Water jet propelling device guide blade processing method

A technology of water jet propulsion and processing method, which is applied in the directions of propulsion components, ship propulsion, metal processing equipment, etc., can solve the problems of scrap guide vane 1, difficult to find the oil hole 25, affecting the efficiency of the jet pump, etc. Machining efficiency and machining accuracy, improvement of type value control ability, and the effect of improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

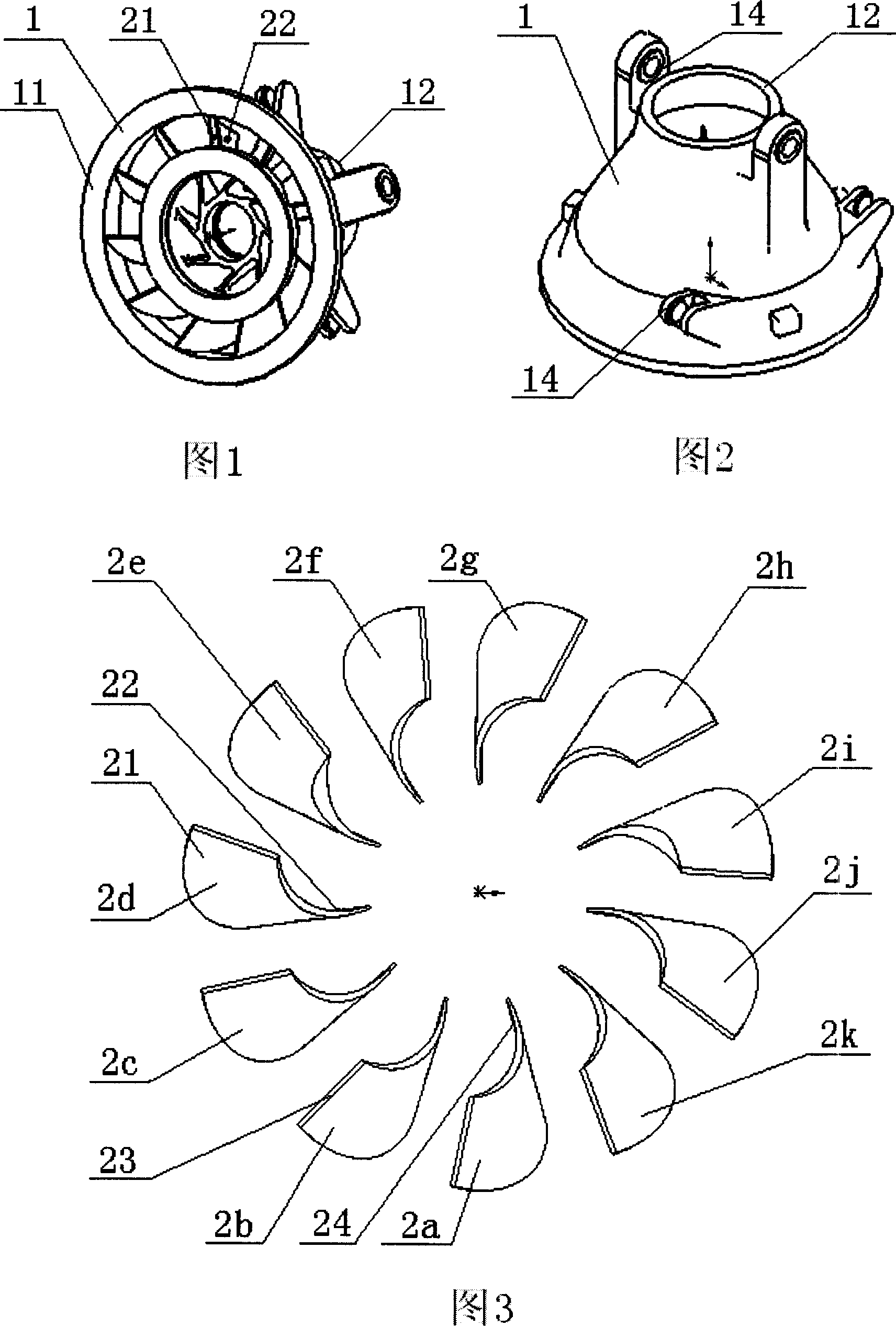

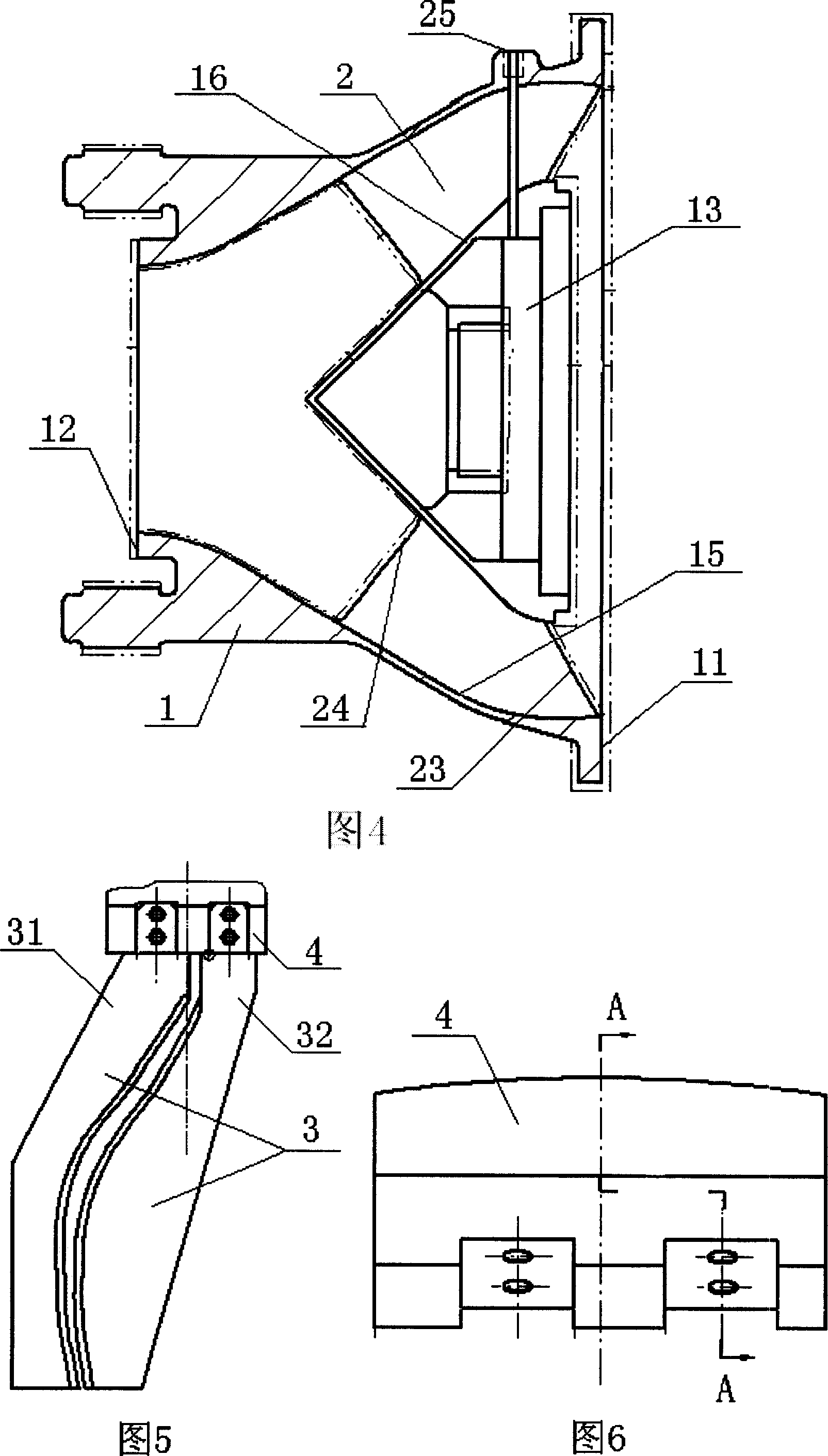

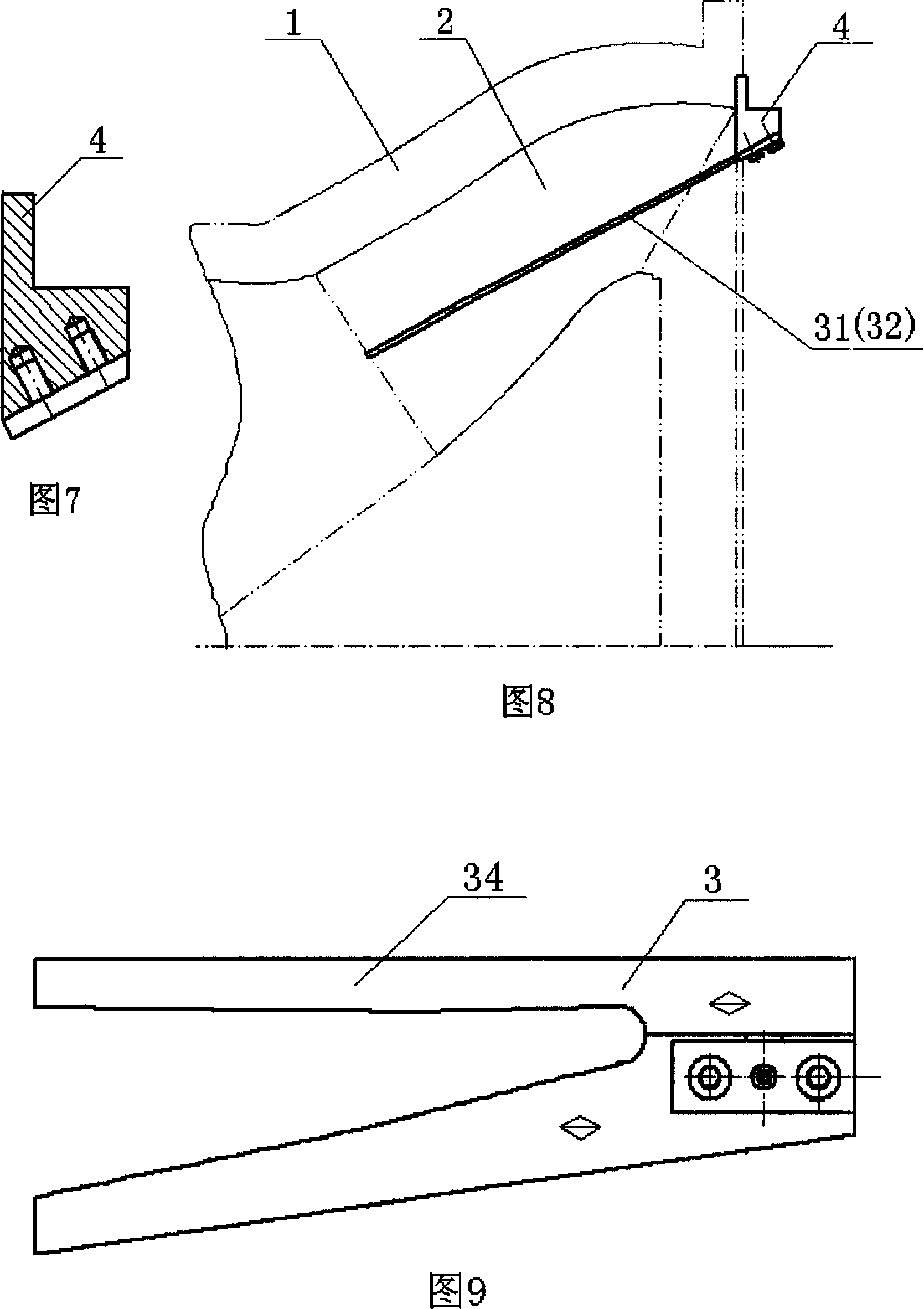

[0041] Embodiment: The processing method of guide vane body 1 comprises the following steps:

[0042] 1. Blank casting

[0043] The shapes of the guide vane body 1 and the guide vane 2 are shown in FIG. 1 , FIG. 2 , FIG. 3 and FIG. 4 . If there is no margin on the surface of the guide vane 2 during casting of the guide vane body 1, it is not only difficult to ensure the line shape and indexing, but also prone to cracks; because the space between two adjacent guide vanes 2 is small, it is not conducive to the entire curved surface. For CNC machining, excessive placement of the margin will increase the difficulty of machining. In order to reduce the difficulty of processing and improve the yield of products, we put 2 to 3 mm margin on the suction surface 21 and pressure surface 22 of the guide vane 2 during casting, and at the same time, the water inlet edge 23 and the water outlet edge 24 are thinner and easier The processing part is processed according to the casting routine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com