Heat sink

A heat dissipation device and heat dissipation fin technology, which is applied in the direction of heat dissipation fins, indirect heat exchangers, heat exchange equipment, etc., can solve the problems that the airflow cannot blow into the flow rate, the ambient temperature rises, and is slow, so as to ensure smoothness, Improve heat dissipation performance and increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The heat dissipation device of the present invention is used to dissipate heat from electronic components such as a central processing unit (not shown in the figure).

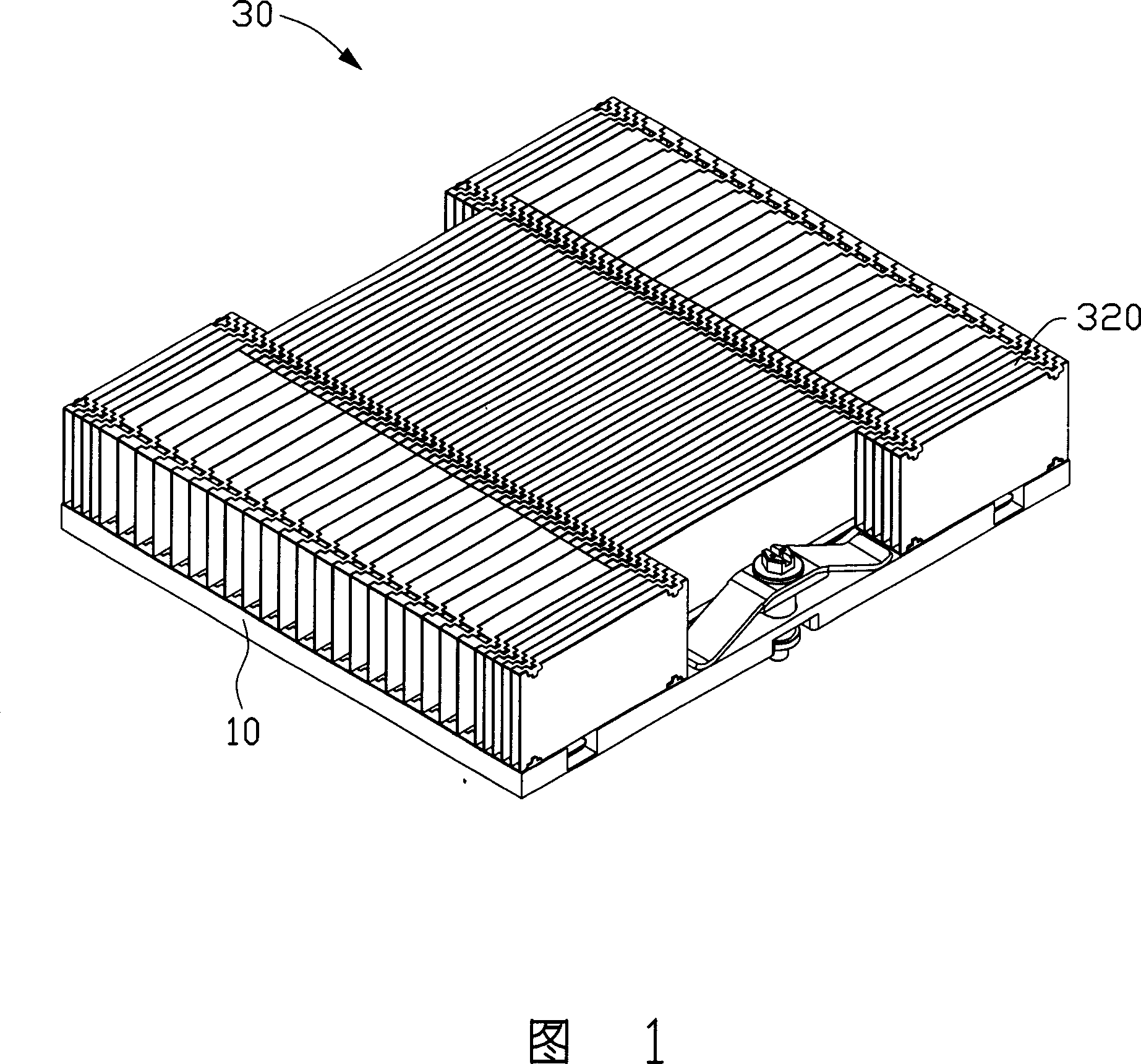

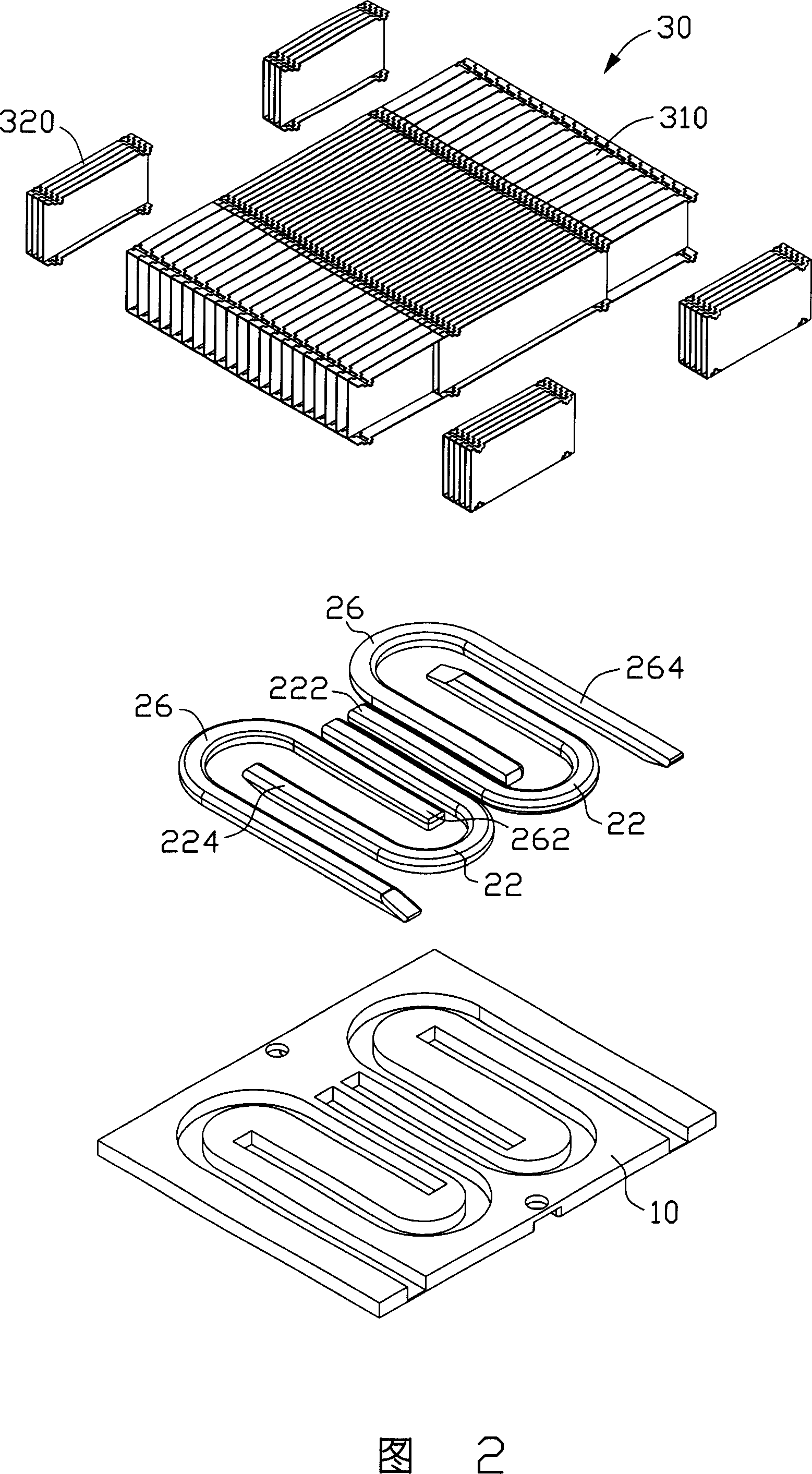

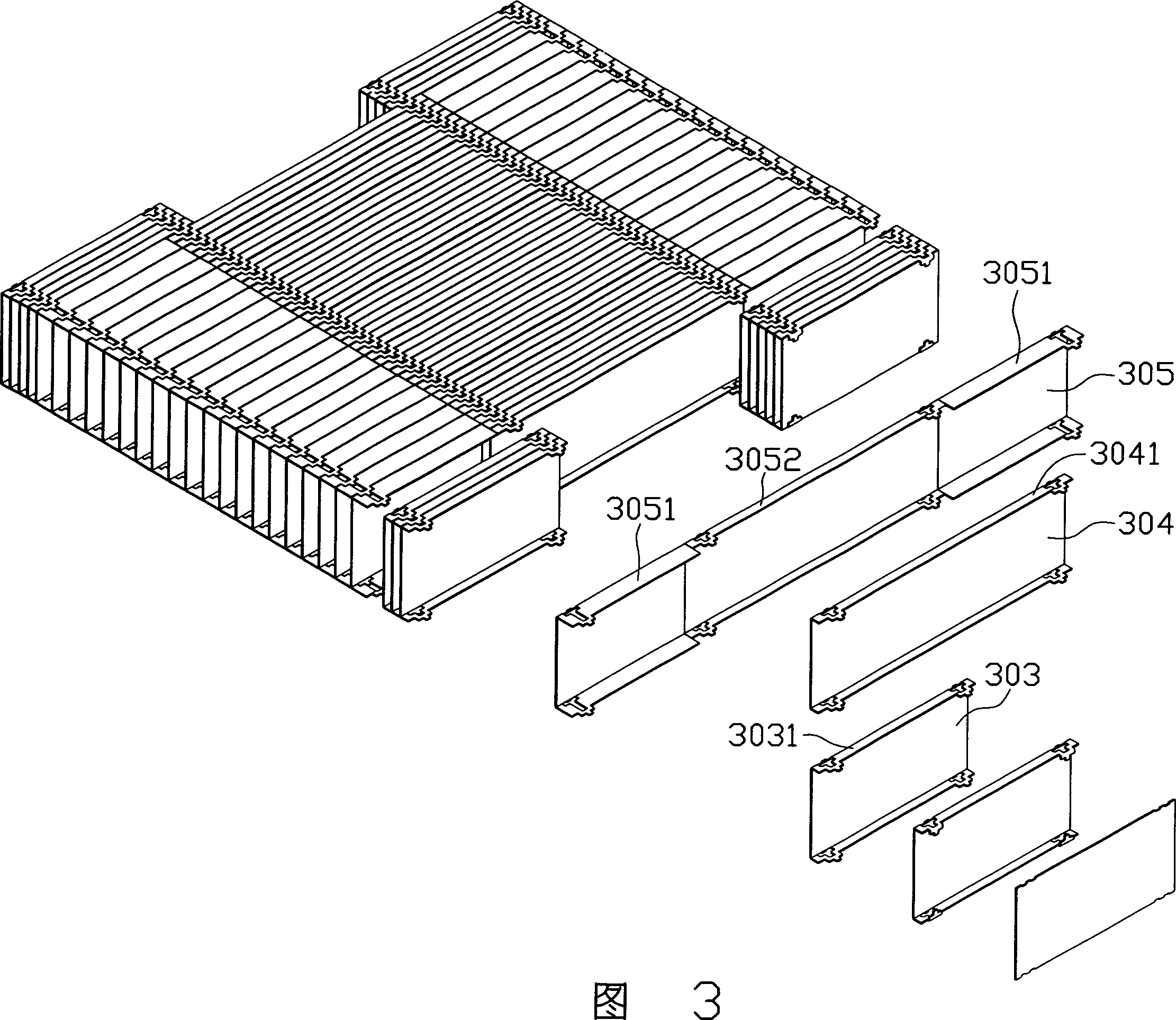

[0015] 1 to 4 show the first embodiment of the heat dissipation device of the present invention. The heat dissipation device includes a base plate 10 , a heat sink set 30 disposed on the base plate 10 , and two sets of heat pipes 22 , 26 sandwiched between the base plate 10 and the heat sink set 30 .

[0016] The bottom plate 10 is made of materials with good thermal conductivity, such as copper and aluminum, and its bottom surface is in contact with electronic components (not shown) to absorb heat generated by the electronic components during operation. Both the first heat pipe 22 and the second heat pipe 26 are bent into a U shape and are flat. The first heat pipe 22 includes an evaporating section 222 and a condensing section 224 with equal lengths, and the second heat pipe 26 includes an evaporating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com