Chamfering tool dedicated for porous inside

A technology of chamfering and cutting tools, which is applied in the field of special cutting tools for chamfering in holes, can solve the problems of high processing experience requirements, difficulty in mass production, high probability of waste products, etc., achieve simple and fast conversion operations, improve processing efficiency, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

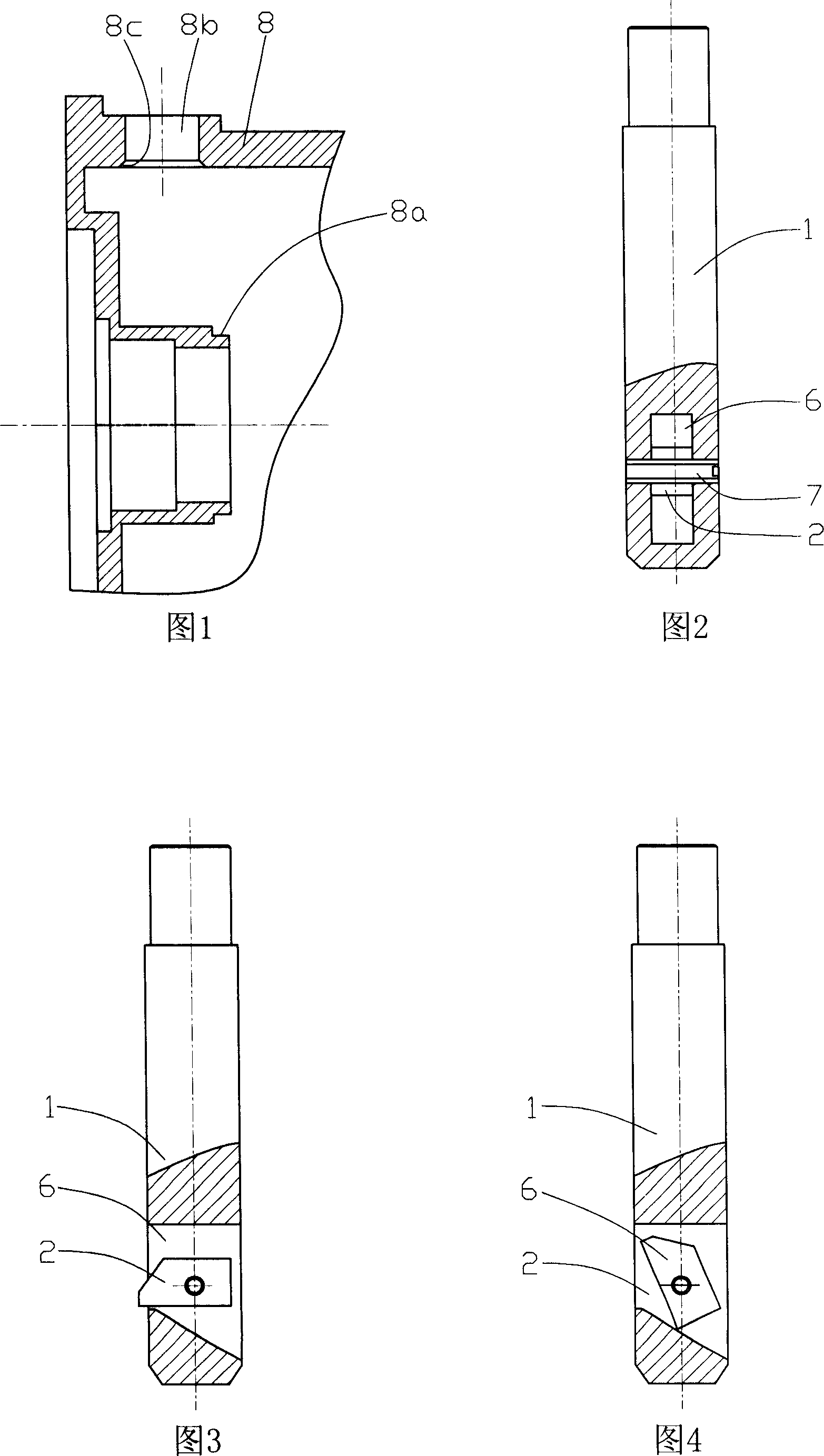

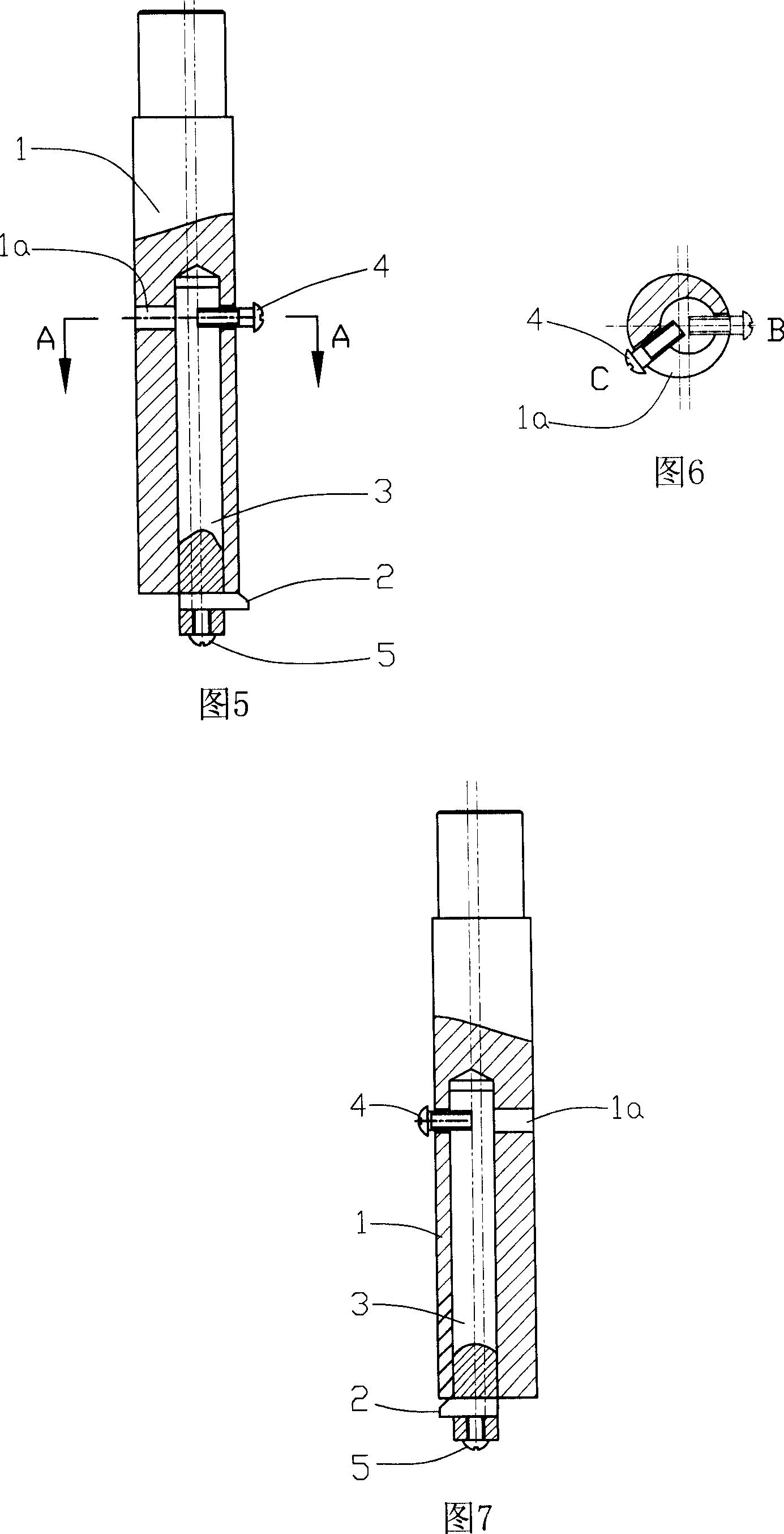

[0023] As shown in FIG. 5 , FIG. 6 and FIG. 7 , the present invention is composed of a first cutter bar 1 , a blade 2 , a second cutter bar 3 , a toggle screw 4 , and a tightening screw 5 . The bottom surface of the first tool bar 1 is provided with an eccentric hole along the direction of its axis line, and the center line of the eccentric hole is deviated from the axis line of the first tool bar 1 . In the middle of the outer circumference of the first cutter bar 1, there is a shifting groove 1a which communicates with the upper part of the eccentric hole. A second cutter bar 3 is installed in the eccentric hole, the second cutter bar 3 and the first cutter bar 1 are gap-fitted, and a blade is installed at the position where the lower end of the second cutter bar 3 protrudes from the bottom surface of the first cutter bar 1 A square hole, the blade 2 is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com