Method for manufacturing industrialized production shop for bagged edible fungus suspension cultivation

A production workshop, factory-like technology, applied in the fields of botanical equipment and methods, cultivation, application, etc., can solve the problems of large floor space, low output, and precipitation of investment funds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

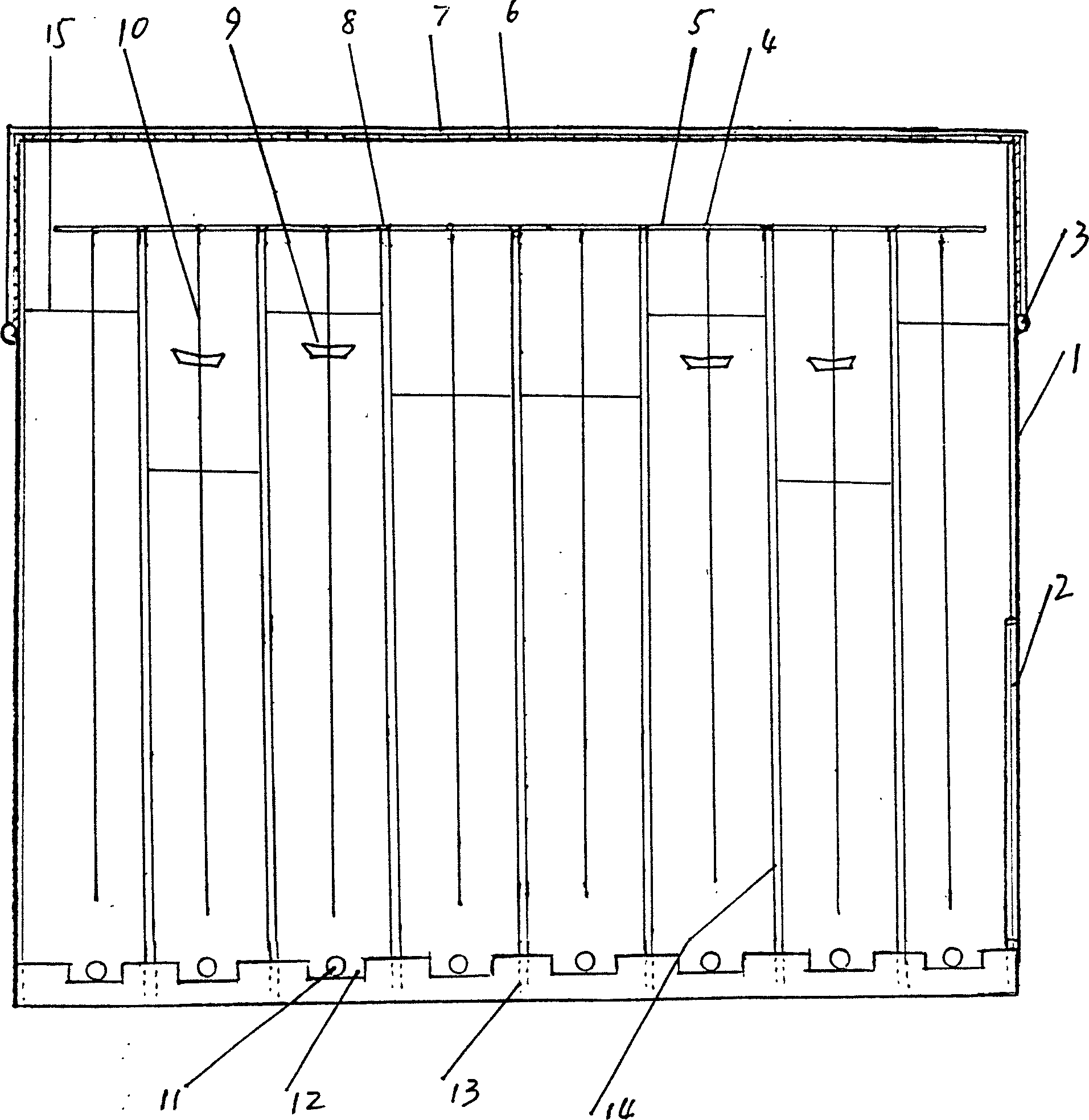

[0005] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0006] Provided by accompanying drawing, the present invention is at first mixed with cement and sand and adds water to make cement concrete floor 13 (can get final product with conventional concrete technology, as cement: sand=1: 2 mixes water and mixes and becomes slurry after drying and solidifying. ), while making the floor, reserve a groove 12 and a stake insertion hole on the ground plane, place a nozzle 11 with holes for temperature and humidity regulation in the groove 12, and insert the stake on the floor Vertical pile 14 is installed in the hole, the top of the pile is equipped with a horizontal pile rod 5 for hanging batch rope, and the horizontal pile rod for hanging batch rope is equipped with hanging fungus bag batch rope 10, and the surrounding area of the cement concrete floor is installed The wall 1 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com