Air feed and cooling system of porton exchange film fuel battery

A proton exchange membrane and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of increasing system complexity, increasing cost, reducing system power density and weight density, etc. Cost, simplified air supply and cooling system, and the effect of increasing power density and weight density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

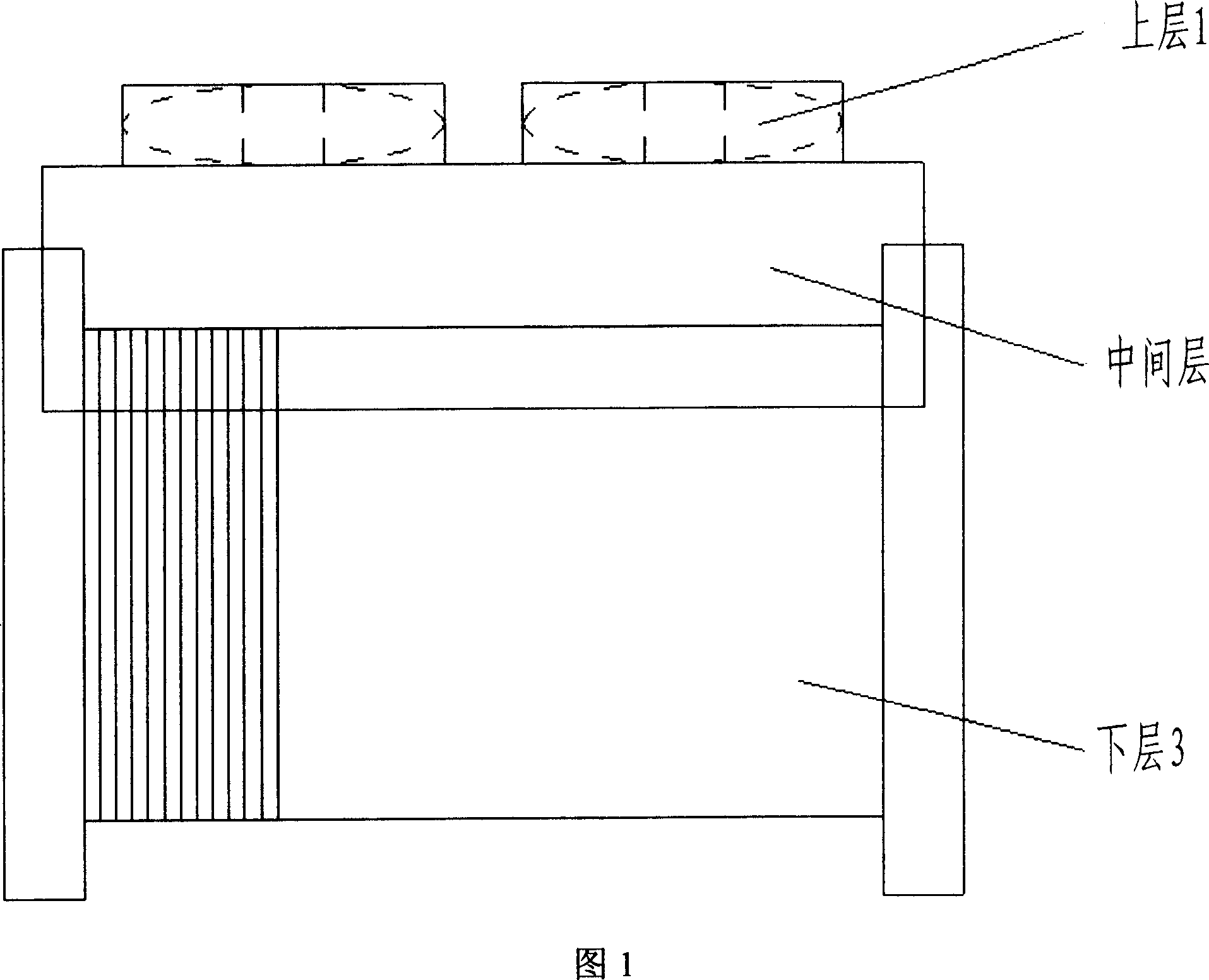

[0024] As shown in Figure 1, a proton exchange membrane fuel cell system designed using the above technology is divided into three layers. The upper layer 1 is an axial fan, the middle layer 2 is a wind shield, and the lower layer 3 is a proton exchange membrane fuel cell stack. .

[0025] The upper layer 1 contains two axial fans, each with a size of 80×80 (mm×mm).

[0026] The middle layer 2 is a transparent plastic windshield for fixing the axial fan and forming a relatively closed space on the upper side of the battery.

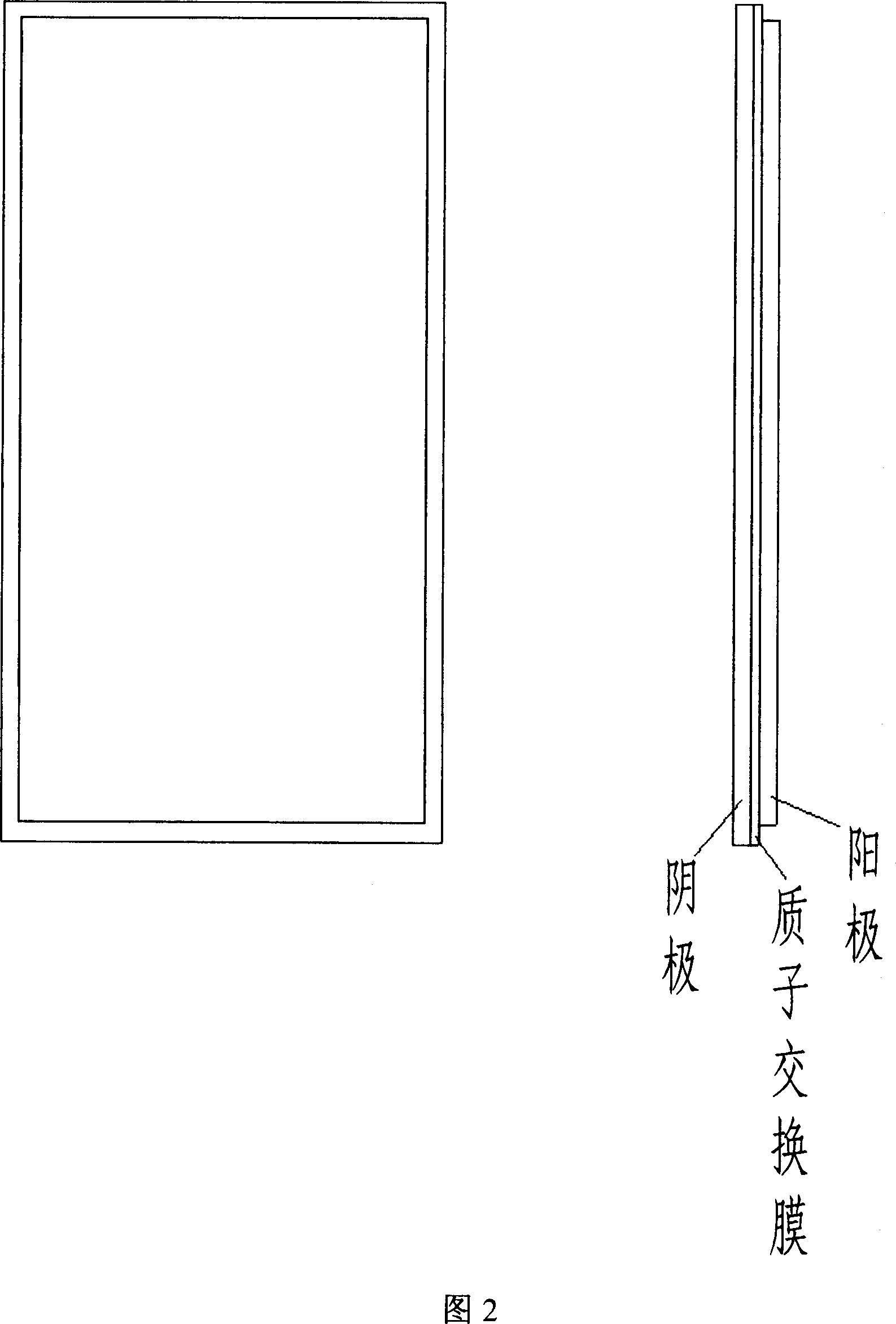

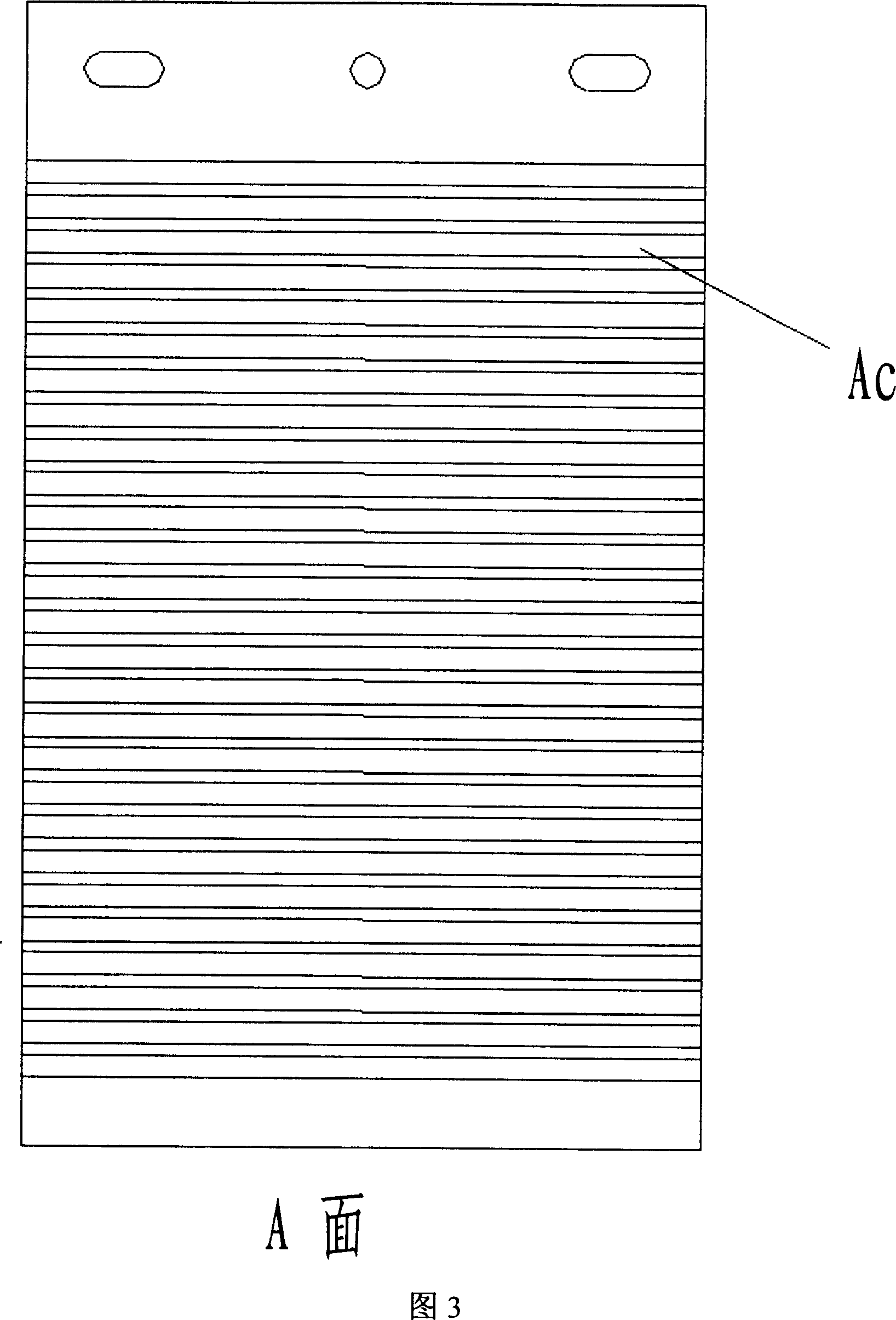

[0027] The lower layer 3 is a proton exchange membrane fuel cell stack whose internal structure is shown in Figures 2-6. Figure 2 is the proton exchange membrane electrode; Figures 3 and 4 are the sides A and B of the cathode plate, side A is the linear air guide groove of the cooling unit, and side B is the linear air guide groove of the reaction unit. And the diversion grooves are directly penetrated from one side of the pole plate to the other side; Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com