Underground coal preparation technology adopting aqueous medium

A water medium and process technology, which is applied in the field of water medium underground coal preparation, can solve the problems of increasing the process of heavy medium preparation and recovery, difficulty in guaranteeing the separation effect of fine-grained materials, and high energy consumption of dry coal preparation equipment. , to achieve the effect of improving the downhole production environment, high sorting accuracy and reliability, and reducing surface environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

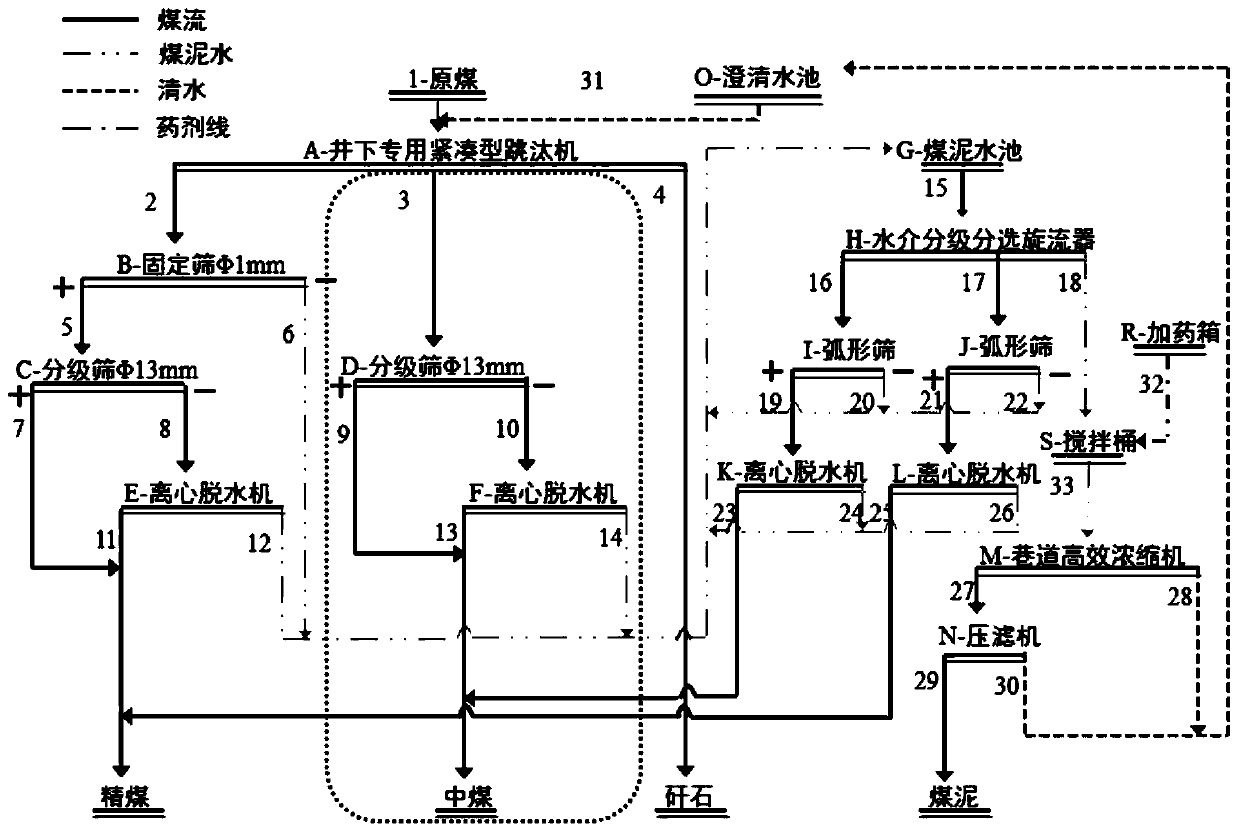

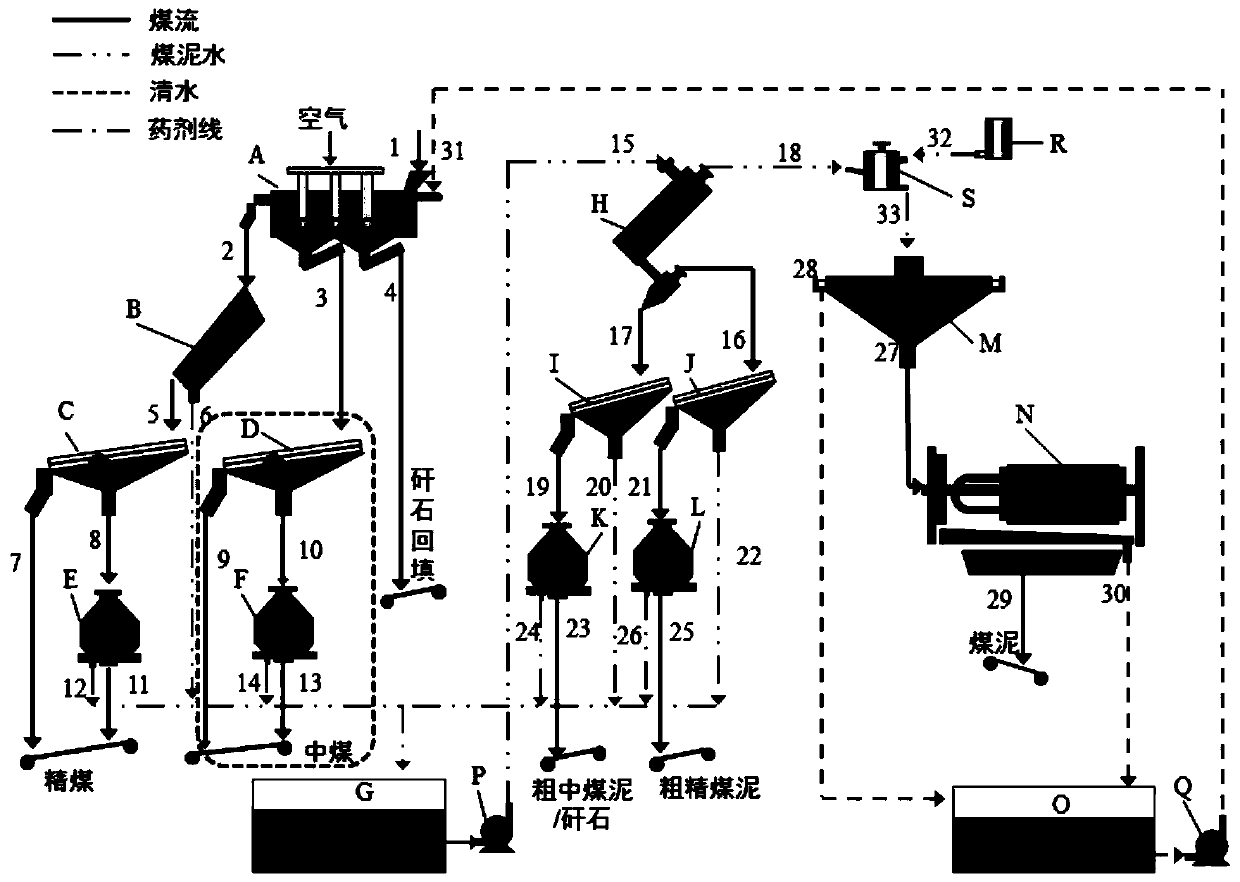

[0028] Attached below figure 2 The specific embodiment of the present invention is further described:

[0029] Such as figure 1 and figure 2 Shown, the water medium underground coal preparation process of the present invention is characterized in that the steps are as follows:

[0030] The mined raw coal 1 is directly sent to the underground special compact jig A for sorting without going into the well, and the overflow clean coal 2, jigged medium coal 3 and jigging gangue 4 are obtained by sorting, and the jigging gangue 4 is used in the underground filling;

[0031] The overflow clean coal 2 is fed into the φ1mm fixed sieve B for pre-dehydration. After dehydration, the over-sieve clean coal 5 and the under-sieve water 6 containing clean coal with a particle size less than 1mm discharged from the under-sieve are fed into the coal slime pool G, and the over-sieve clean coal 5 Feed into φ13mm grading sieve C for sorting to obtain lump clean coal 7 with a particle size gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com