Lower-drive type revolving working-table intermittent mechanism

A rotary table and transmission technology, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of high power consumption, high manufacturing cost, and small workbench space, so as to increase space and manufacture The process is simple and the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

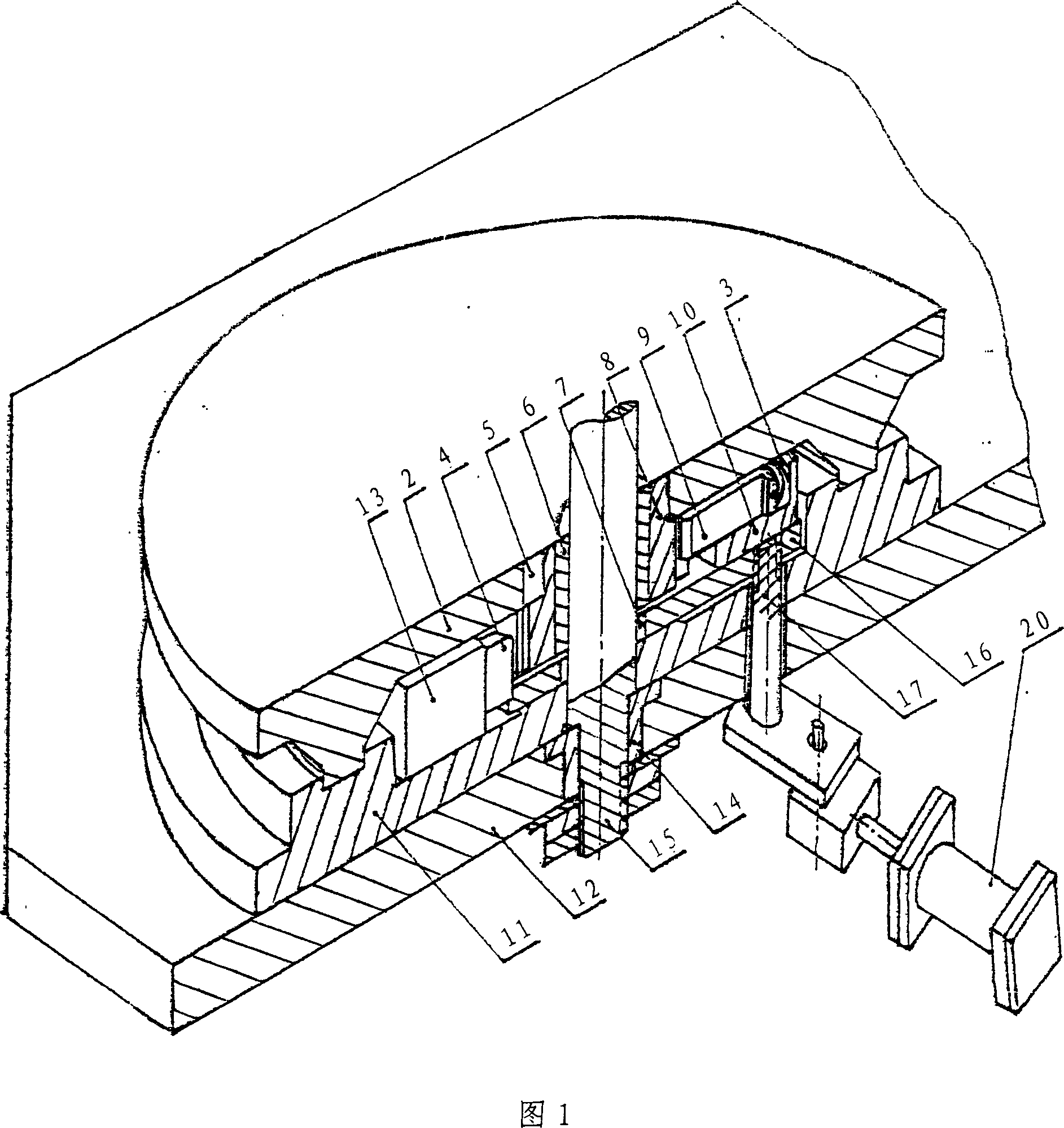

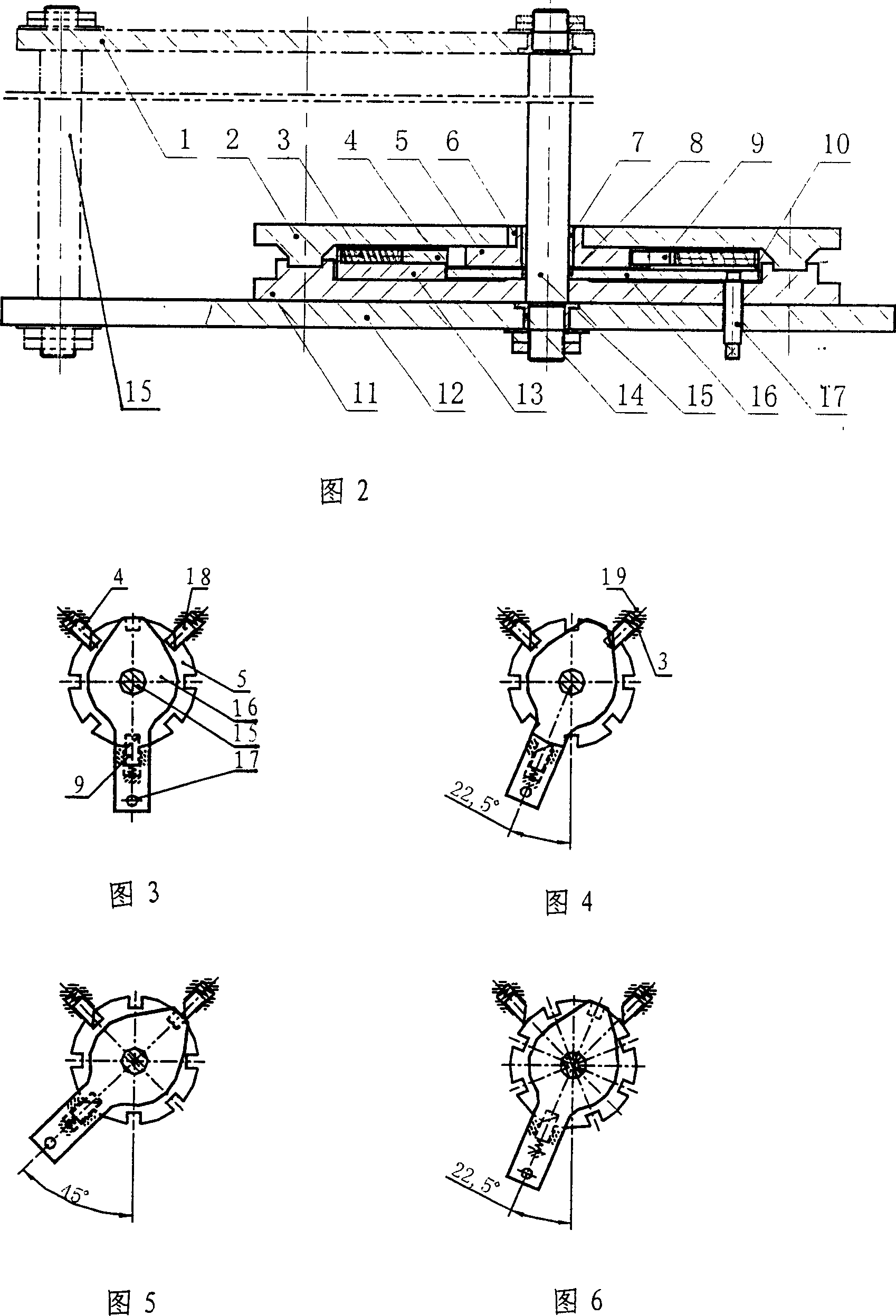

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] With reference to accompanying drawing 1-6, with the rotary table 2 of ductile iron material, special heat treatment system processing and high-alloy steel material, the ratchet wheel 5 of special heat treatment system processing is connected as a rigid body by key 6 and cover I7; Ratchet wheel 5 is provided with The indexing groove that controls the action of the driving rotation mechanism and the two sets of positioning mechanisms, the driving pawl fixing seat 10 and the deflection driving lever 17 are respectively connected to the upper and lower cam body remote rods 16, they can rotate around the shaft 15, and the positioning pawl is fixed The seat I13 and the positioning ratchet fixing seat II19 are fixed on the pede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com