Lithium secondary batteries with charge-cutoff voltages over 4.35

A lithium secondary battery, battery technology, applied in the direction of secondary battery, secondary battery repair/maintenance, lithium storage battery, etc., can solve the problems of positive electrode surface deterioration, side reaction, lithium dendrite growth, etc., to improve the average discharge voltage , the effect of preventing security degradation and increasing usable capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0066] [Example 1-5. Manufacture of battery with charge cut-off voltage exceeding 4.35V]

Embodiment 1

[0067] Embodiment 1. The lithium secondary battery (1) that the charging cut-off voltage is 4.35V

[0068] (production of positive electrode)

[0069] Mix 95wt% LiCoO with a particle size of 10μm 2 , 2.5wt% conductive agent and 2.5wt% binder to form a slurry. The slurry was uniformly applied on both surfaces of an aluminum foil with a thickness of 15 μm and then calendered to obtain an active material weight of 19.44 mg / cm 2 positive pole. The final positive electrode has a thickness of 128 μm.

[0070] (manufacture of negative electrode)

[0071] 4.0 wt% binder and 0.7 wt% conductive agent were added to 95.3 wt% graphite and mixed to form a slurry. The slurry was uniformly applied on both surfaces of a copper foil with a thickness of 10 μm, followed by calendering to obtain an active material weight of 9.56 mg / cm 2 the negative pole. The weight ratio (A / C) of the positive electrode active material to the negative electrode active material per unit area of the respect...

Embodiment 2

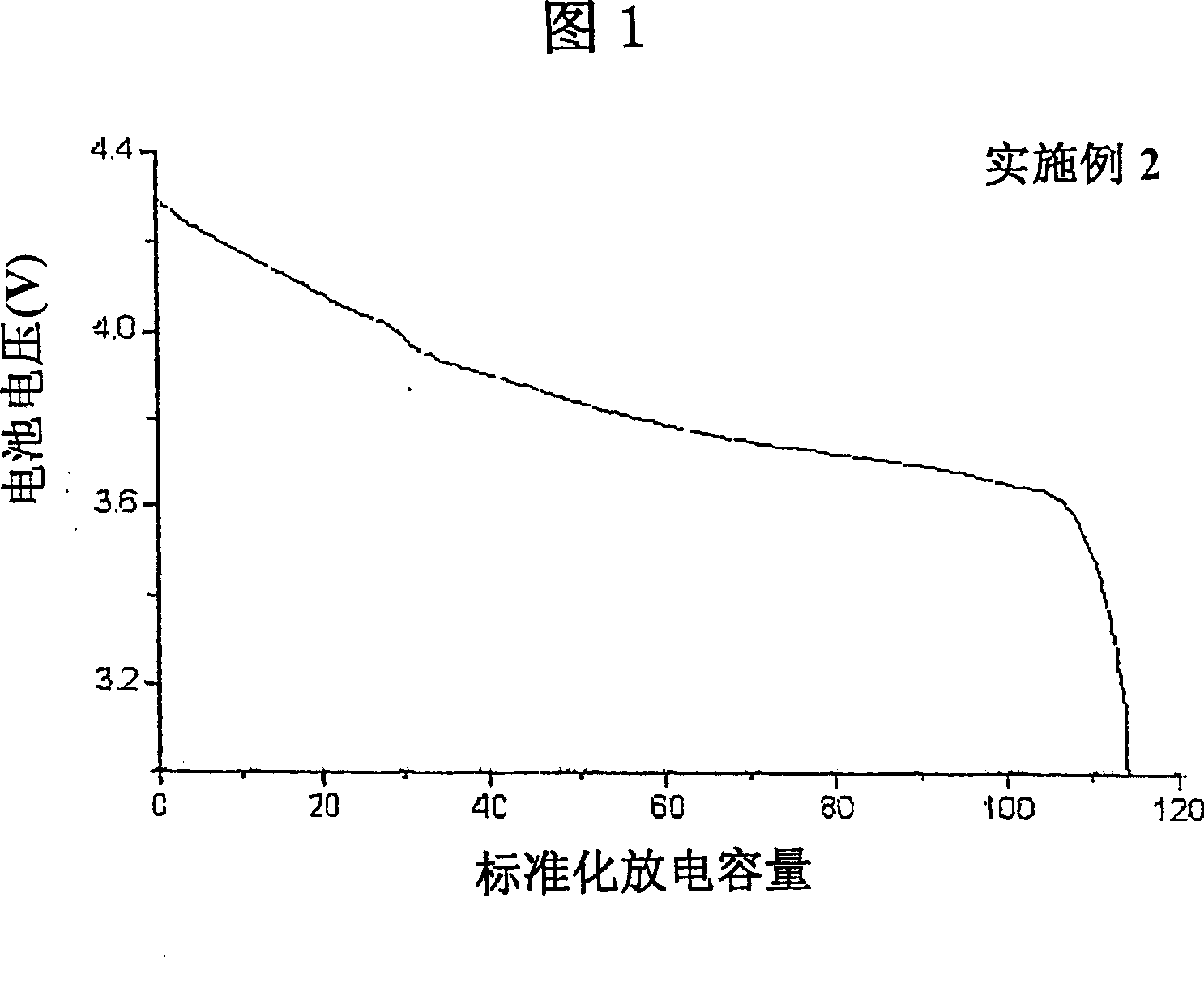

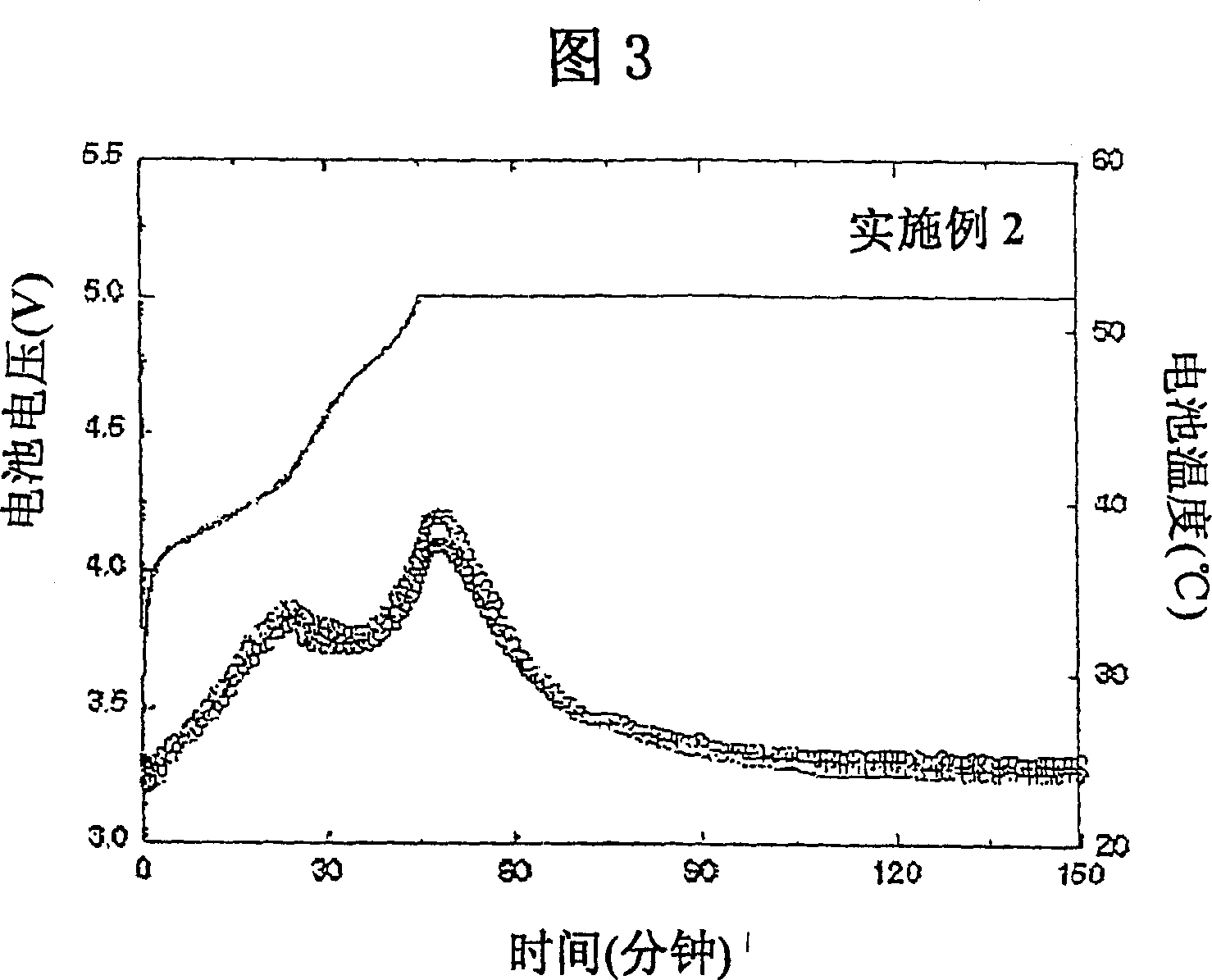

[0076] Embodiment 2. The lithium secondary battery (2) that the charging cut-off voltage is 4.35V

[0077] Repeat Example 1 to obtain a lithium secondary battery, except that the active material weight is 22 mg / cm 2 The weight of positive electrode (C) and active material is 11 mg / cm 2 The weight ratio (A / C) of the negative electrode active material to the positive electrode active material per unit area of each electrode is adjusted to 0.50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com