Rotational flow microporous filter

A microporous filter and swirling flow technology, applied in filtration separation, filtration circuits, chemical instruments and methods, etc., to achieve the effect of prolonging the cleaning cycle, solving serious membrane pollution, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

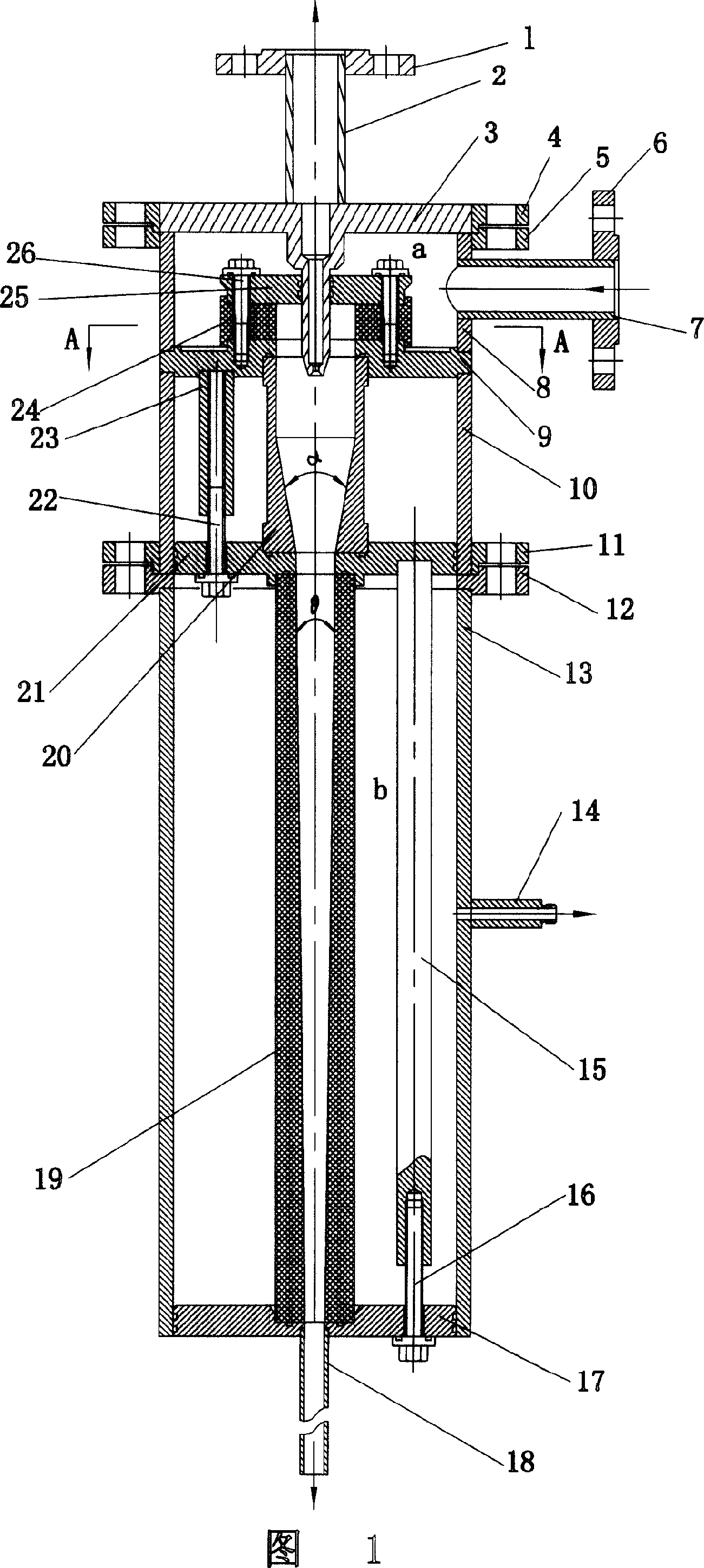

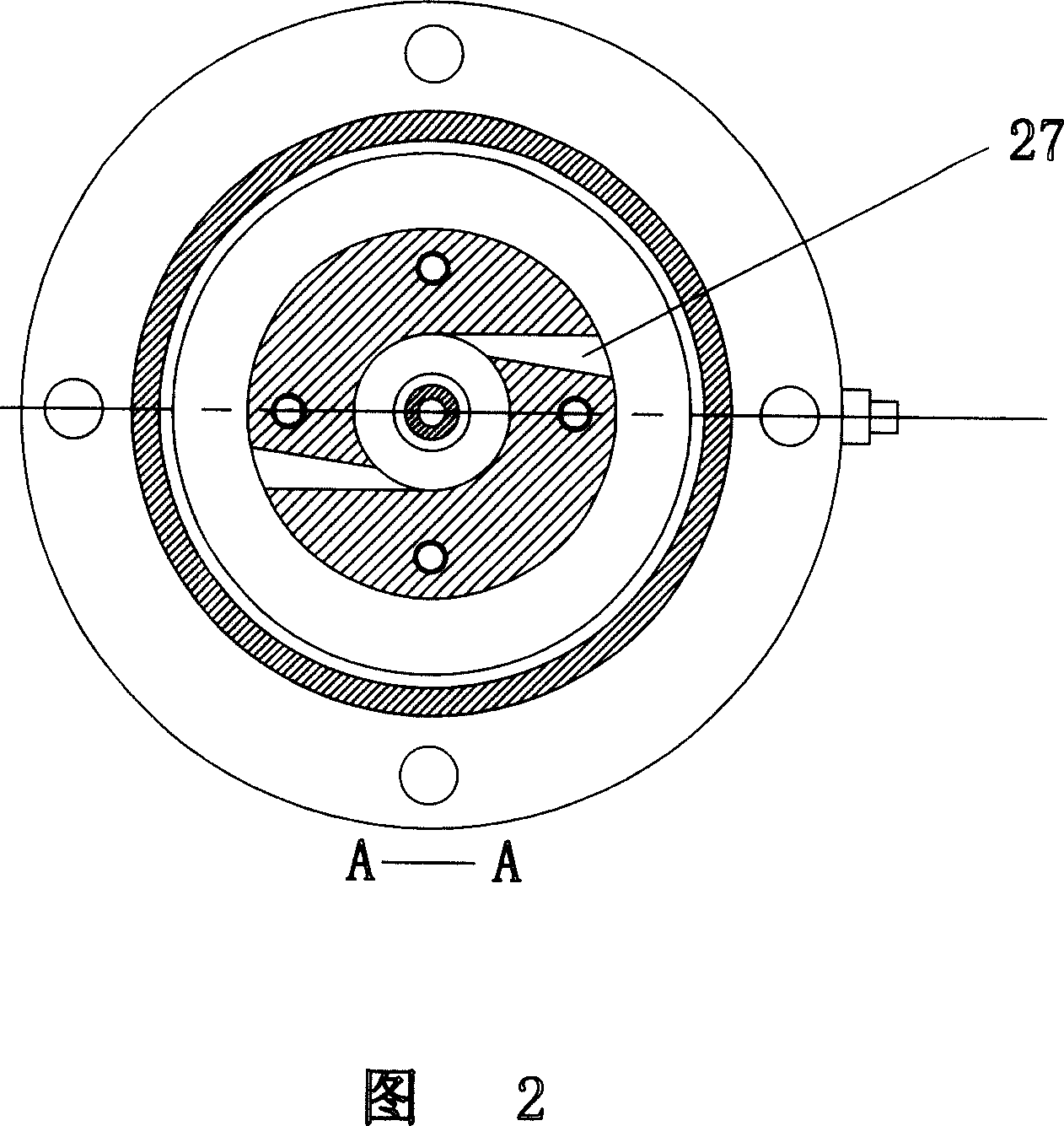

[0010] As shown in Figure 1, the various rotating flow microporous filters include an assembly I consisting of an overflow outlet pipe flange 1, an overflow outlet pipe 2, an overflow pipe 3, and an overflow pipe upper flange 4. Lower flange 5, raw water inlet flange 6, two parallel raw water inlet pipes 7, raw water chamber sleeve 8, upper partition 9, swirl tube sleeve 10, middle upper flange 11, middle partition connecting nut 23 Component II, component III consisting of middle lower end flange 12, filter chamber sleeve 13, filtered water outlet pipe 14, filtered water chamber connecting long nut 15, component III composed of lower partition 17, bottom outflow pipe 18 IV. In addition, it also includes a microporous tube 19 with a small cone section with micro holes, a swirl tube 20 , a middle partition 21 , an inlet backing plate 24 of the swirl chamber and an upper cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com