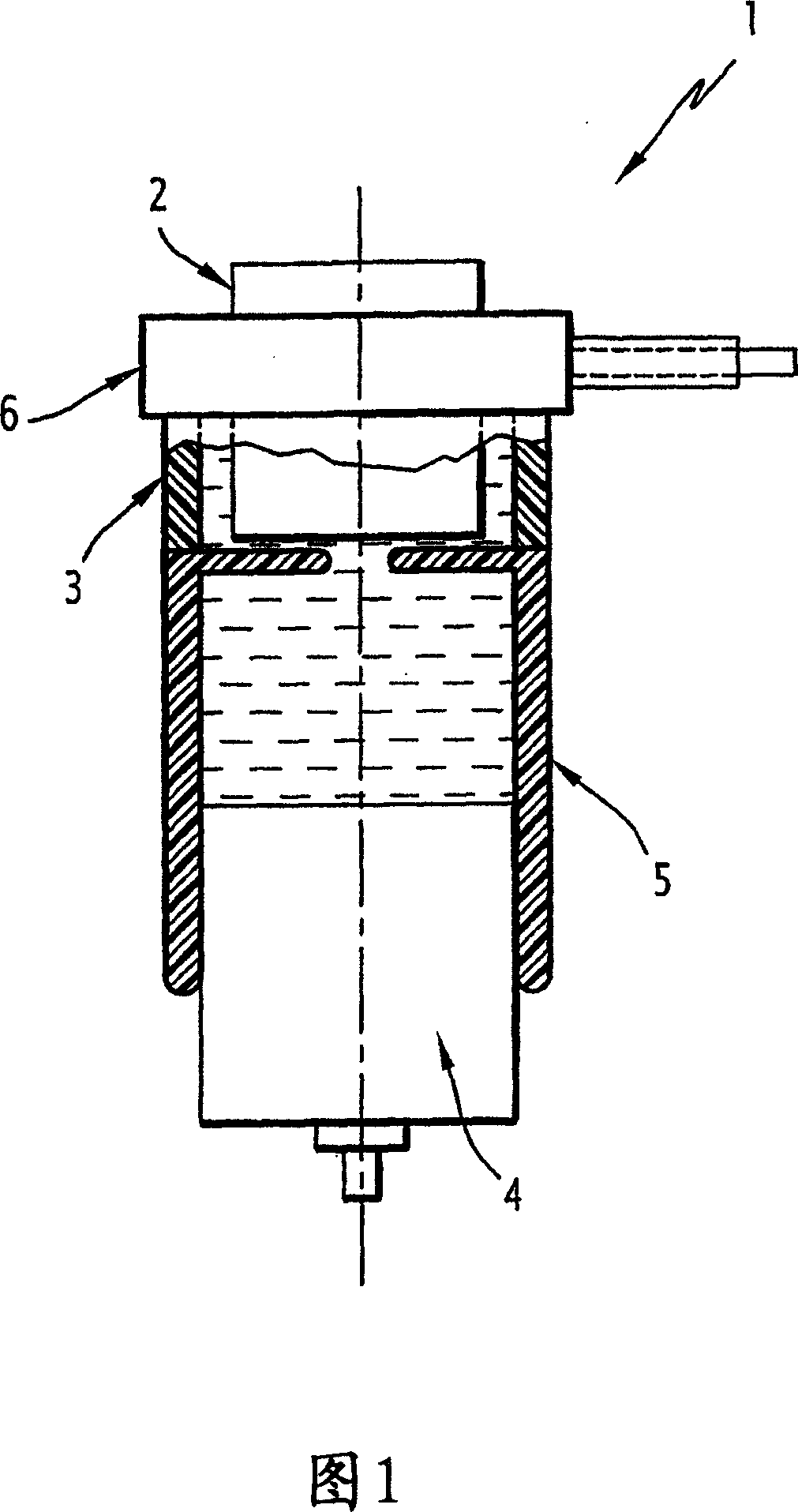

[0126] The so-called "coarse" emulsions thus obtained are then subjected to laminar shear. This step is preferably carried out in a Couette apparatus, as...

Embodiment approach 2

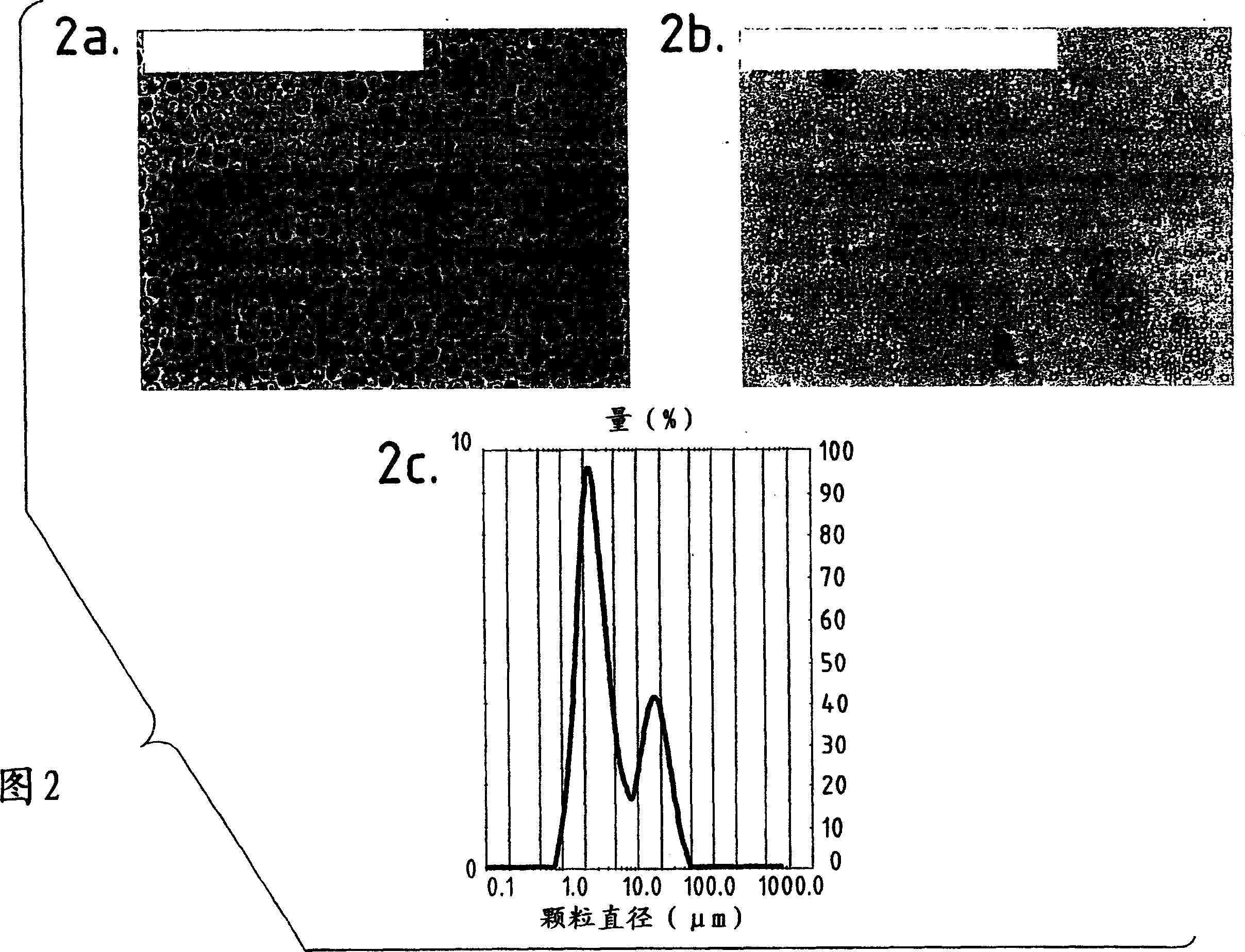

[0135] Preparation of 2.5 µm microspheres from a single emulsion:

[0136] In a flask, the continuous aqueous phase was prepared by dissolving 0.9 g of PVA in 14.14 g of demineralized water (3%) at vinyl acetate saturation under magnetic stirring at 70°C. After cooling, 15 g of PEG 400 was added thereto. The aqueous phase therefore contained 3% PVA, 50% PEG 400 and was saturated with vinyl acetate.

[0137] The organic phase was prepared in a sealed bottle by dissolving 2.6 g of PLGA 75 / 25 in 17.39 g of a water-saturated vinyl acetate solution (3%) under magnetic stirring. The organic phase thus contained 13% PLGA dissolved in water-saturated vinyl acetate.

[0138] All these organic phases were then emulsified in 20 g of the above aqueous phase by manual stirring using a spatula. The emulsion contains 50% by mass of the dispersed organic phase.

[0139] The premix thus obtained was placed in a Couette apparatus and sheared at 400 rpm in a gap of 100 μm with a piston upf...

Embodiment approach 3

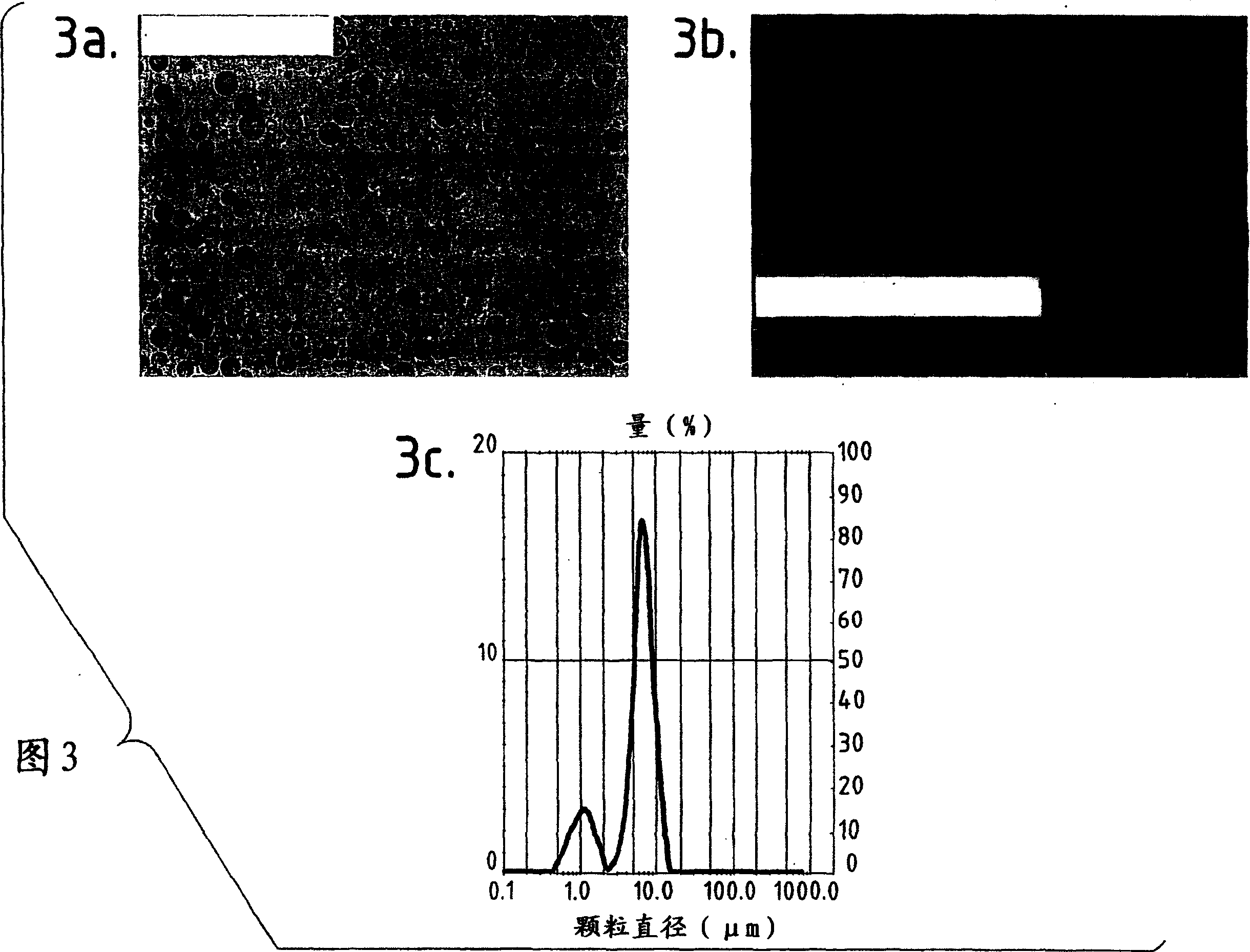

[0143] Preparation of 6.5 µm microspheres from a single emulsion:

[0144] In a flask, the continuous aqueous phase was prepared by dissolving 1.2 g of PVA in 35.25 g of demineralized water (3%) at vinyl acetate saturation under magnetic stirring at 70°C. After cooling, 4.02 g of PEG 2000 was added thereto. The aqueous phase therefore contained 3% PVA, 10% PEG 2000 and was saturated with vinyl acetate.

[0145] The organic phase was prepared in a sealed flask by dissolving 2.67 g of PLGA 75 / 25 in 17.89 g of a water-saturated vinyl acetate solution (3%) under magnetic stirring. The organic phase thus contained 13% PLGA dissolved in water-saturated vinyl acetate.

[0146] All these organic phases were then emulsified in 20 g of the above aqueous phase by manual stirring using a spatula. The emulsion contains 50% by mass of the dispersed organic phase.

[0147] The premix thus obtained was placed in a Couette apparatus and sheared at 300 rpm in a gap of 100 μm with a piston...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com