Wafer-level opto-electronic testing apparatus and method

A testing device, optoelectronic testing technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc. Testing is not a matter of waiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

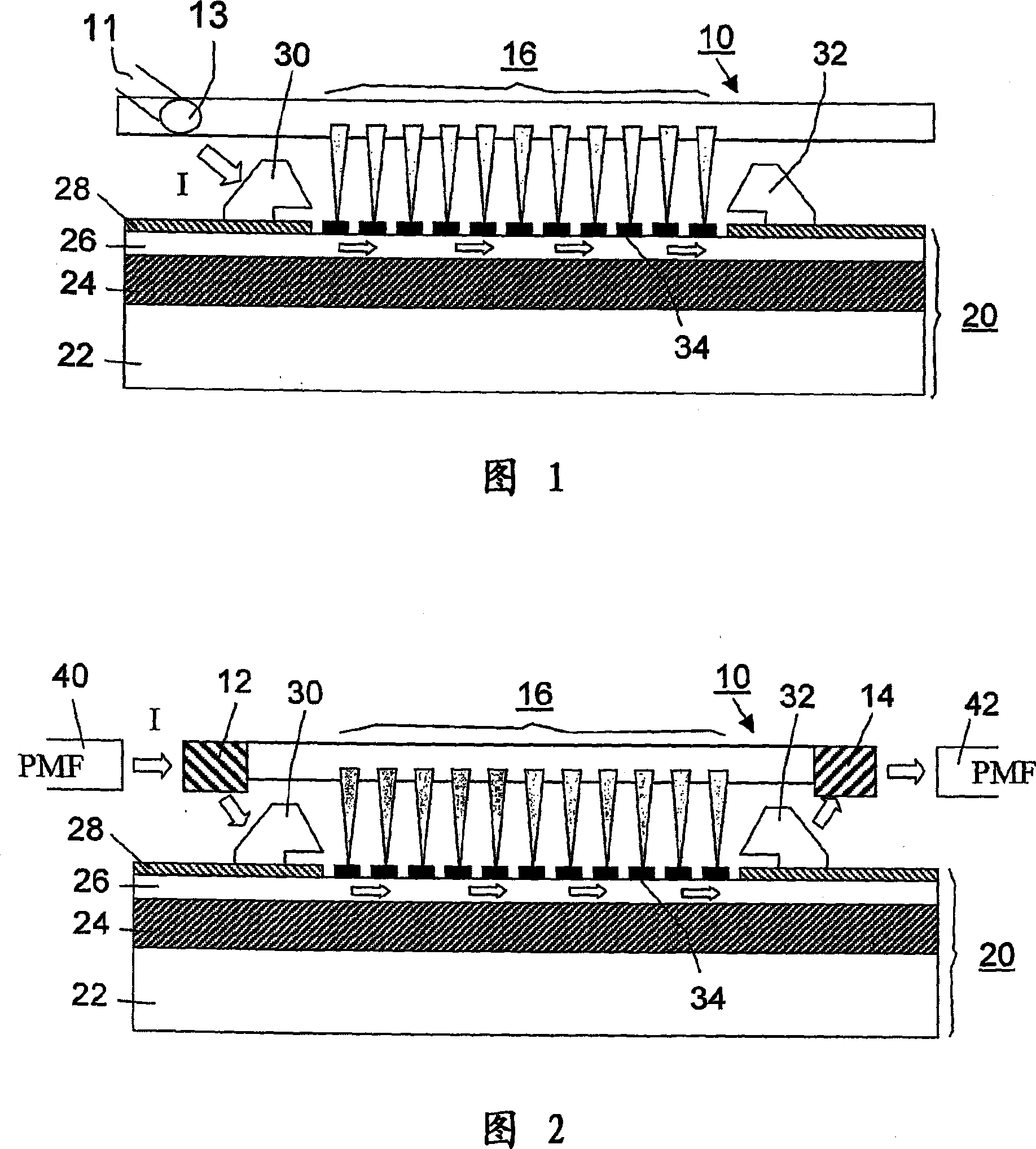

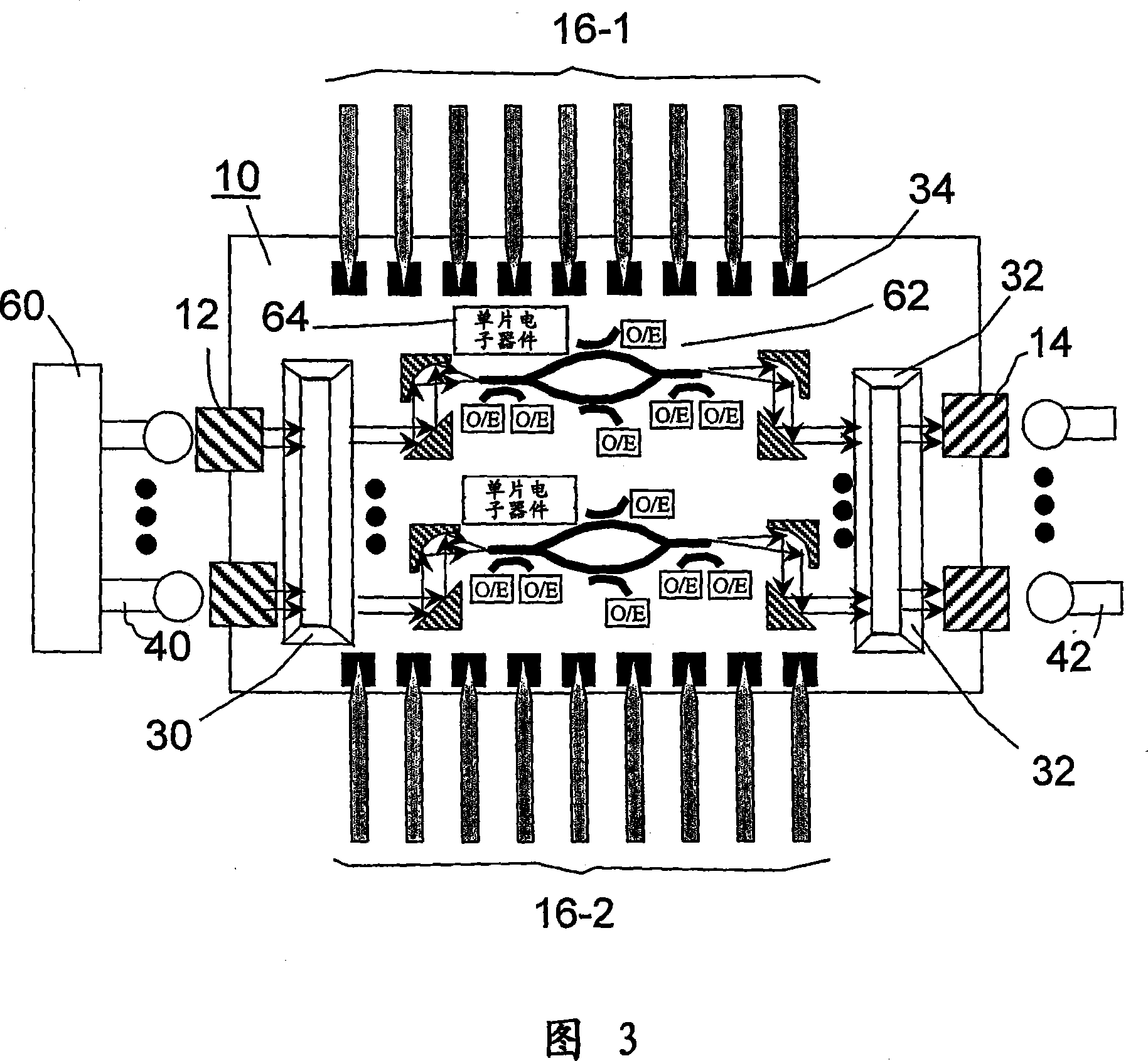

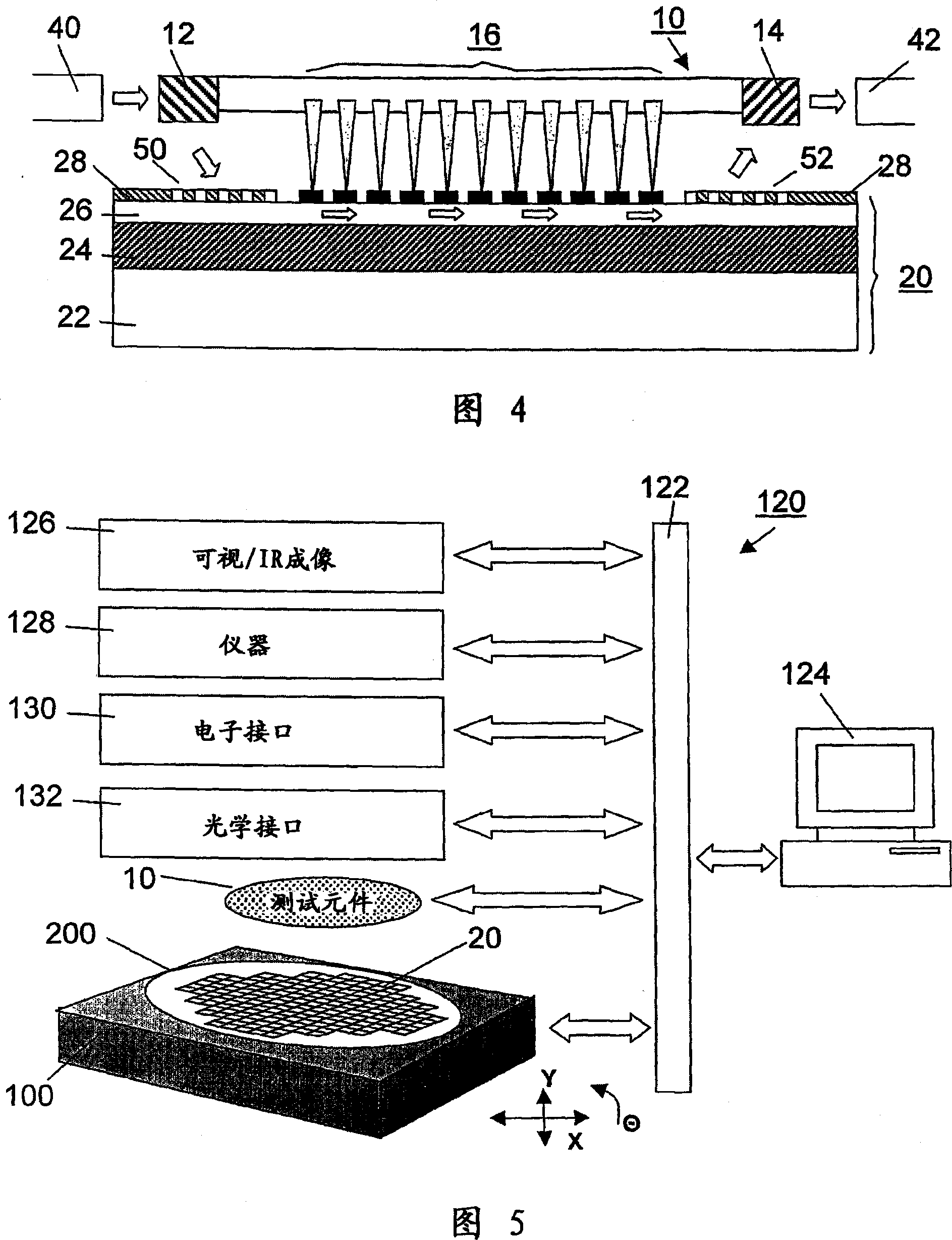

[0020] As briefly mentioned above, one of the greatest challenges in the development of optical test elements for SOI-based optical structures is the need to reliably couple light beams into very thin waveguides under test in a repeatable manner. The angle required for light to enter a thin waveguide is known to be a strong function of the thickness of the waveguide and the wavelength of the optical signal (ie, the angle of the optical mode entering the SOI structure needs to be well controlled to excite the eigenmodes in the waveguide). An aspect of the present invention is the ability to "tune" the wavelength of a test signal over a range such that acceptable coupling can be reliably achieved on a repeatable basis. The ability to monitor and "tune" the test wavelength in accordance with the present invention is considered wafer-level testing of optoelectronic components since process variations can vary the thickness of the waveguide layer, and the associated evanescent coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com