Steel-wire isolator

A technology of steel wire rope and vibration isolator, which is applied in the field of anti-shock vibration isolator, which can solve the problems of no balance of lateral load, insufficient damping and vibration isolation performance, and limitation of coil spring vibration isolator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

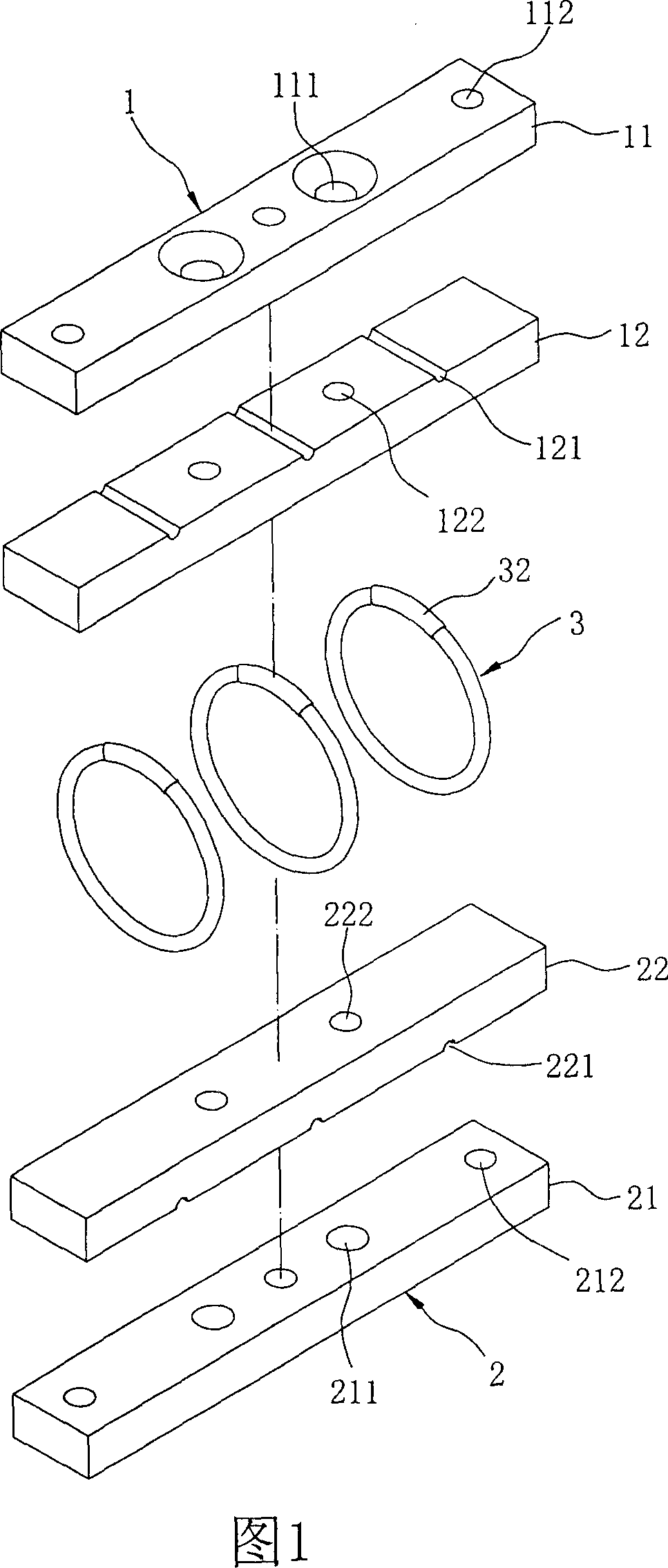

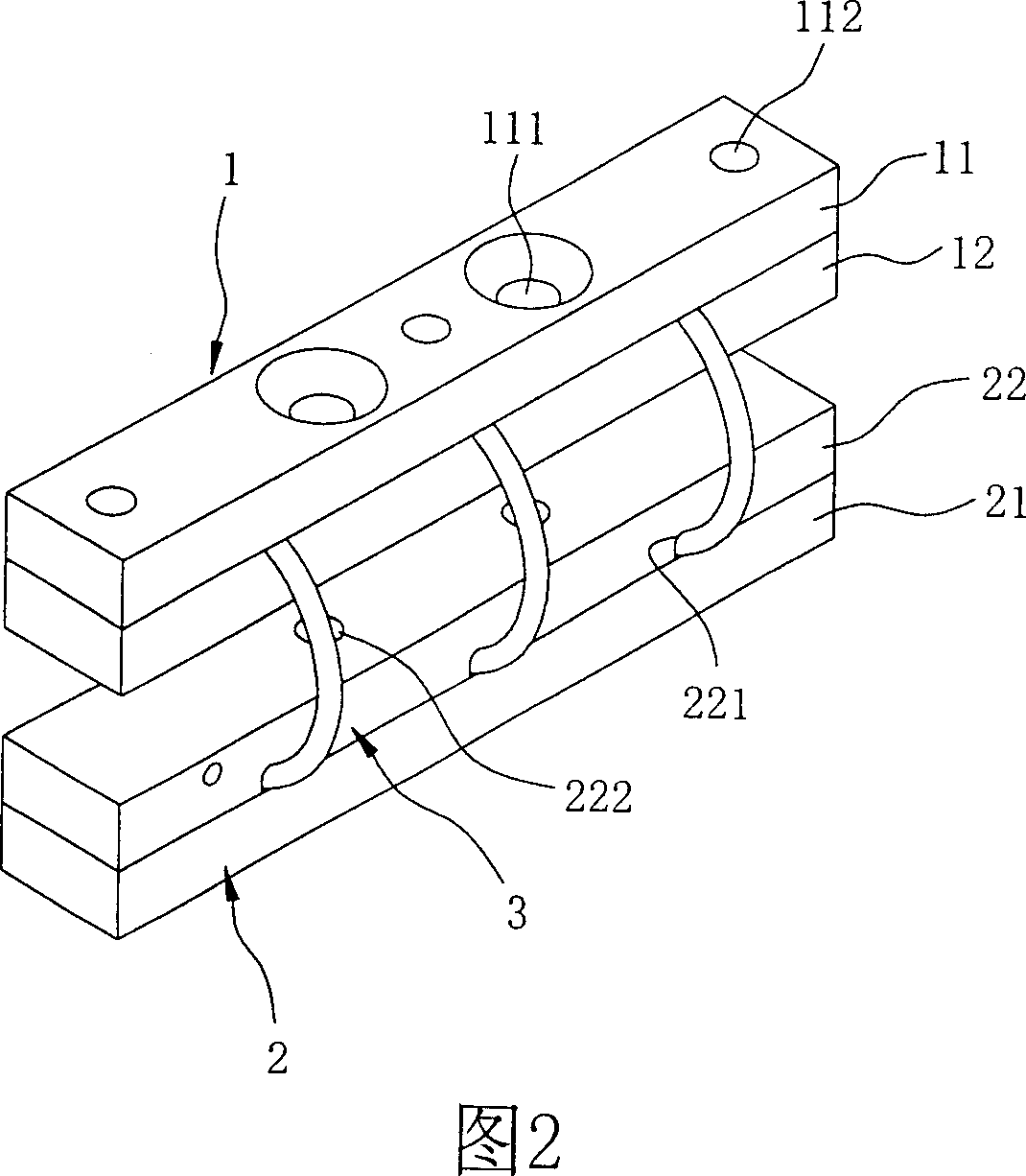

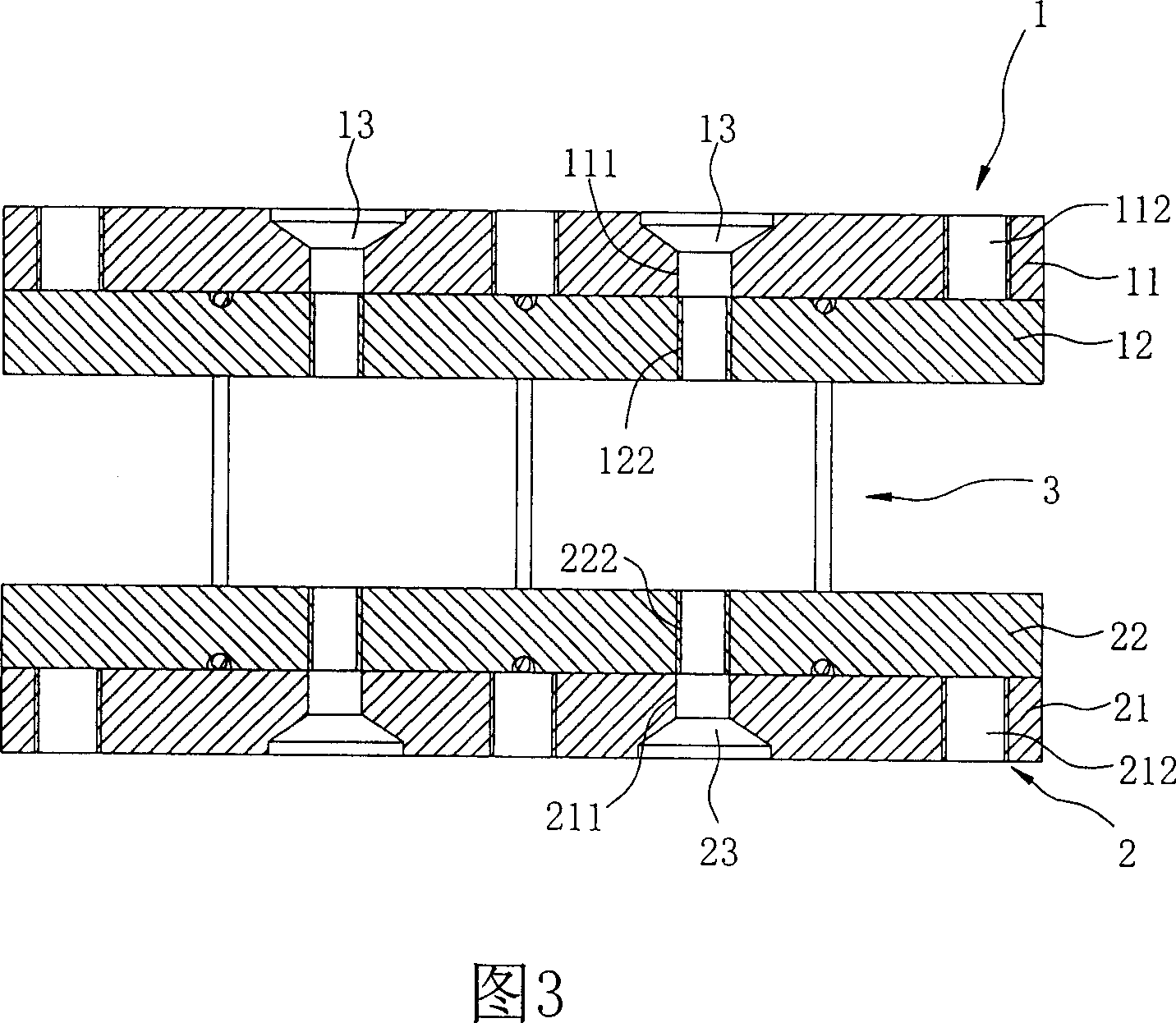

[0050] Please refer to Fig. 1 to Fig. 4, the present invention provides a kind of steel wire rope vibration isolator, discloses a kind of annular type steel wire rope vibration isolator in this embodiment, it comprises a first fixing base 1, a second fixing base 2 and multiple A steel wire rope 3 wound between the first and second fixing bases 1 and 2, the first fixing base 1 includes a first clamping plate 11 and a second clamping plate 12, the first clamping plate 11 and the second clamping plate 12 The second clamping plate 12 is an elongated plate body facing up and down, but its shape is not limited thereto. The side of the second clamping plate 12 adjacent to the first clamping plate 11 is provided with a plurality of semicircular grooves 121 corresponding to the steel wire ropes 3 at intervals, and the semicircular grooves 121 can accommodate these steel wire ropes 3, increasing the circular The contact area of the steel wire rope 3 when the first clamping plate 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com