Three-dimensional cultivation frame beneficial for heat dissipation of light source

A technology of three-dimensional cultivation racks and cultivation racks, which is applied in cultivation, soilless cultivation, and agricultural gas emission reduction, etc. It can solve the problems of plant factory benefits, costs, and production efficiency, and achieve simplified cooling methods and difficulties, and reduced temperature control. Cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

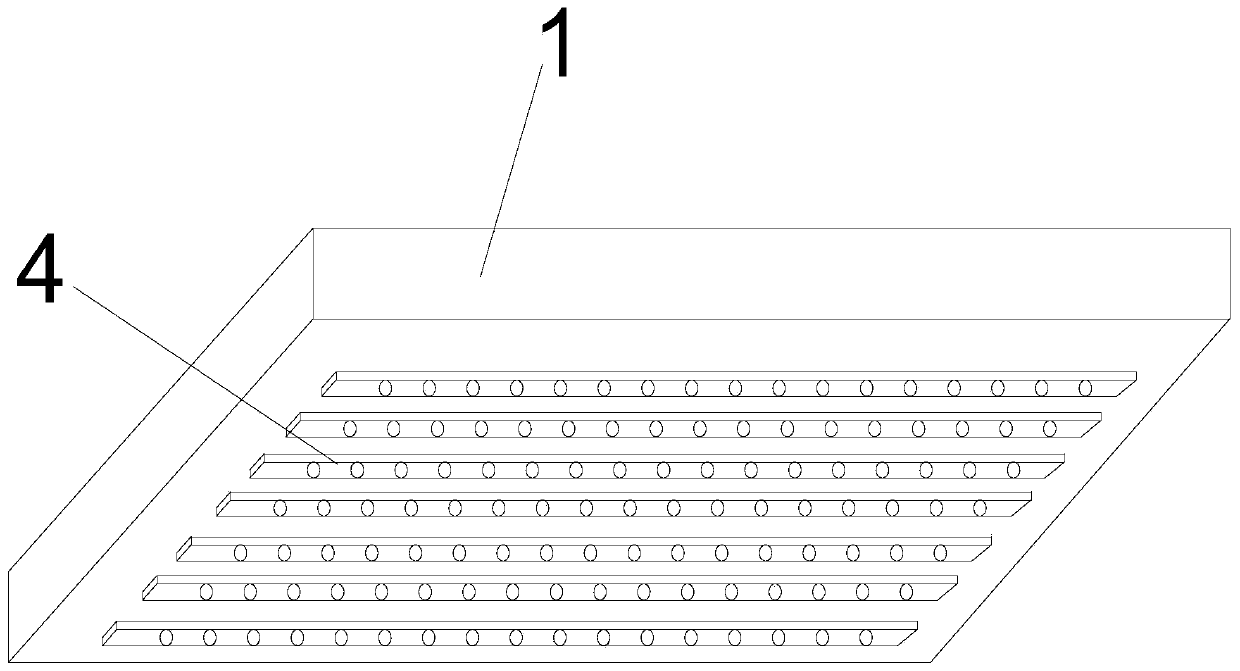

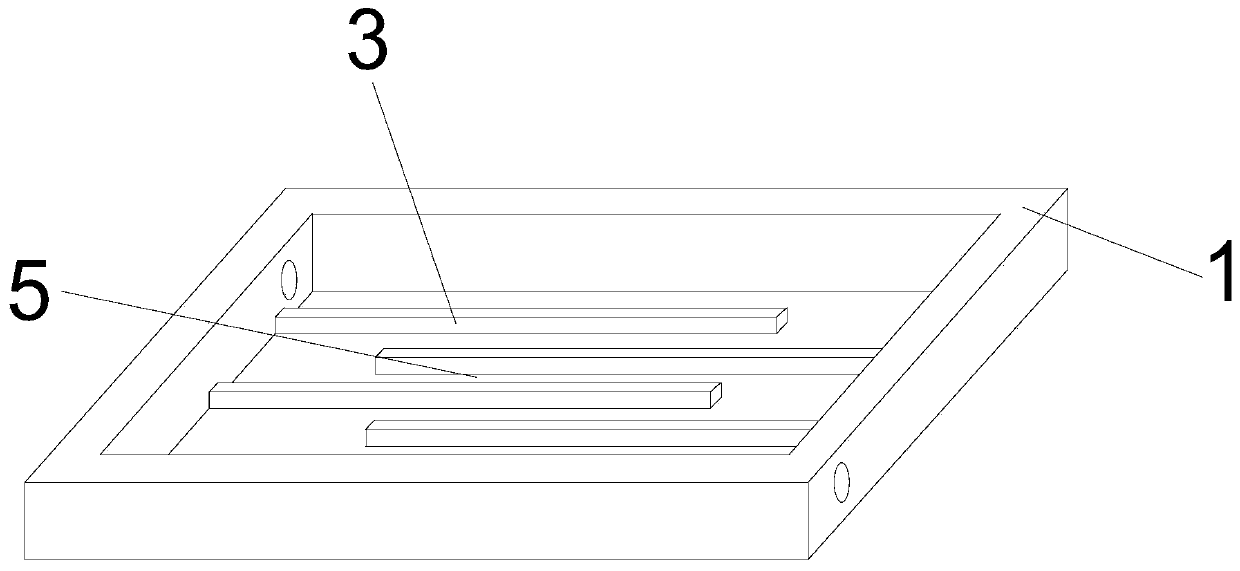

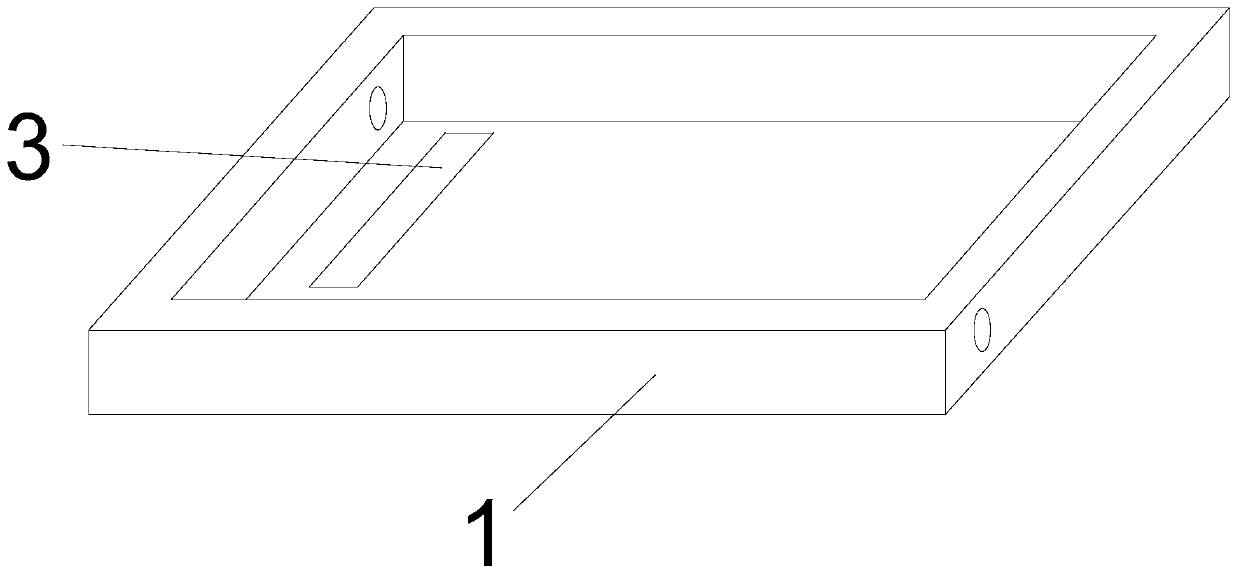

[0037] see figure 1 , figure 2 , Figure 5 , Figure 8 , the three-dimensional cultivation rack of the present embodiment a kind of novel light source 4 heat dissipation modes, comprise cultivation rack 6, cultivation nutrient solution tank 1, light source 4 and the cooling fin 3 that links to each other with light source 4, described cultivation nutrient solution tank 1 is arranged on the cultivation rack 6, the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, the cultivation nutrient solution tank 1 is arranged as a cuboid, and the two symmetrical short side walls of the cultivation nutrient solution tank 1 are provided with a liquid inlet and a liquid outlet respectively , the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, and the heat sink 3 is located in the cultivation nutrient solution tank 1 and directly contacts the nutrient solution in the cultivation nutrient solution tank 1. Each fin ...

Embodiment 2

[0045] see figure 1 , image 3 , Figure 5 , Figure 8 , the three-dimensional cultivation rack of the present embodiment a kind of novel light source 4 heat dissipation modes, comprise cultivation rack 6, cultivation nutrient solution tank 1, light source 4 and the cooling fin 3 that links to each other with light source 4, described cultivation nutrient solution tank 1 is arranged on the cultivation rack 6, the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, the cultivation nutrient solution tank 1 is arranged as a cuboid, and the two symmetrical short side walls of the cultivation nutrient solution tank 1 are provided with a liquid inlet and a liquid outlet respectively , the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, and the heat sink 3 is located in the cultivation nutrient solution tank 1 and directly contacts the nutrient solution in the cultivation nutrient solution tank 1. Each fin 3...

Embodiment 3

[0053] see figure 1 , Figure 4 , Figure 5 , Figure 8 , the three-dimensional cultivation rack of the present embodiment a kind of novel light source 4 heat dissipation modes, comprise cultivation rack 6, cultivation nutrient solution tank 1, light source 4 and the cooling fin 3 that links to each other with light source 4, described cultivation nutrient solution tank 1 is arranged on the cultivation rack 6, the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, the cultivation nutrient solution tank 1 is arranged as a cuboid, and the two symmetrical short side walls of the cultivation nutrient solution tank 1 are provided with a liquid inlet and a liquid outlet respectively , the light source 4 is connected to the bottom of the cultivation nutrient solution tank 1, and the heat sink 3 is located in the cultivation nutrient solution tank 1 and directly contacts the nutrient solution in the cultivation nutrient solution tank 1. Each fin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com