Capacitor structure

A capacitor structure, capacitor technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of increasing the electrode surface area, difficult to control the uniformity and stability of the dielectric film layer, complicated processes, etc., and achieve the capacitance value per unit area. Improve and avoid the effects of capacitor matching and poor yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

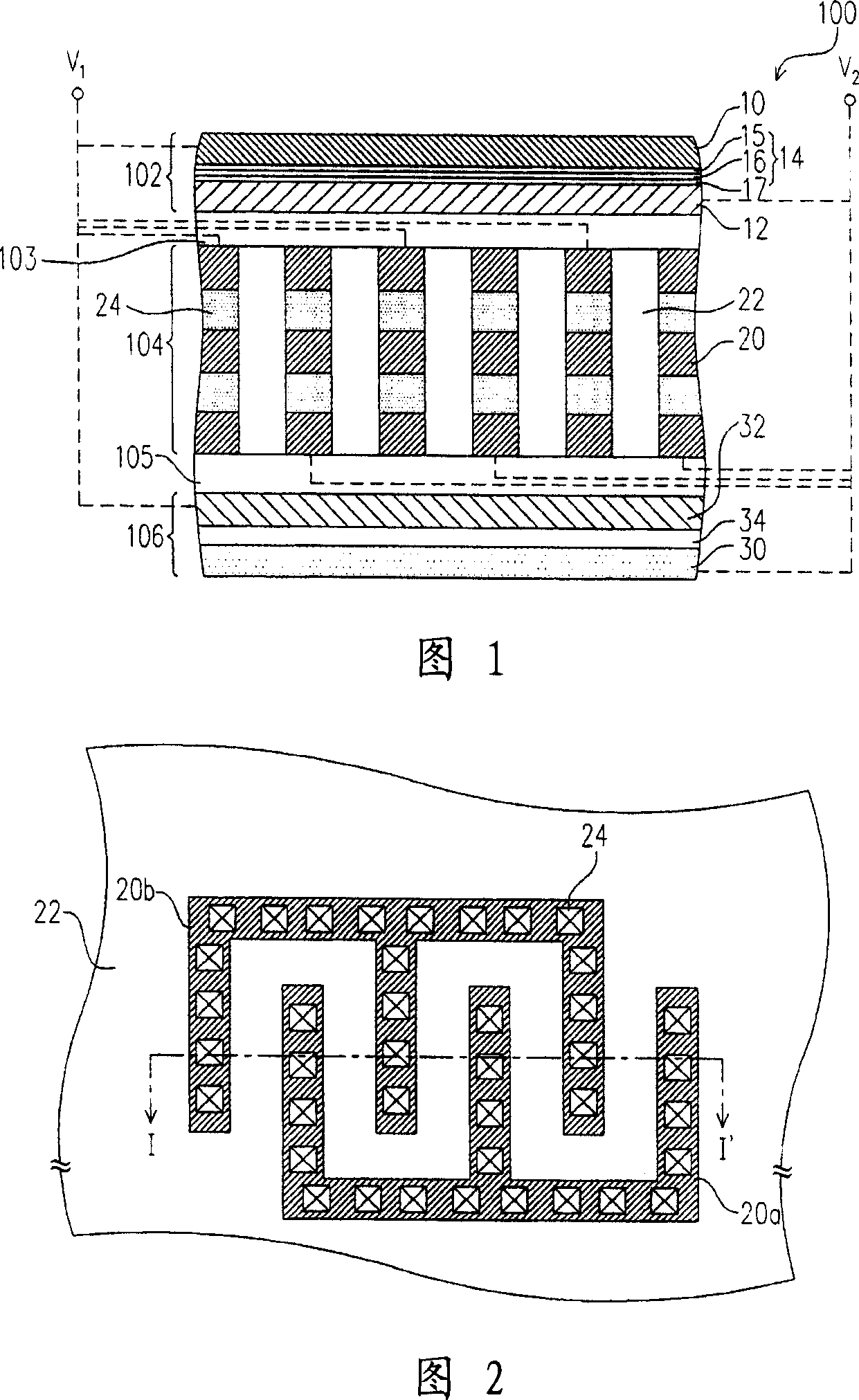

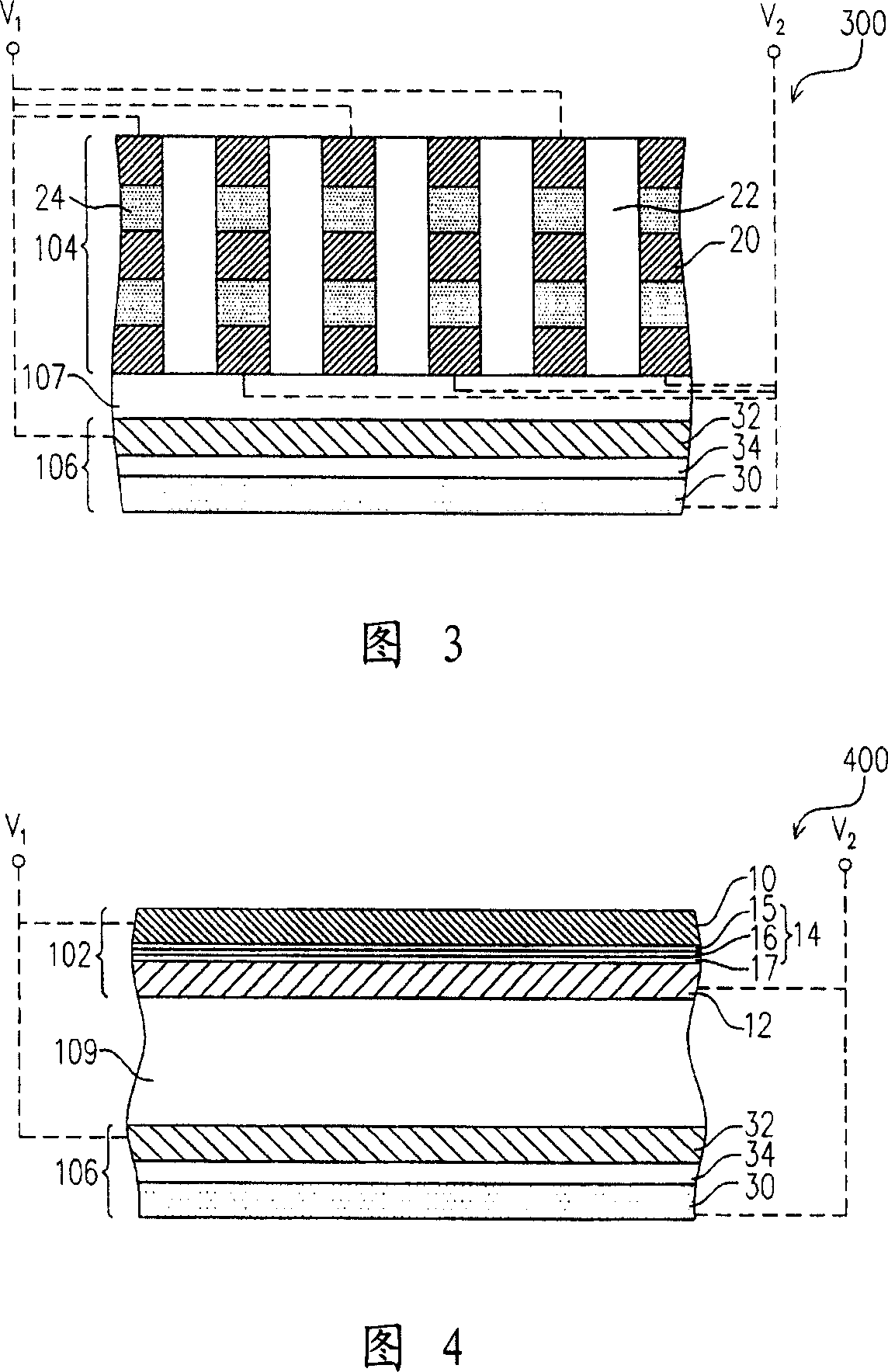

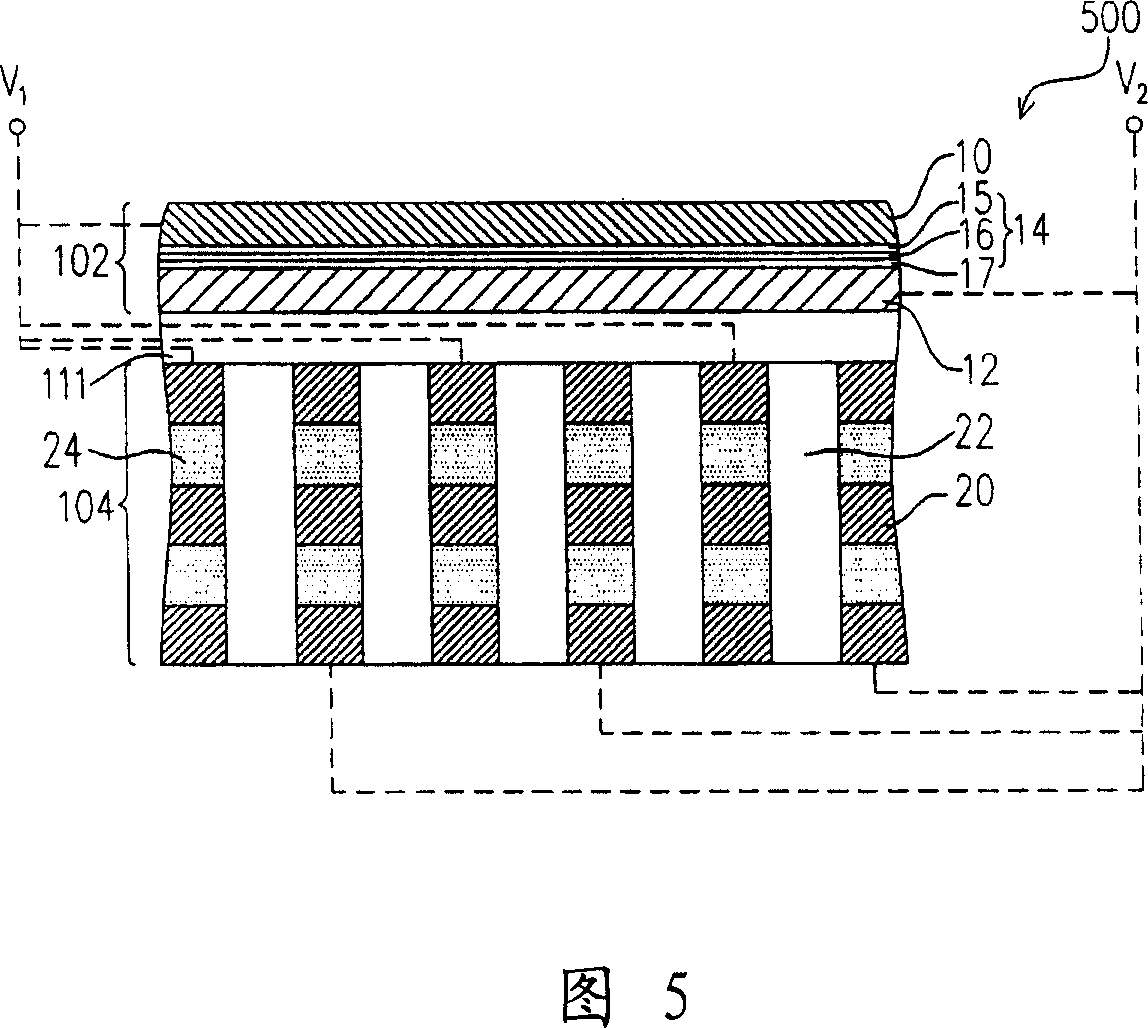

[0042] FIG. 1 is a schematic cross-sectional view of a capacitor structure according to an embodiment of the present invention. Fig. 2 is a top view of the capacitor 104 in the capacitance structure in Fig. 1, and its I-I' section is corresponding to Fig. 1 . Referring to FIG. 1 , the capacitor structure 100 is composed of a metal-insulator-metal capacitor 102 , a metal-wire capacitor 104 and a metal-insulator-polysilicon capacitor 106 connected in parallel. The capacitor 102 includes electrodes 10 , 12 and an insulating layer 14 , wherein the electrode 12 is disposed below the electrode 10 , and the insulating layer 14 is disposed between the electrodes 10 and 12 . The materials of the electrodes 10 and 12 are, for example, metal or other existing conductive materials suitable as electrodes. The insulating layer 14 is, for example, a composite dielectric layer composed of a silicon oxide layer 15 , a silicon nitride layer 16 and another silicon oxide layer 17 . In another e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com