A kind of Fe-doped iron oxide large-area capacitance material, high energy density and power density capacitor and its preparation method and application

A large-area, iron oxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited area power density, low conductivity, etc., and achieve easy promotion, high power density, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention further discloses a method for preparing the above-mentioned symmetrical electrochemical capacitor, which includes the following steps:

[0031] Step a) Prepare the electrode material as CC@Fe 2 o 3 -F;

[0032] Step b) Assembling positive and negative electrodes: two pieces of electrode material CC@Fe 2 o 3The middle of -F is separated by a diaphragm, the electrolyte is injected, and a current collector is added to the outside of the positive and negative materials to obtain a symmetrical electrochemical capacitor. In order to further increase the energy density of the symmetrical electrochemical capacitor, the concentration of the KOH solution is preferably 4-6 mol / L.

Embodiment 1

[0037] 1. Preparation of electrode materials:

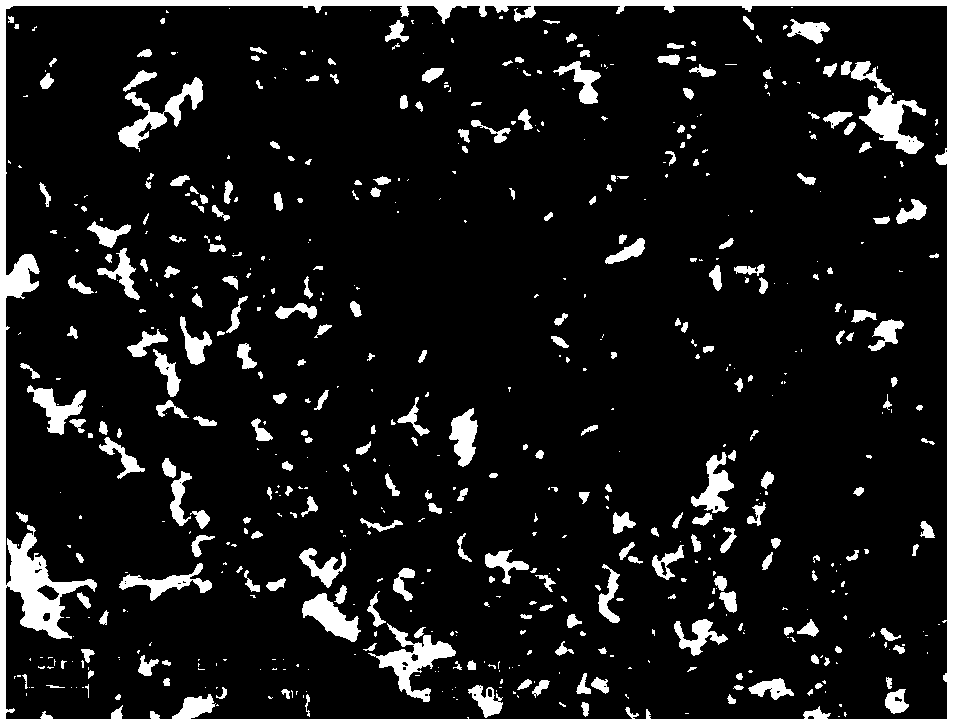

[0038] At room temperature, weigh 2.0mmol Fe(NO 3 ) 3 9H 2 O, a certain amount of NH 4 F and 5.0mmol urea, add 17.5mL H 2 O with 17.5 mL ethanol to dissolve. A piece of carbon cloth (2 cm x 1.5 cm) was then placed into the solution after sonication in deionized water and ethanol for 20 min. After soaking the carbon cloth for 30 minutes, the solution was transferred to a 50 mL Teflon-lined stainless steel autoclave. Next, the kettle was sealed and heated to 120° C. in an electric oven. After heating for 6 hours, the product was washed several times with water and ethanol, then vacuum-dried at 60°C for 3 hours, and finally pyrolyzed in air (2°C / min to 400°C and held for 2 hours).

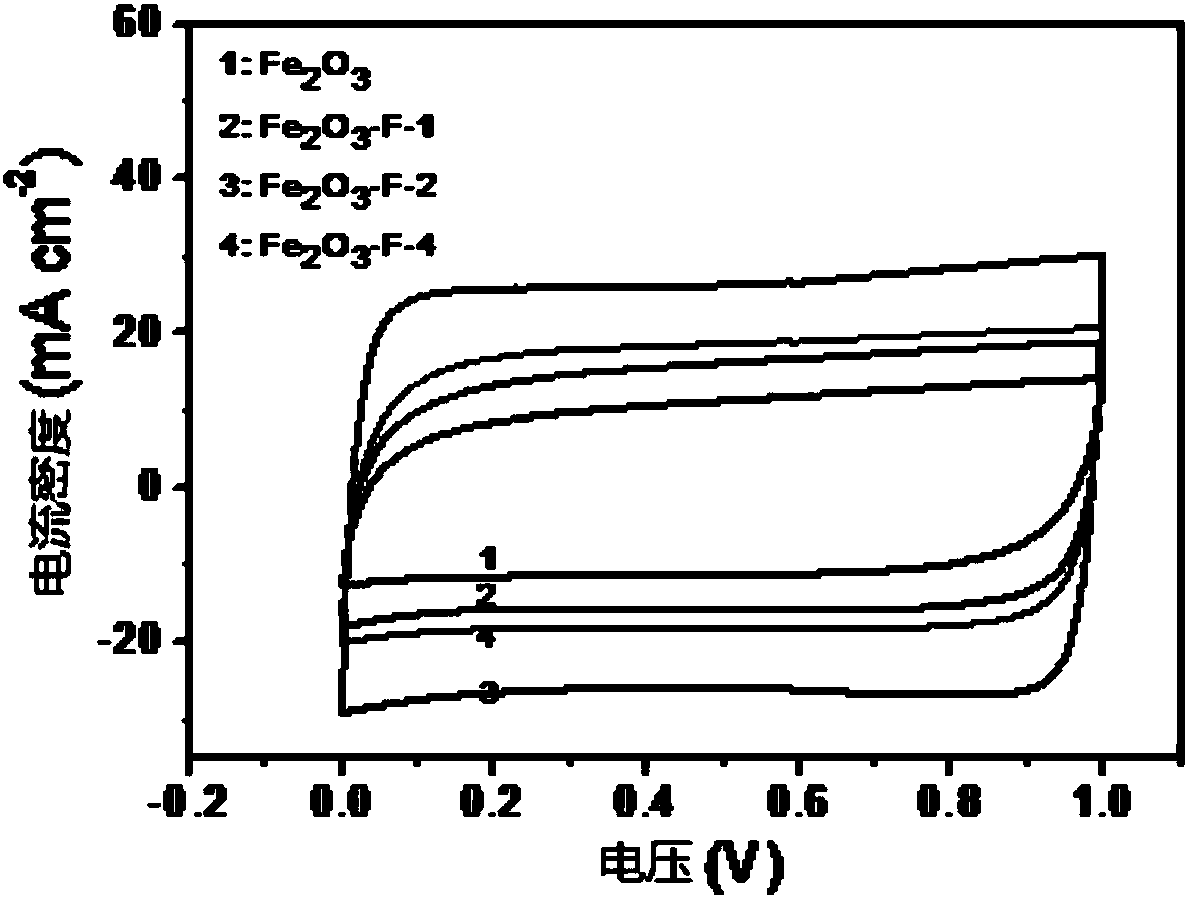

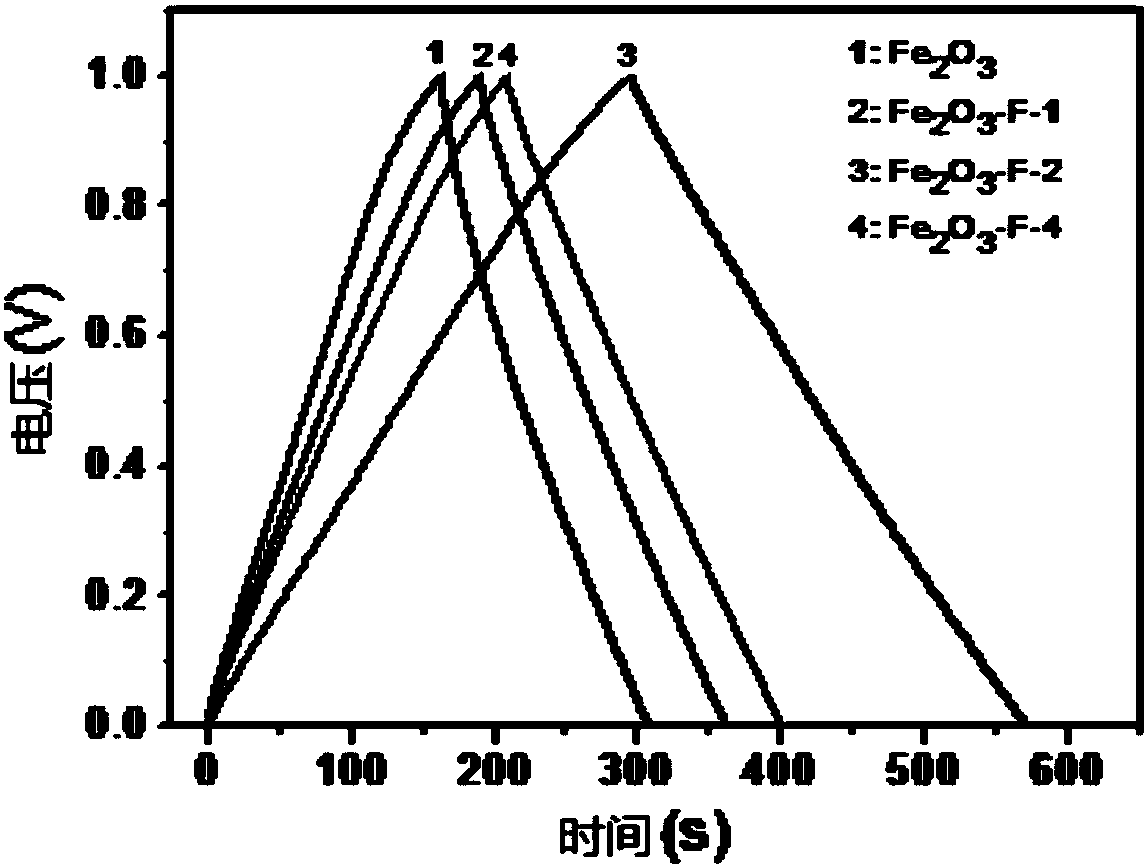

[0039] NH 4 The addition amount of F is respectively 1, 2, 4mmol, and another comparison: with 2mmol NH 4 Cl instead of 2 mmol NH 4 The comparison of F without doping with fluorine.

[0040] The above parts are recorded as CC@Fe in turn 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com