Multi-element composite aerosol atomization device

An atomization device and aerosol technology, applied in the field of tobacco, etc., can solve the problems of low production efficiency, single taste, poor tobacco taste and mouthfeel simulation, and achieve the effect of increasing production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

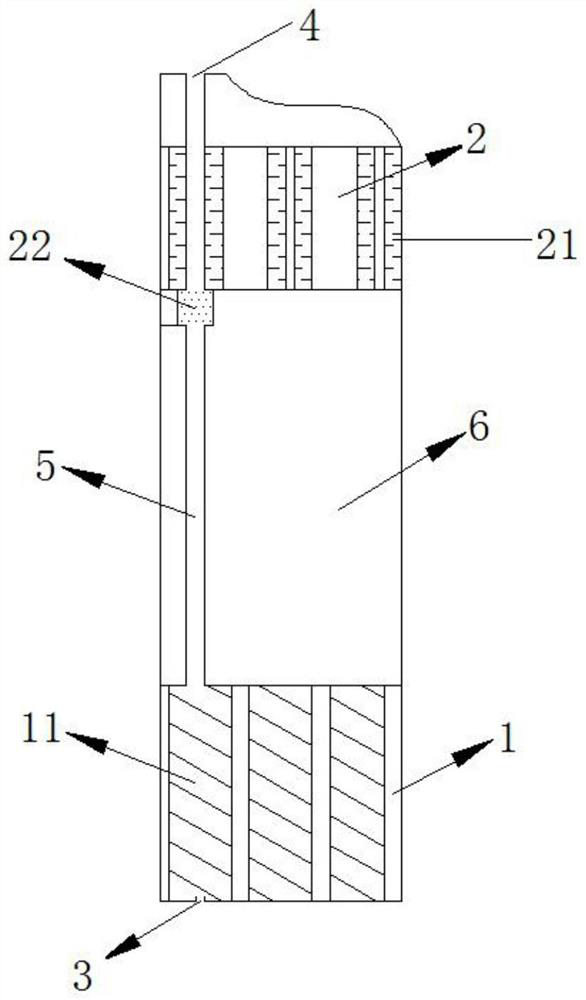

[0043] This embodiment provides a multi-component composite aerosol atomizing device, which includes a heating aerosol generating unit 1, an electric heating atomizing unit 2, an air inlet 3, a suction nozzle 4, an airway guide unit 5, a power supply and an electric Control unit 6 ; the heated aerosol generating unit 1 and the electrically heated atomizing unit 2 are in gas communication through the air channel guide unit 5 .

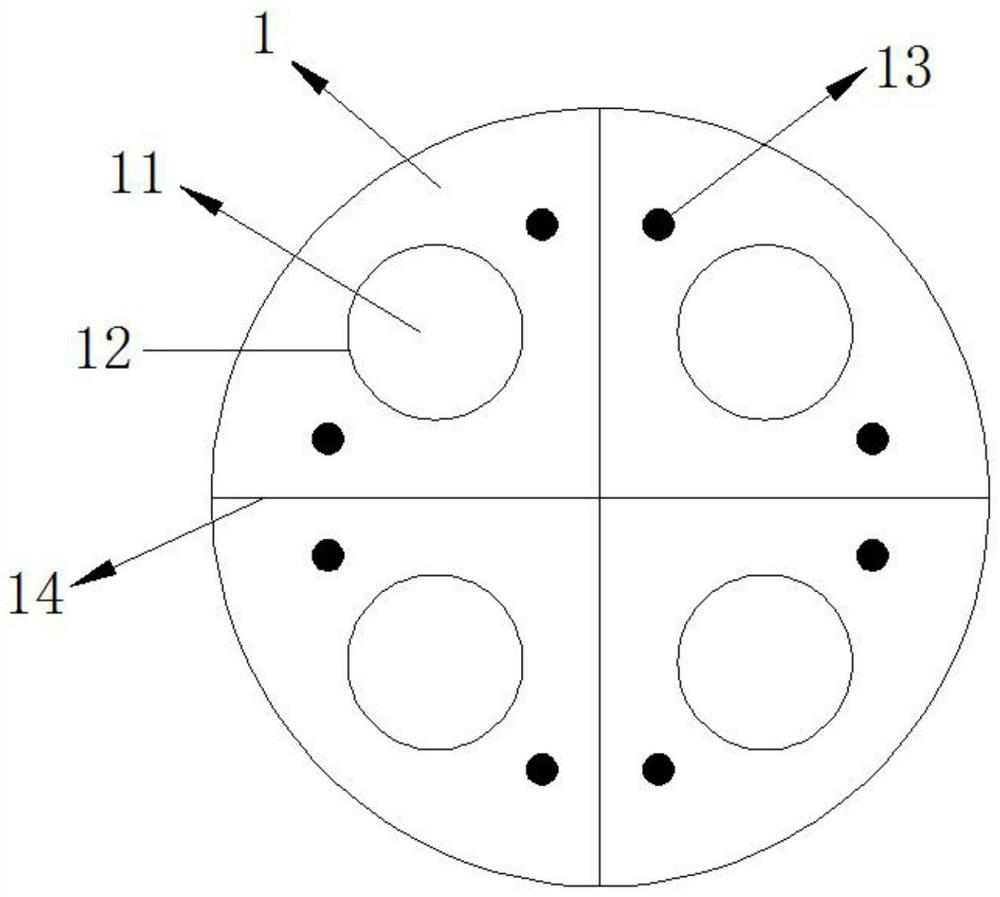

[0044] The heated aerosol generating unit 1 includes a plurality of aerosol generating substrate accommodating chambers 11, and the heated aerosol generating unit 1 can move with respect to the multi-component composite aerosol atomizing device, so as to accommodate different aerosol generating substrates. The cavity 11 is opposite to the airway guide unit 5; and / or, the electrically heated atomization unit 2 includes a plurality of atomization substrate accommodating cavities 21, and the electrically heated atomization unit 2 can be used for the multi-c...

Embodiment 2

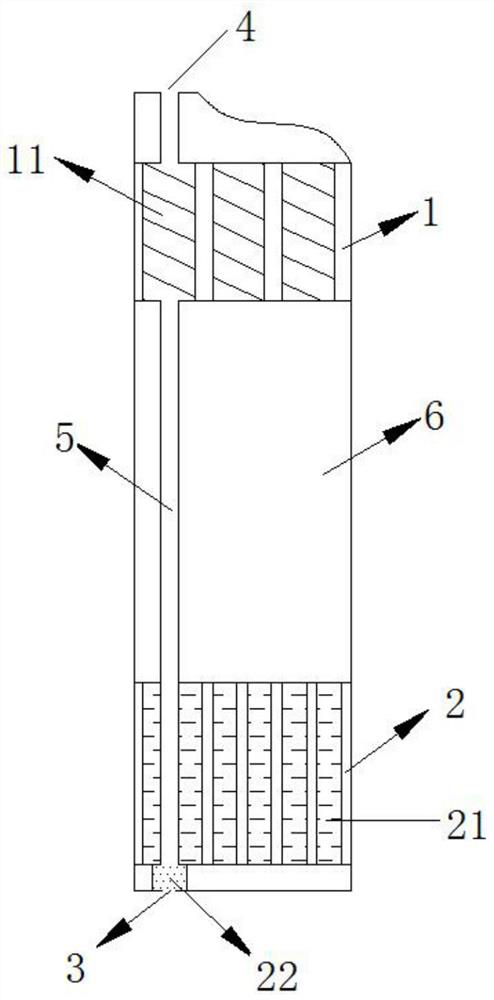

[0049] The difference between the multi-component composite aerosol atomizing device of this embodiment and the embodiment 1 is that the electrically heated atomizing unit 2 is located upstream of the heated aerosol generating unit 1, and the gas enters through the air inlet 3, and then passes through the The electrically heated atomizing unit 2 , the air channel guide unit 5 , and the heated aerosol generating unit 1 flow out through the suction nozzle 4 . In this case, the heating aerosol generating unit 1 is not provided with a separate heating component, and the atomized aerosol generated by the electrically heated atomizing unit 2 is eluted from the heating aerosol generating unit 1 and then flows out through the suction nozzle 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com