Manganese chloride dehydration method and method for promoting (cyclopentadienyl)manganese compound yield

A technology of manganese compounds and manganese chloride, applied in chemical instruments and methods, manganese halides, metallocenes, etc., can solve problems affecting the yield of manganese compounds, and achieve the effect of improving the yield of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

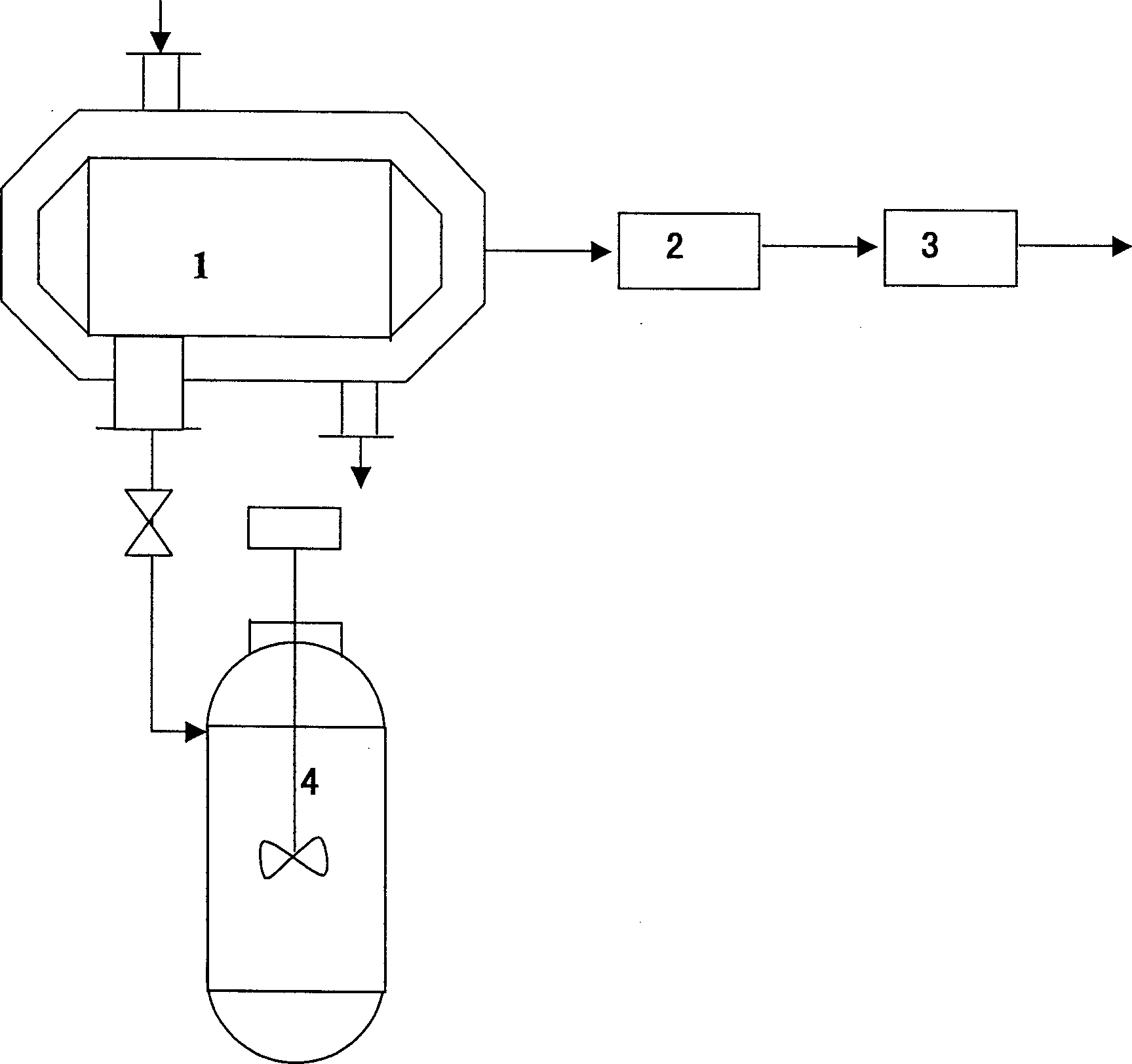

[0019] Embodiment: referring to accompanying drawing, take the production of methylcyclopentadiene manganese tricarbonyl (MMT) gasoline octane number synergist as an example, commercially available manganese chloride (about about 1% water content) is put into double cone In the cylindrical vacuum dryer 1, the dryer is continuously rotated, and the temperature is raised to 200-250°C. At the same time, it is pumped to a vacuum degree of about -0.09Mpa through the connected vacuum pump 3, and the online moisture detection in the series-connected vacuum pipeline Instrument 2 detects the moisture in the exhaust gas until it is stable at 200ppm or below, keeps the temperature for 3-5 hours, and replaces it with dry gas several times, and removes as much moisture as possible from the dryer to obtain anhydrous water with a moisture content of less than 200ppm. manganese chloride. Then open the discharge valve on the drier, and put it into the carbonylation kettle to carry out the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com