Driving control system for overturn row-by-row and its method and LED display screen

A technology of LED display and flip control, applied in energy-saving control technology, static indicators, semiconductor/solid-state device manufacturing, etc., can solve the problems of large instantaneous current changes, low hardware utilization, voltage noise, etc., and achieve instantaneous reduction of current Variation amplitude, avoiding voltage noise, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

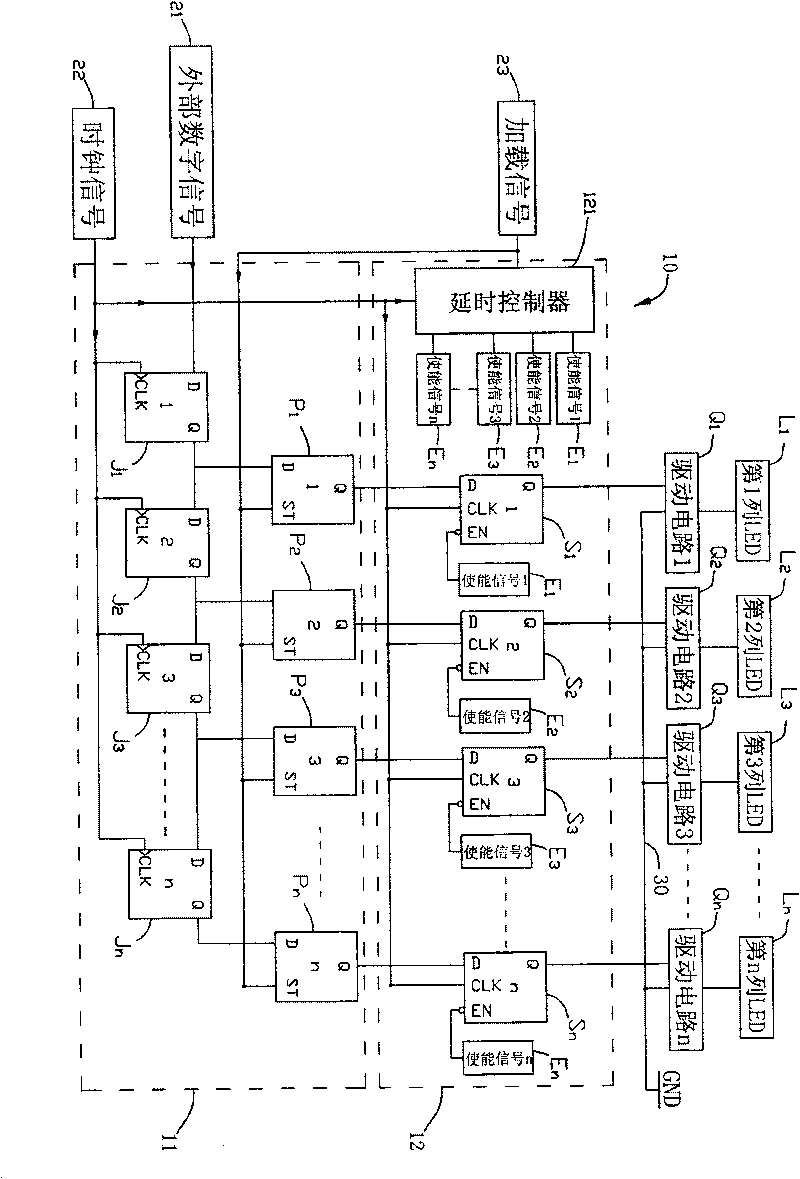

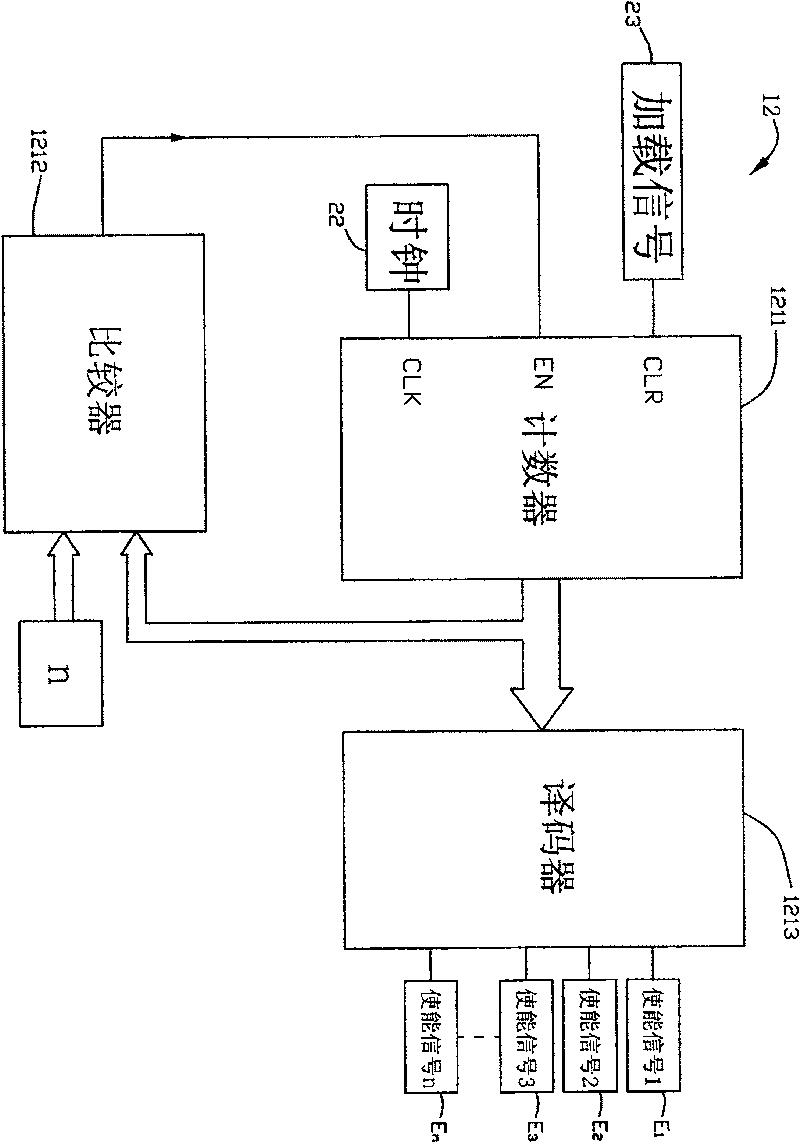

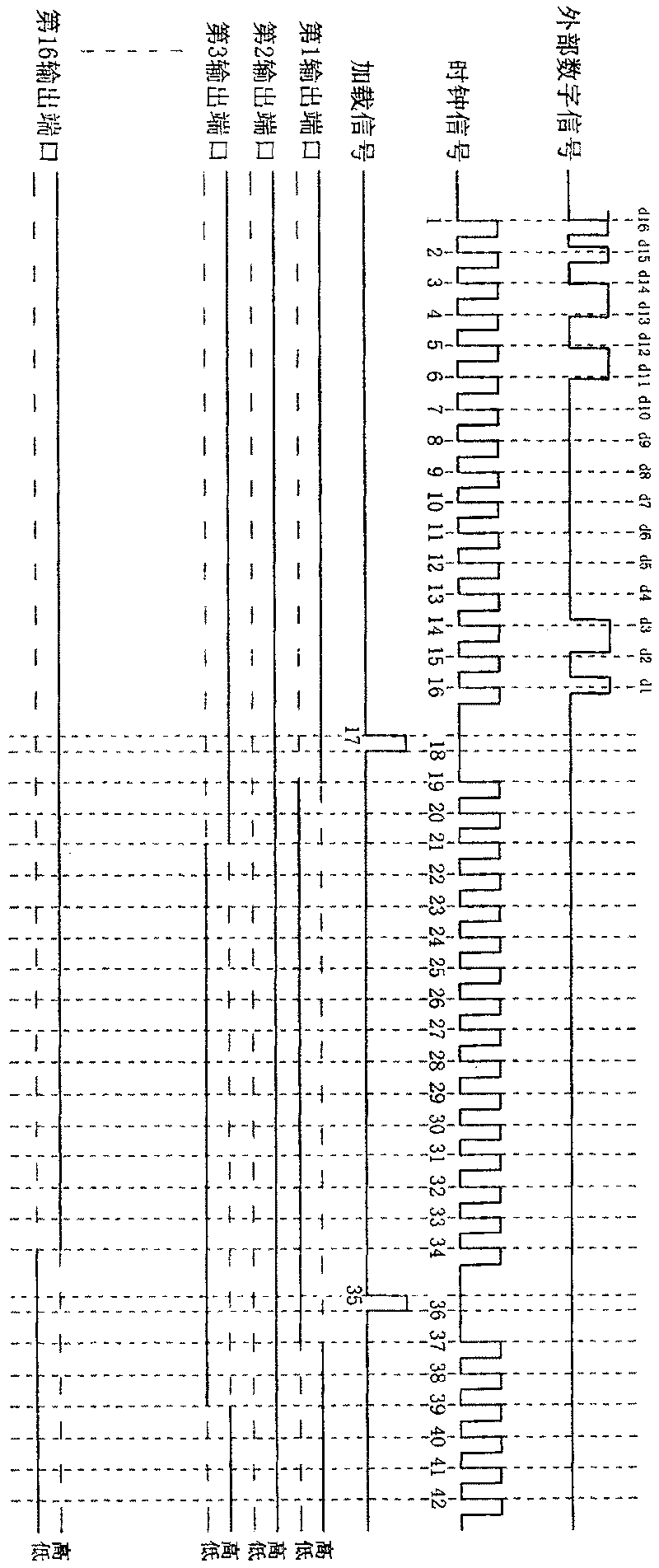

[0044] figure 1 Shown is a schematic diagram of the circuit principle of the column-by-column inversion control device 12 of the present invention. In this embodiment, the column-by-column inversion control device 12 is used for the LED display screen 10, and the LED display screen 10 is mainly used for receiving external images, characters, etc. The signal is then controlled to drive the LED lamps L1, L2, L3...Ln to be displayed on the LED display screen, but it is not limited thereto.

[0045] The LED display screen 10 of this embodiment mainly includes several LED lamps L1, L2, L3...Ln, several driving circuits Q1, Q2, Q3...Qn, an information collection circuit 11, and a column-by-column flip control device 12, which will be described in detail below . The drive circuits Q1, Q2, Q3...Qn, the information collection circuit 11 and the column-by-column inversion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com