Multi-energy source integration hybrid platform system

A hybrid and multi-energy technology, applied in general control systems, control/regulation systems, electric vehicles, etc., can solve problems such as low power density, low cost, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0117] Example 1: Multi-energy integrated hybrid platform system for a new fuel cell hybrid bus

[0118] Figure 17 Shown is the schematic diagram of the developed new fuel cell hybrid electric bus. The power system components are: fuel cell engine (FCE) and its control system (FCS), DC-DC converter (DCDC) and its control system (DCC), nickel-hydrogen battery and battery management system (BMS), drive motor assembly and Its controller (MCU), hydrogen temperature and pressure detection unit (HPS) and vehicle controller (VCU), the power system communication uses TTCAN, and the VCU control algorithm cycle is 10ms. The main parameters and vehicle performance are listed in the following table (Table 6).

[0119] Table 6 Parameters of a fuel cell series hybrid vehicle

[0120] powertrain components parameter name parameter value fuel cell engine Rated power / kW 65 Overload power / kW 88 Voltage range / V 330~450 Noise / dB 80 DCDC Rat...

example 2

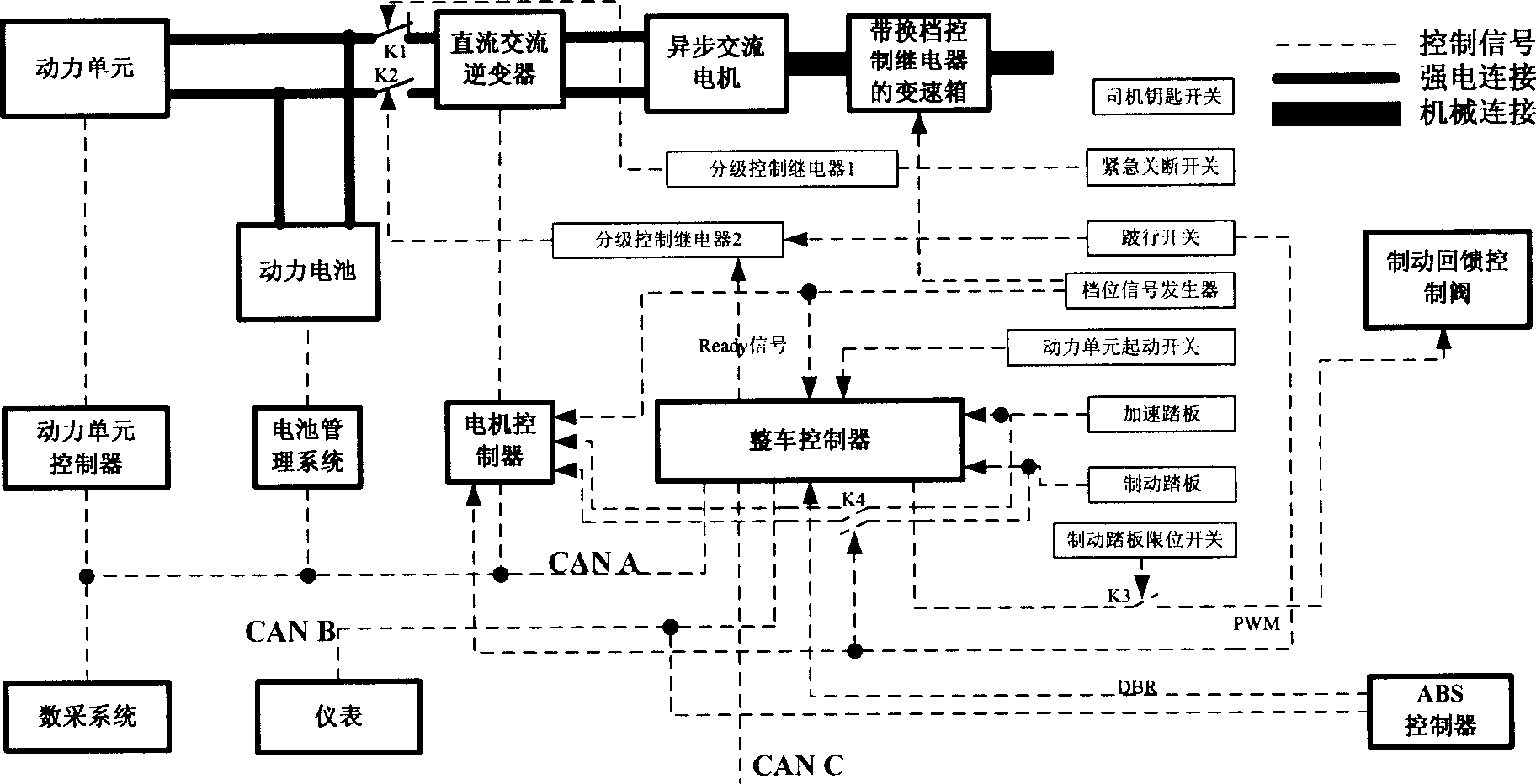

[0121] Example 2: Multi-energy integrated hybrid platform system for a new diesel engine hybrid bus

[0122] Figure 18 Shown is a schematic diagram of the developed new diesel engine hybrid bus. The power system components are: diesel engine and its controller (ECU), excitation plate, rectifier, nickel-hydrogen battery and battery management system (BMS), drive motor assembly and its controller (MCU) and vehicle controller (VCU), The power system communication is the traditional CAN conforming to the J1939 protocol, and the VCU control algorithm cycle is 20ms. The main parameters and vehicle performance are listed in the table below.

[0123] Table 7 Parameters of a series diesel engine hybrid vehicle

[0124] powertrain components parameter name parameter value Diesel engines model SOFIM2.8L category High pressure common rail diesel engine Maximum torque 320N.m@1500r / m Best fuel consumption / speed 210g / kW.h@1500-1800r / m ...

example 3

[0126] Example 3: New natural gas engine hybrid bus

[0127] Figure 19 Shown is the schematic diagram of the developed new natural gas engine hybrid electric bus. The power system components are: natural gas engine and its controller (ECU), excitation plate, rectifier, nickel-hydrogen battery and battery management system (BMS), drive motor assembly and its controller (MCU), and vehicle controller (VCU) , The power system communication is the traditional CAN in line with the J1939 protocol, and the VCU control algorithm cycle is 20ms. The main parameters and vehicle performance are listed in the table below.

[0128] Table 10 Parameters of series hybrid components of a natural gas engine

[0129] powertrain components parameter name parameter value natural gas engine model 4CT Displacement (L) 5.3 Rated power (kW) / speed (r / min) 118~132 / 2300 Maximum torque (N.m) / speed (r / min) 580~680 / 1300~1500 Combustion System Spark i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com