Scalable steel pipe concrete support

A technology of steel tube concrete and concrete, which is applied in pillars/brackets, earth square drilling, mining equipment, etc. It can solve the problems of U-shaped steel bracket bearing capacity reduction, affecting mine production and safety, uneven pressure distribution, etc., and achieve reasonable force , high support efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

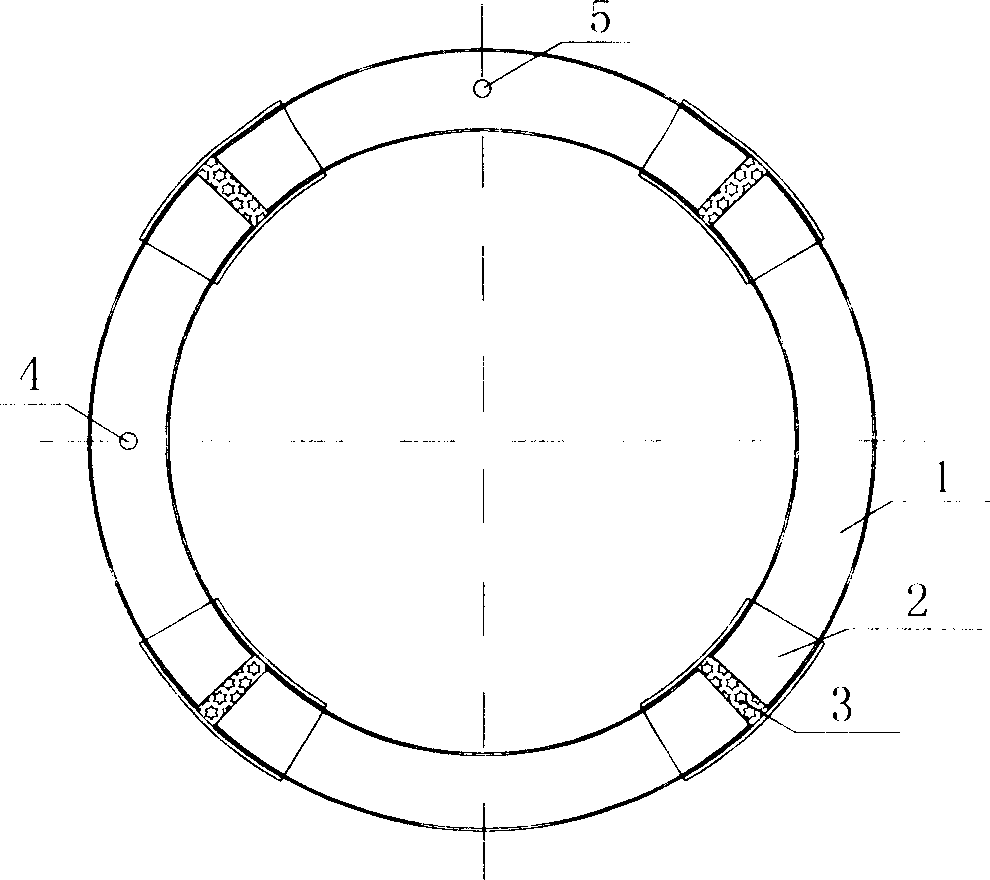

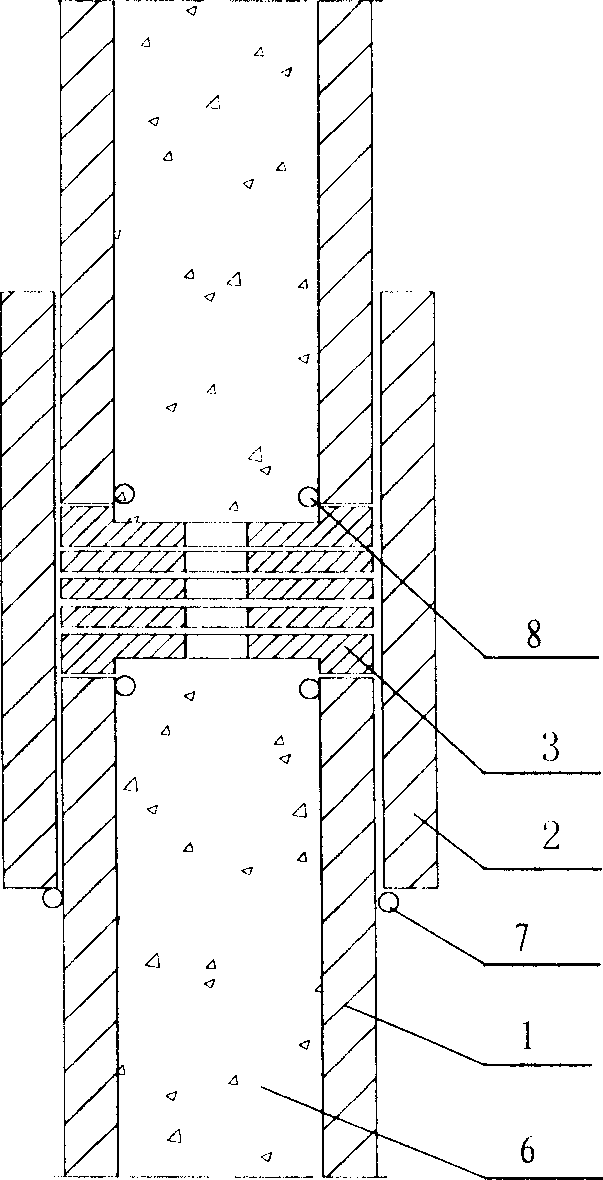

[0025] A preferred embodiment of the present invention is that it includes a multi-section hollow tube body, the multi-section hollow tube body is connected to each other to form a ring structure, and the interior of the hollow tube body is filled with a coagulant.

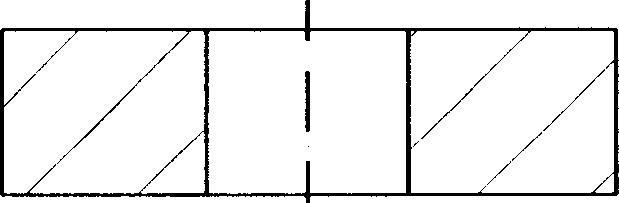

[0026] Such as figure 1 As shown, the multi-section hollow pipe body is a steel pipe 1 with the same arc shape, the multi-section steel pipes 1 are connected to each other to form a circular structure, and the inside of the steel pipe is filled with concrete.

[0027] The hollow tube body can also be made of other rigid materials. The cross section of the hollow tube body is preferably circular, and can also be in other shapes as required, such as ellipse, square, etc.

[0028] The multi-section hollow pipes are preferably connected to each other to form a closed ring structure. The arcs of the multi-section hollow pipes are the same, and they can also be connected into other ring structures, such as ellipse, obla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com