Cascade cyclone separator

A cyclone separation device, cascading technology, applied in the direction of the cyclone device, the device whose axial direction of the swirl can be reversed, etc., can solve the problems of abnormal use, limited layout space, increased resistance loss, etc., to achieve Compact structure, high separation efficiency, reducing the effect of annular eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

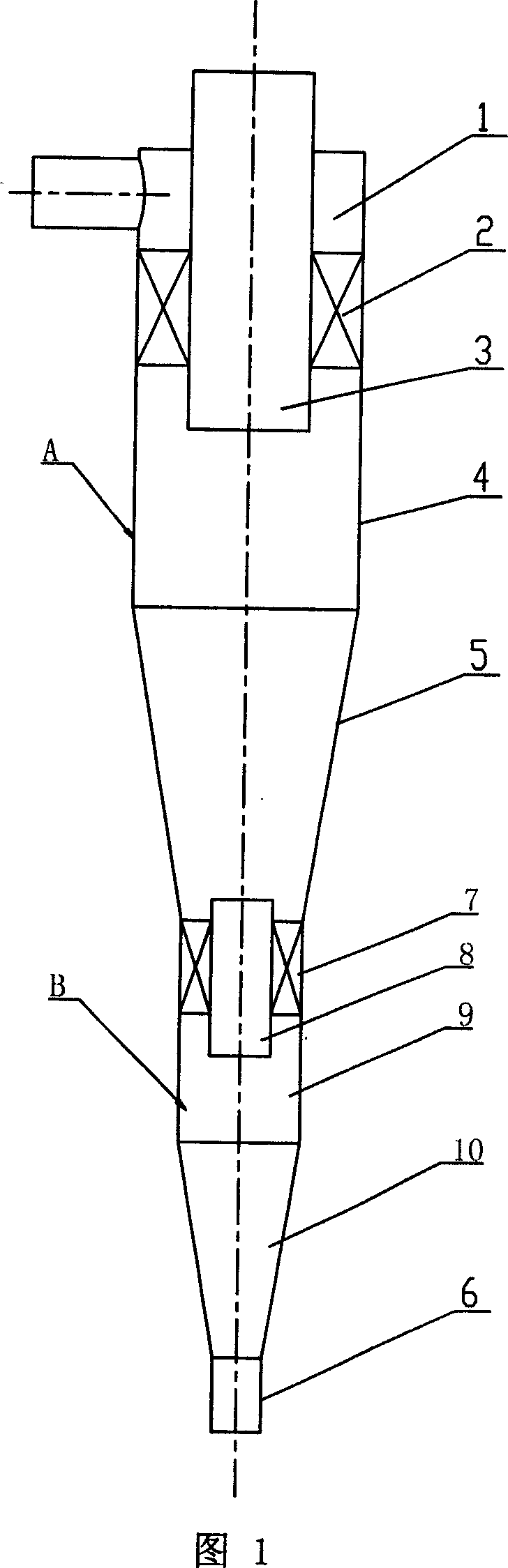

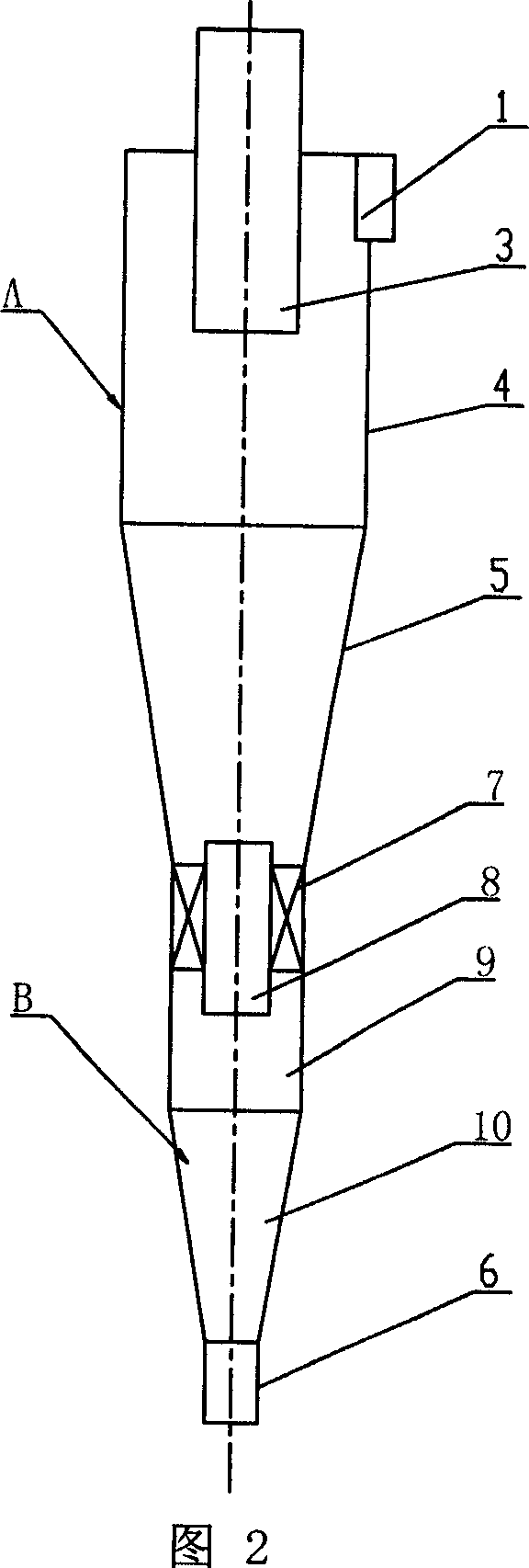

[0017] Referring to Figures 1 to 7, the present invention consists of a first-stage cyclone A and a second-stage cyclone B, and a second-stage cyclone is connected on the same axis as the lower end of the first-stage cyclone A. Device B. in:

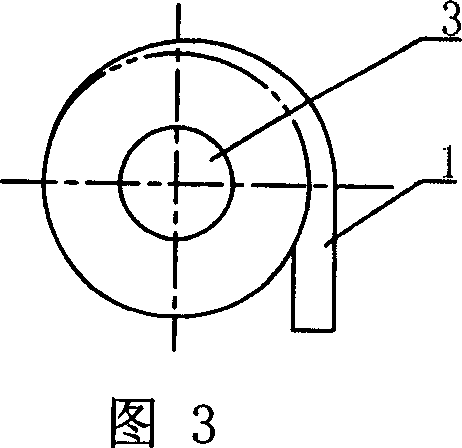

[0018] The first-stage cyclone A includes a feed chamber 1, an overflow pipe 3, a cylinder 4, and a cone 5. The feed chamber 1 is connected to the upper end of the cylinder 4, and the lower end of the cylinder 4 is connected to the upper end of the cone 5. The overflow pipe 3 coaxially penetrates the upper end of the feed chamber 1 into the barrel 4.

[0019] The second-stage cyclone B includes a secondary guide 7, a secondary overflow pipe 8, a secondary cylinder 9, a secondary cone 10 and a bottom flow pipe 6, and the upper end of the secondary cylinder 9 is connected to the first-stage cyclone The lower end of the cone 5 is connected with a small opening, the secondary guide 7 is installed in the upper end of the secondary cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com