Layout method of decomposing and grading system and corresponding water circulating system in aluminium plant

A circulating water system and grading system technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problem of increasing the laying length of circulating water system pipelines, plant land area and cooling water transmission energy, plant underground pipeline layout and construction difficulties and other problems, to achieve the effect of saving equipment investment costs, facilitating expansion, and reducing transportation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

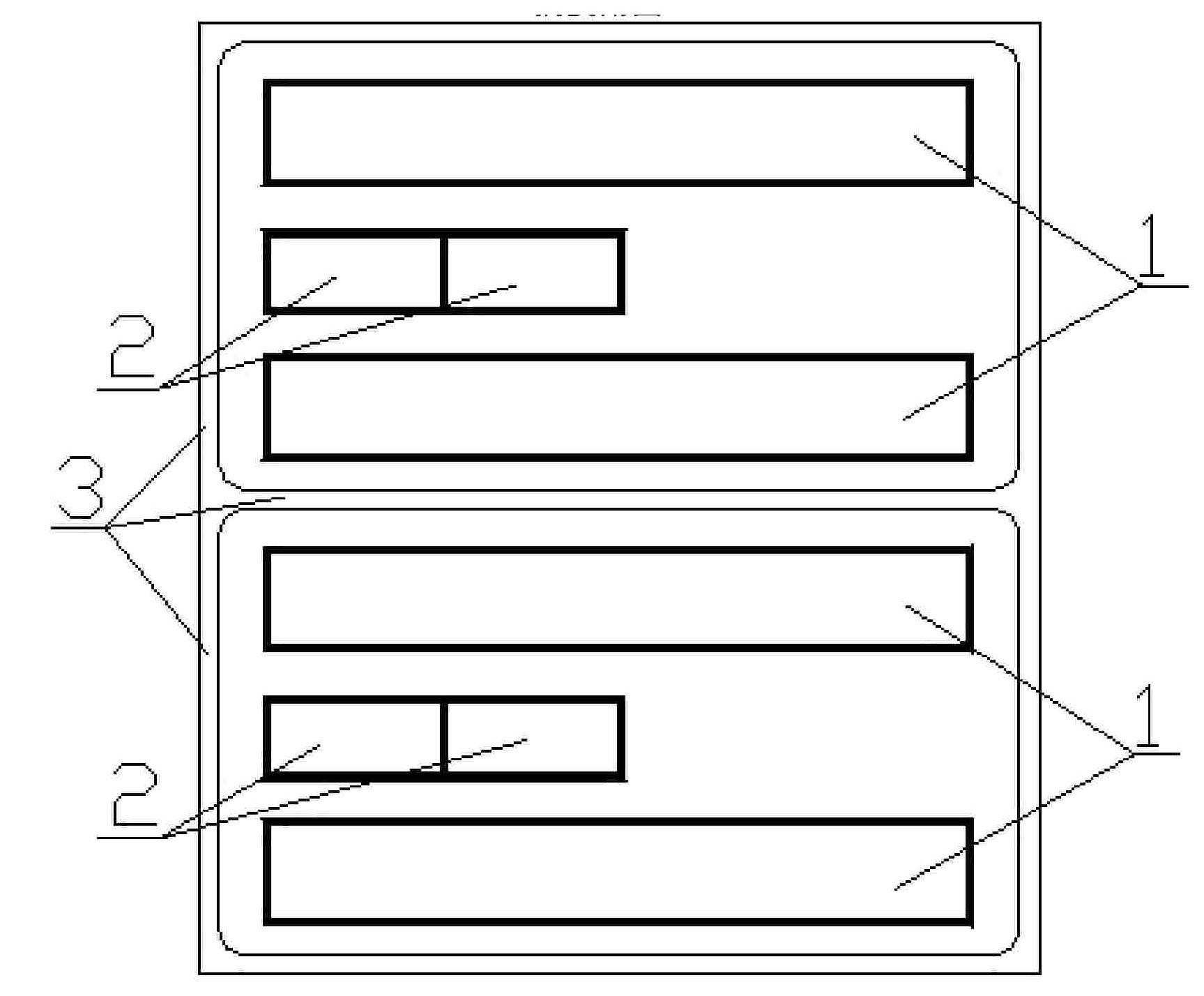

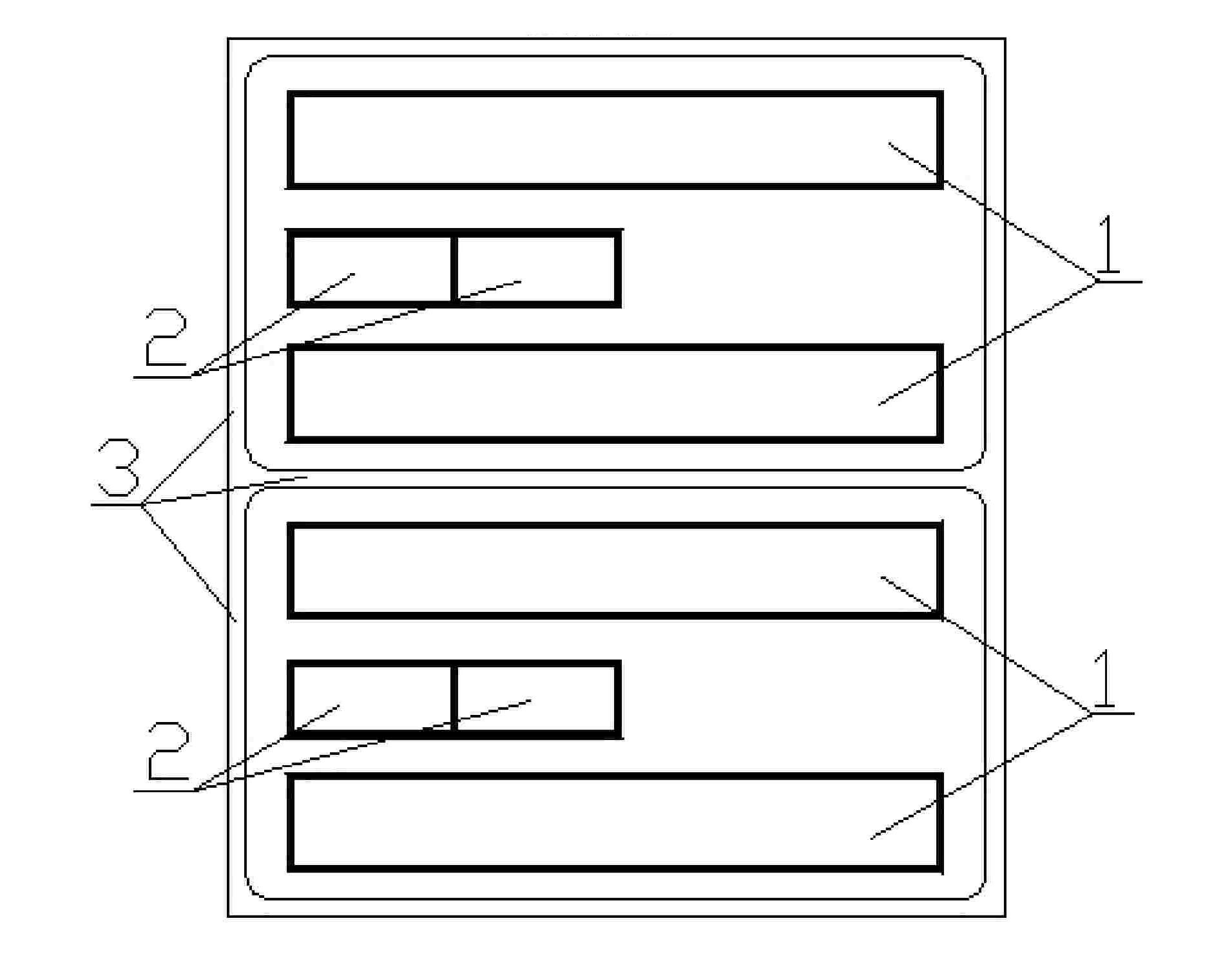

[0008] Embodiment: as shown in Fig. 1, it comprises decomposition classification system 1 and corresponding circulating water system 2, a group of decomposition classification system 1 that every group of circulation water system 2 all corresponds, in order to improve production capacity, save energy, and reduce The difficulty of construction in the factory area, the two sets of decomposition and grading systems 1 and the corresponding two sets of circulating water systems 2 are set in the same production area, and the corresponding two sets of circulating water systems 2 are in the middle of the two sets of decomposition and grading systems 1, which can be easily It is better to shorten the pipeline length between the decomposition and classification system 1 and the corresponding circulating water system 2, and at the same time set up the main road 3 in the factory area around the same production area with two sets of decomposition and classification systems 1 and two groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com