Vibration sesor

A vibration sensor and vibrating plate technology, which is applied to electrostatic transducer microphones, instruments, electret electrostatic transducers, etc., can solve problems such as poor assembly, large product performance deviation, and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

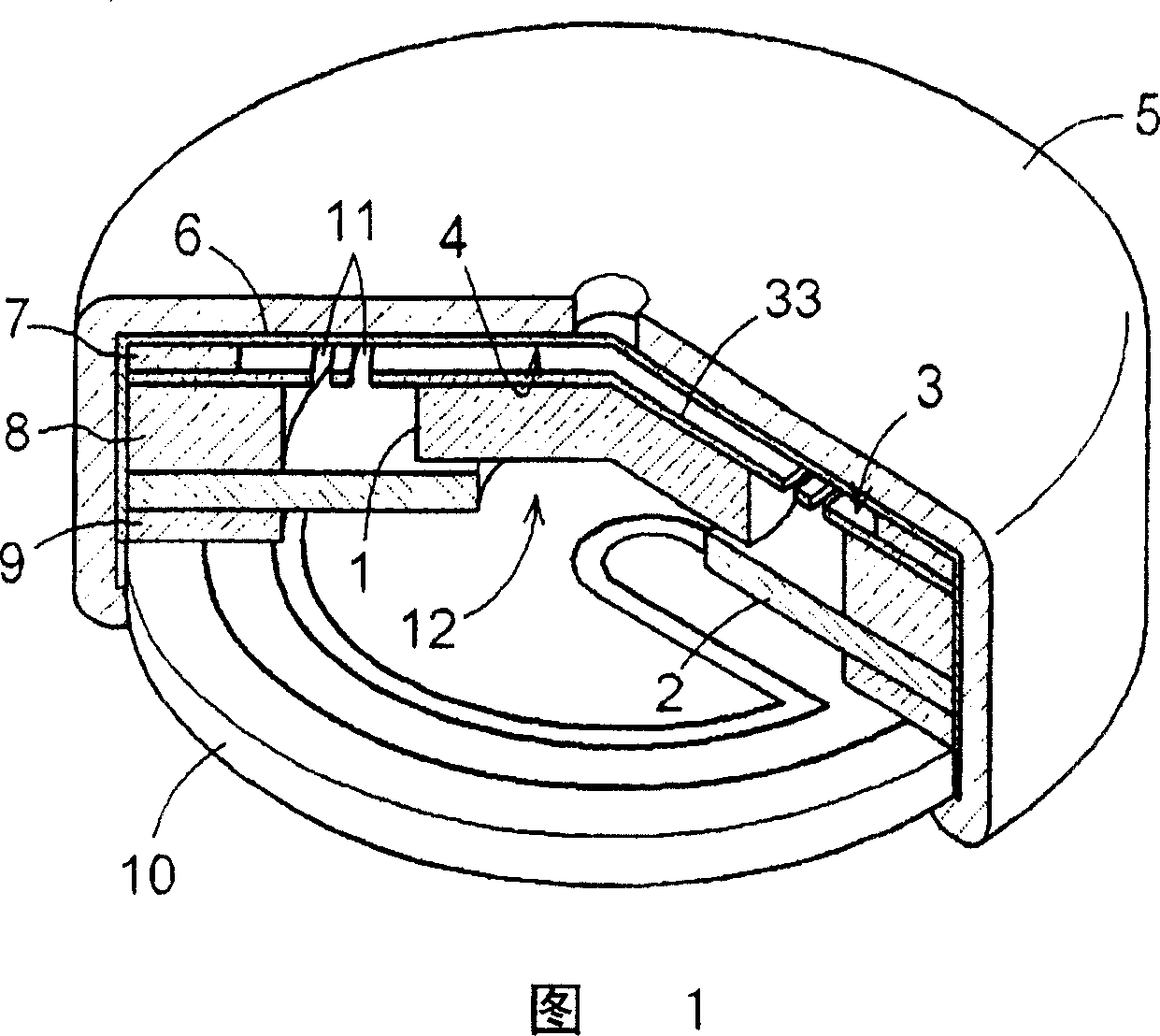

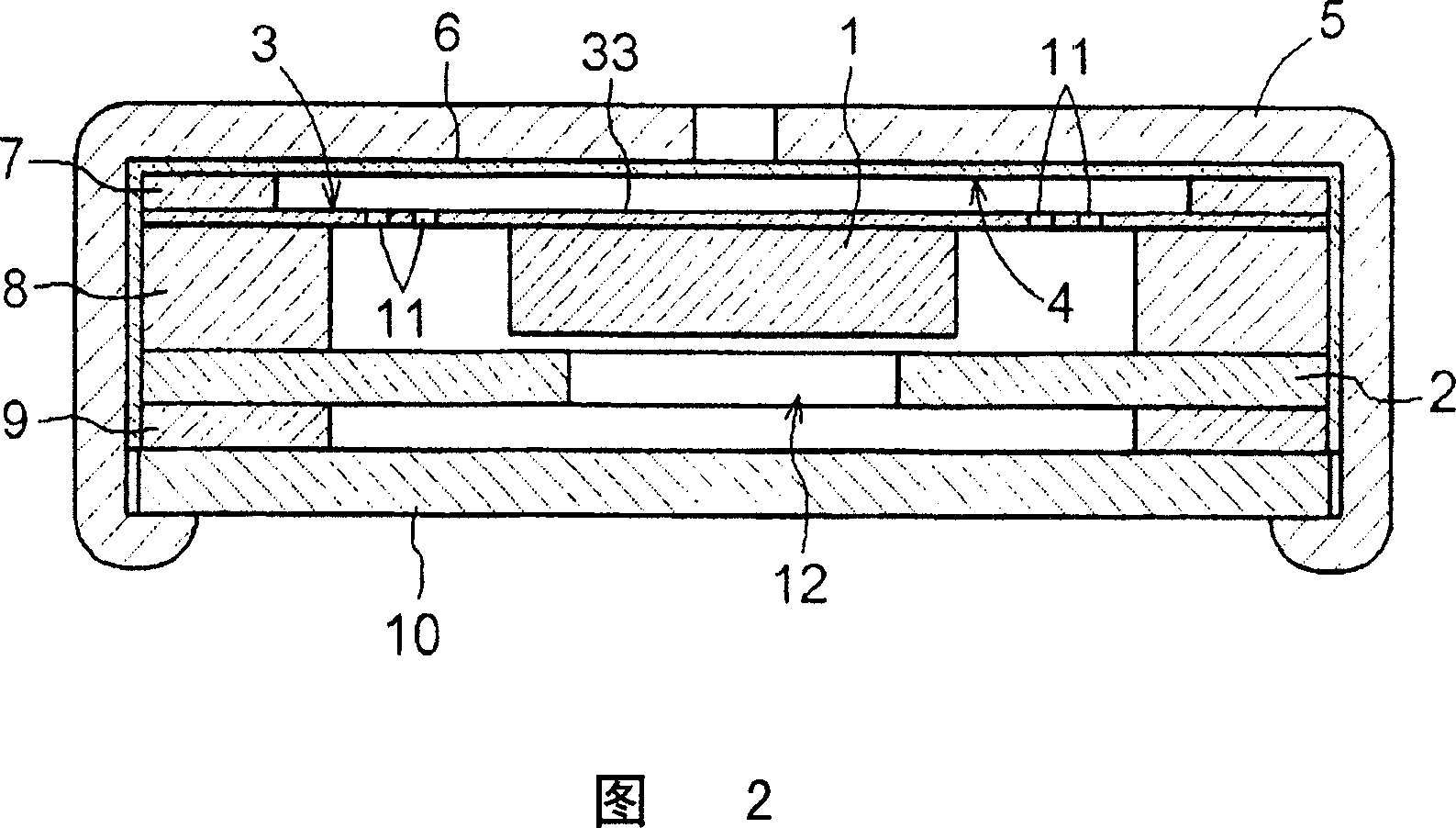

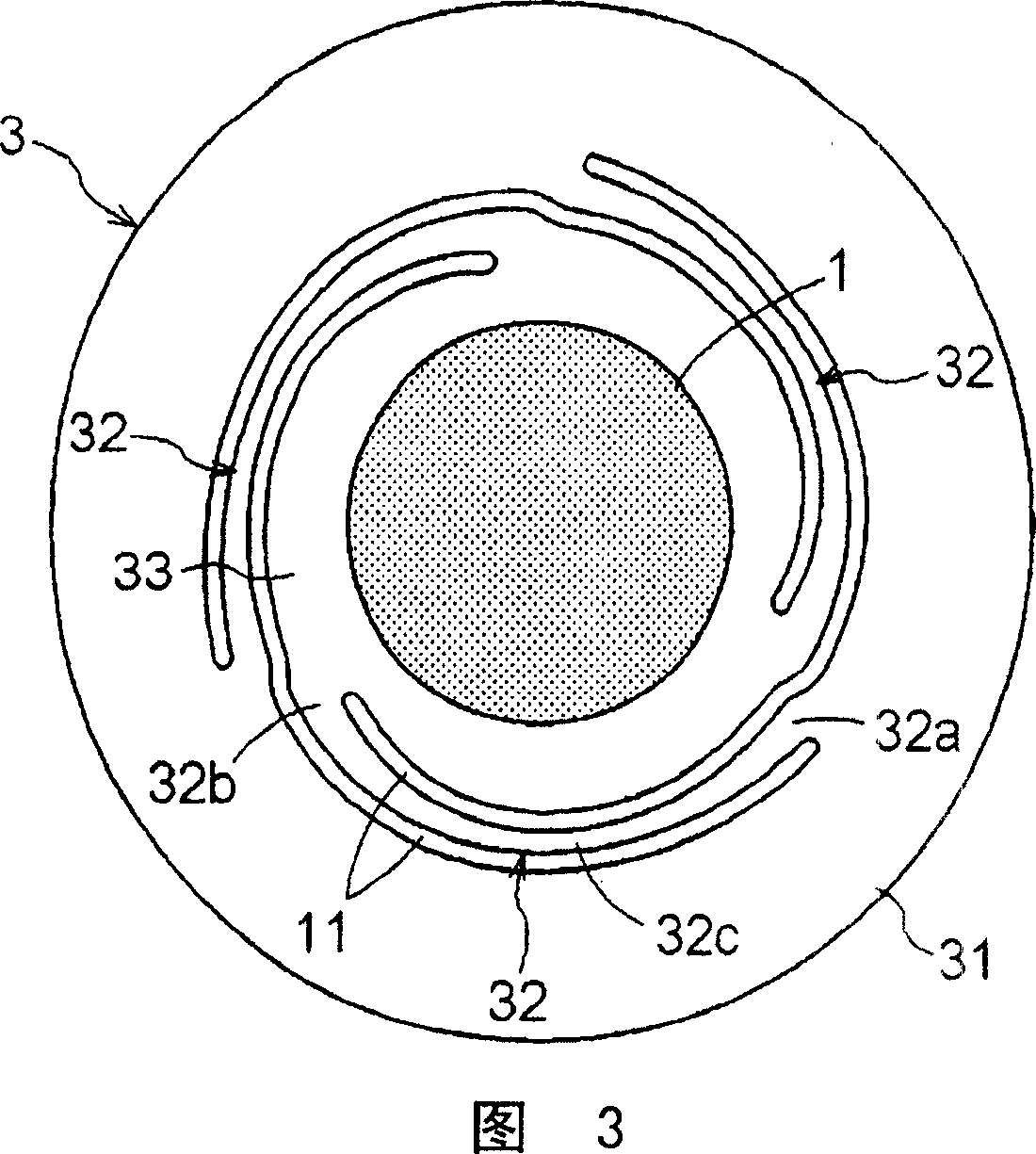

[0032] Hereinafter, embodiments of the present invention will be described based on the drawings. FIG. 1 is a perspective view showing an example of a vibration sensor of the present invention. Fig. 2 is a cross-sectional view of the vibration sensor shown in Fig. 1 . As shown in Fig. 1 and Fig. 2, the vibration sensor of one embodiment of the present invention comprises: fixed electrode 4, is formed with electret layer 6 on the inner surface of casing 5; The surface on which it is placed functions as a vibrating electrode, and the weight portion 1 is provided on the surface opposite to the vibrating electrode. The weight part 1 is displaced in a direction perpendicular to the surface of the vibration plate 3 , and outputs a vibration detection signal based on a change in capacitance between the fixed electrode 4 and the vibration plate 3 . Furthermore, it is comprised so that it may have the restriction plate (restriction member) 2 which contacts the weight part 1, and rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com