Portable electric plane

A portable, electric planing technology, applied in the direction of manual planing, etc., can solve the problems of inconvenience, labor intensity and safety hazards, and achieve the effect of convenient operation, increased operation safety and efficient planing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

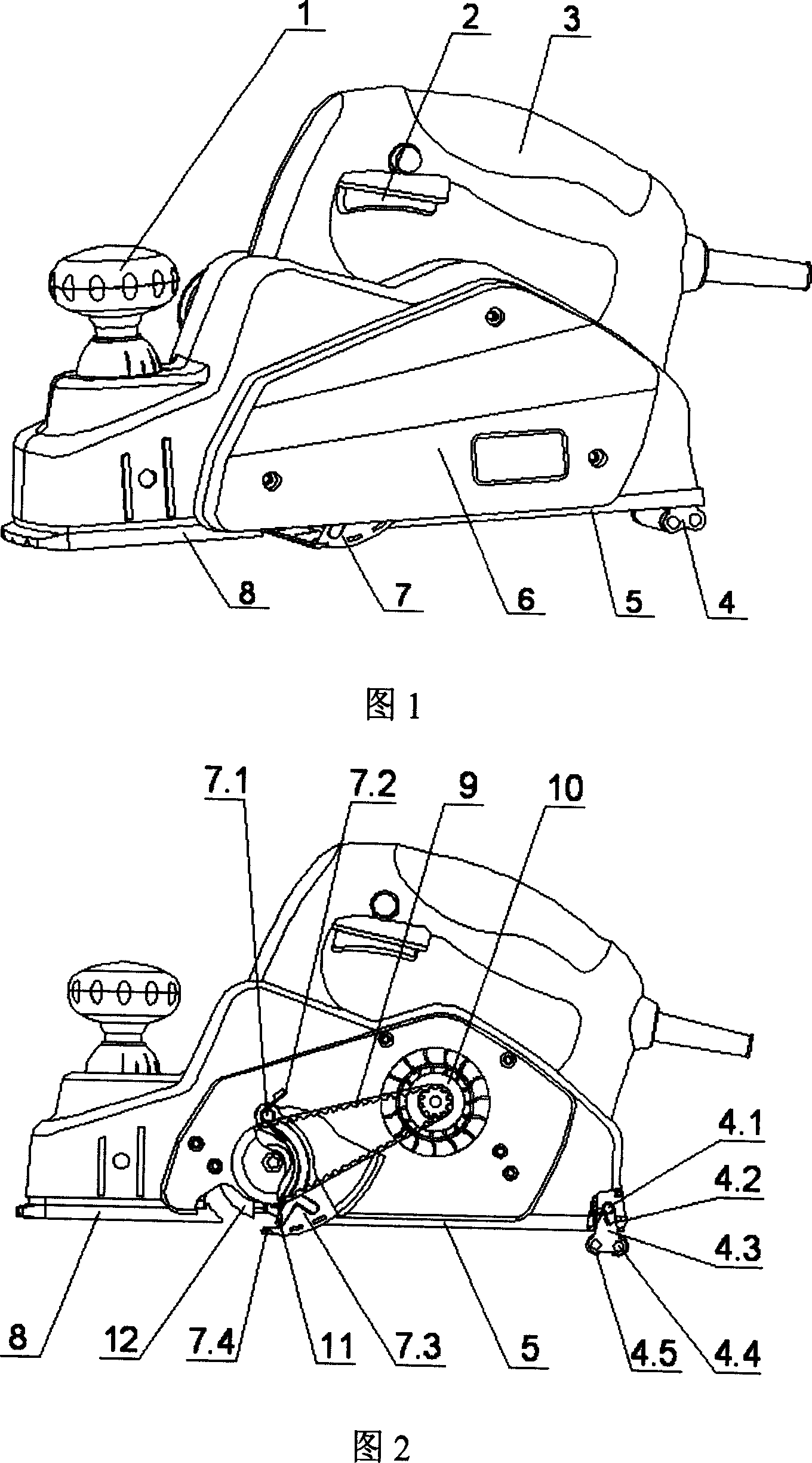

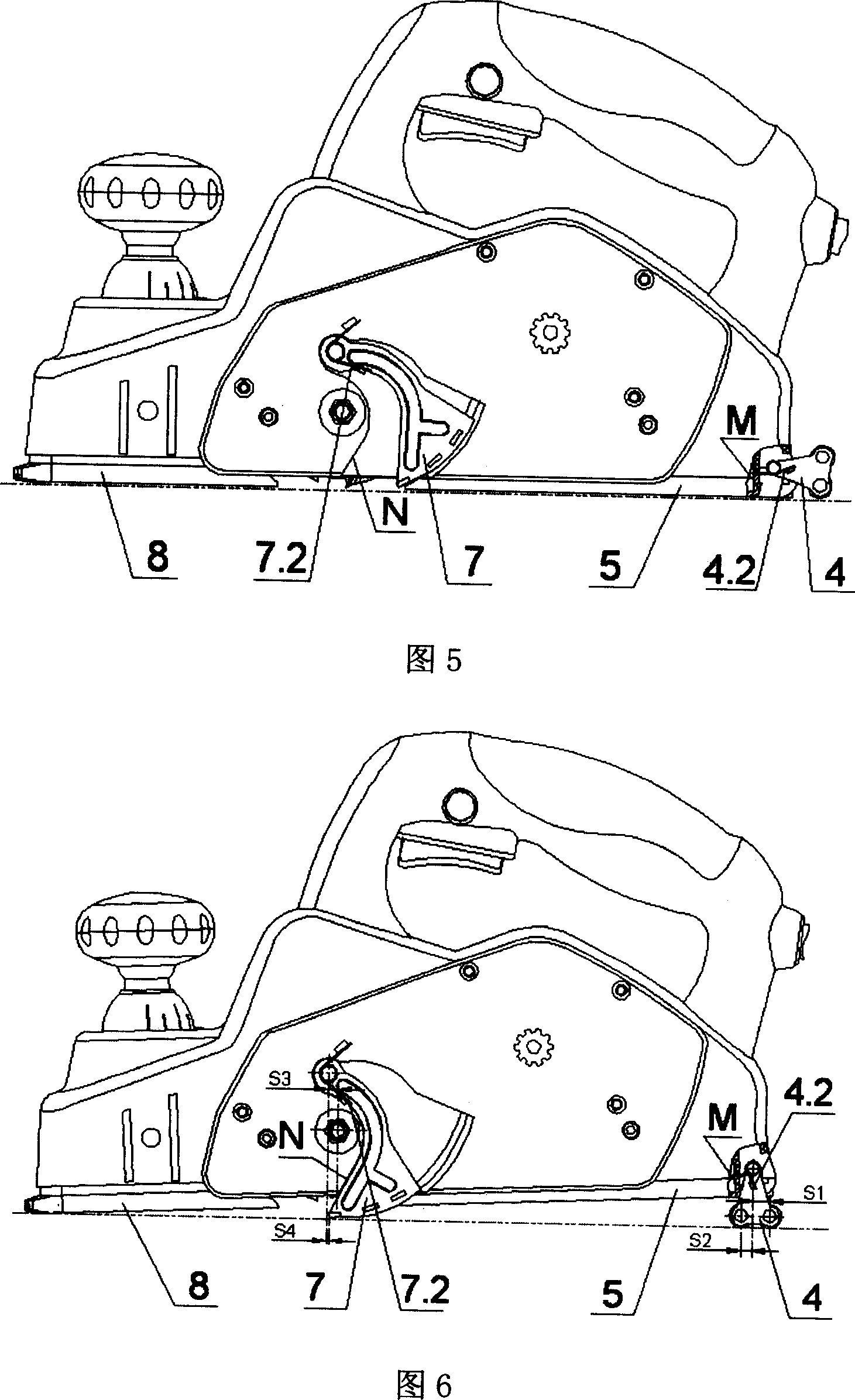

[0022] As shown in Figure 1 and Figure 2, a hands-free portable electric planer mainly includes a motor 10, a belt 9, a knife shaft 12, a blade 11, a bottom plate 5, an adjustment bottom plate 8, a depth adjustment knob 1, a switch 2, and a handle 3 , Roller bracket mechanism 4 and blade guard 7 etc. are formed, and roller bracket mechanism 4 is positioned at machine afterbody, and the shield of blade guard 7 rotates to below the blade.

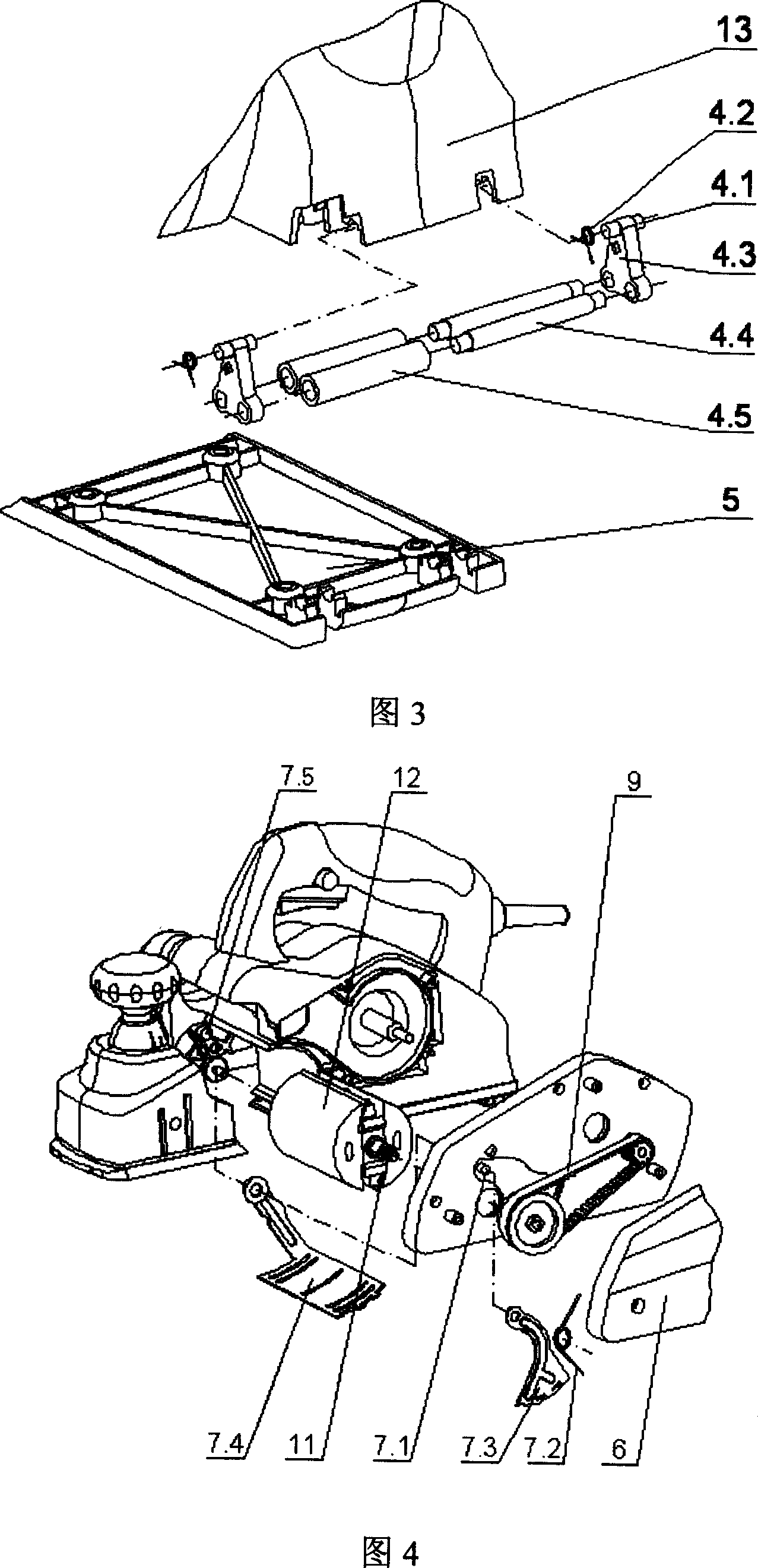

[0023] As shown in Figure 3, the portable electric planer is equipped with at least one roller bracket mechanism, and the roller bracket mechanism 4 is composed of bracket 4.3, bracket rotating shaft 4.1, roller shaft 4.4, roller 4.5 and bracket torsion spring 4.2, etc., wherein There are at least two roller shafts and at least one torsion spring. The bracket rotating shaft 4.1 is located on the upper part of the bracket 4.3 and hinged in the mounting hole between the machine tail casing 13 and the bottom plate 5. The roller bracket mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com