Lateral flow format, materials and methods

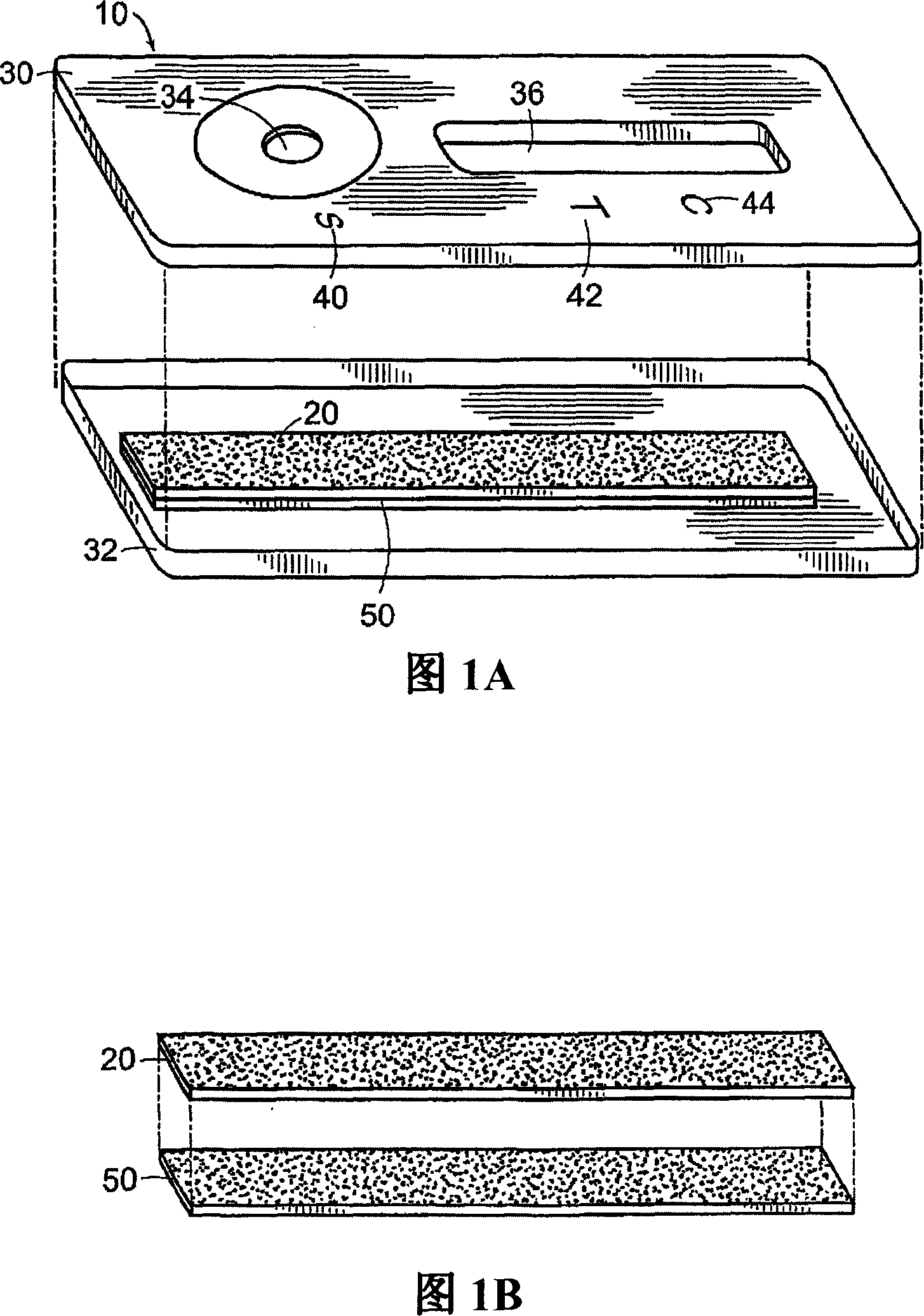

A technology for test strips and markings, applied in the field of lateral flow formats, materials and methods, can solve problems such as difficult manufacturing, flow problems encountered in lateral flow testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

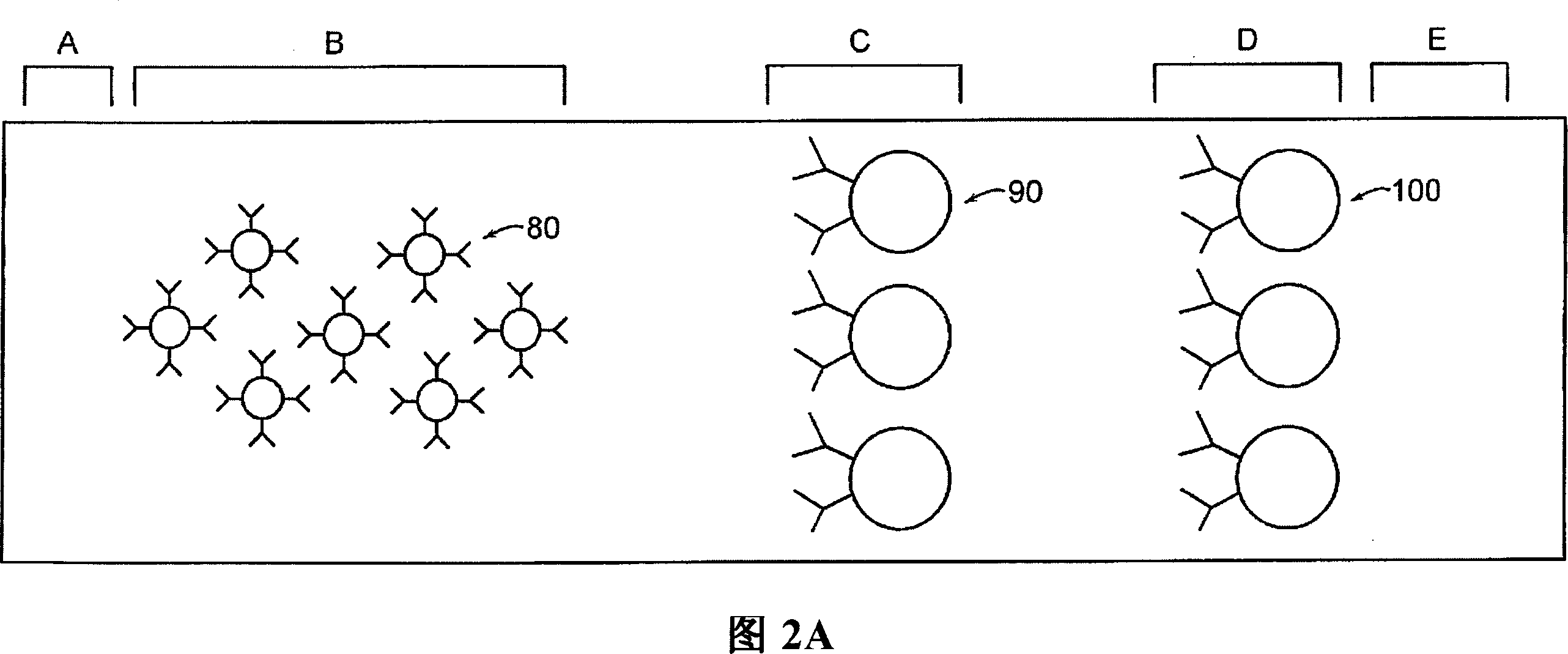

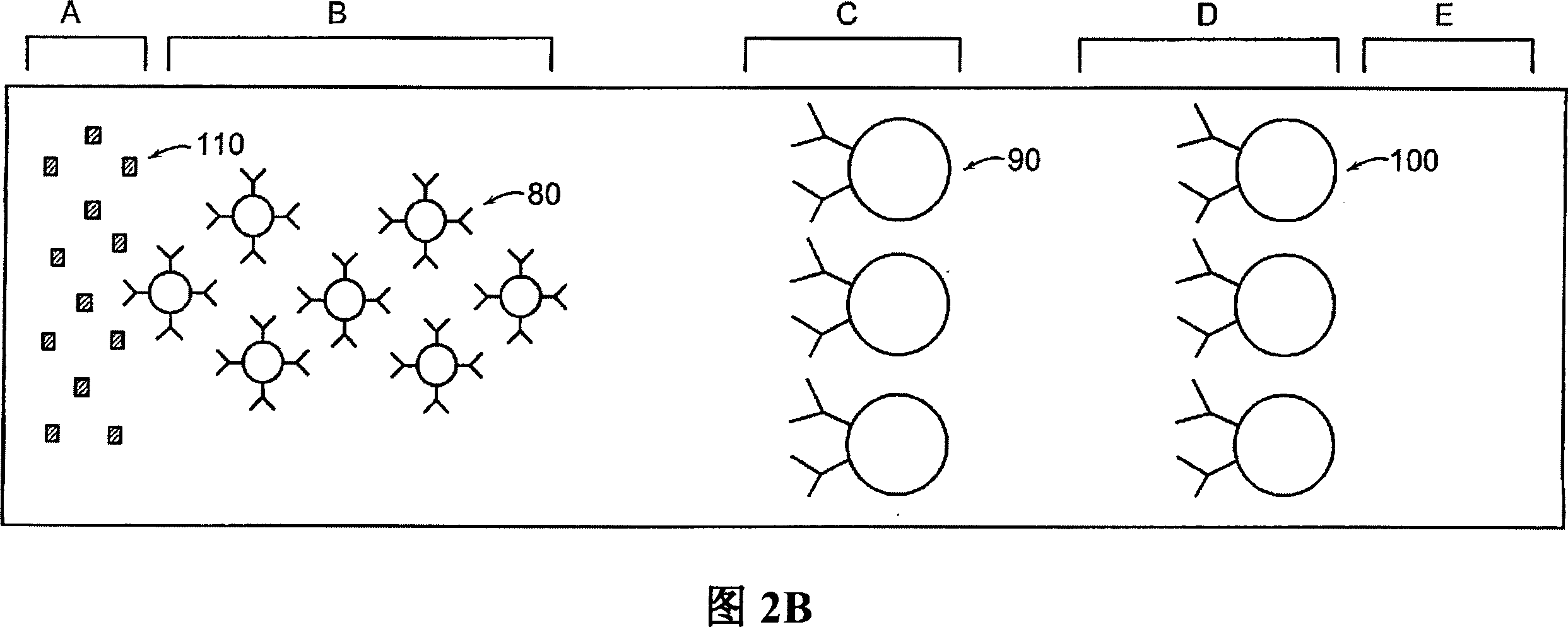

Method used

Image

Examples

preparation example Construction

[0397] In yet another aspect, the present invention provides a method of preparing a test strip for detecting the possible presence of an analyte in a liquid sample applied to the test strip, the test strip comprising a dry porous medium, the dry porous medium comprising a single hydrophilic matrix comprising a monolithic hydrophilic matrix, wherein the method comprises:

[0398] a. providing a monolithic hydrophilic substrate, wherein the monolithic hydrophilic substrate comprises a fiber network;

[0399] b. Create a conjugate release zone on the monolithic hydrophilic matrix by:

[0400] i. A labeled binding agent is provided, wherein the labeled binding agent comprises:

[0401] - a mark;

[0402] - a solid substrate comprising a carrier bead, wherein when the carrier bead and substrate are wetted

[0403] the carrier beads are mobile within the matrix; and

[0404] - a ligand that specifically binds to the analyte to form a first complex comprising the labeled binding...

example 1

[0717] Example 1: FUSION 5 TM Absorbency Comparison with Other Materials

[0718] Fusion 5 TM (Whatman pic) can be used as a hydrophilic matrix in a preferred embodiment of the present invention, FUSION 5 TM The absorbency was compared with that of three other commonly used materials (CF3, CF4 and CF5) in the industry standard. CF3, CF4 and CF5 are cellulose absorbents commonly used in industrial lateral flow analysis and are well known in the art.

[0719] Program

[0720] 10 ml of deionized water was placed in a Petri dish. Weigh 5cm 2 absorbent tablet, then placed in water and left for 10 seconds. Remove absorbent and reweigh. Subtract the dry weight from the wet weight to get 5cm 2 water absorption of the sheet. Five such tests were carried out for each absorbent.

[0721] result:

[0722] The results of this experiment are shown in the bar graph of FIG. 3 . The water absorption per square centimeter of the other three materials ranges from about 30 mg / cm 2...

example 2

[0726] Example 2: FUSION 5 TMCompared with the imbibition rate of nitrocellulose membrane

[0727] Fusion 5 TM (Whatman pic) can be used as a hydrophilic matrix in a preferred embodiment of the present invention, FUSION 5 TM The imbibition rate was compared with that of three nitrocellulose membranes (RP, FP and SP). Among these nitrocellulose membranes, the RP membrane has the largest average pore size, while the SP membrane has the smallest average pore size.

[0728] Program:

[0729] Place 10 ml of deionized water in a Petri dish. These wicking materials were cut to a length of 5 cm and marks were drawn with a soft pencil 0.5 mm from the top and bottom edges. The wicking material is suspended vertically from a jig stand and lowered into the water until the water reaches the 0.5 mm mark. Record the time for water imbibition to reach this top mark. This test was repeated 3 times for each material.

[0730] result:

[0731] The results of this experiment are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com