Semiconductor laser device and method for manufacturing the same

A technology of laser components and manufacturing methods, which can be applied to semiconductor lasers, laser components, structures of optical waveguide semiconductors, etc., and can solve problems such as refractive index difference, low resistance, and reliability reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

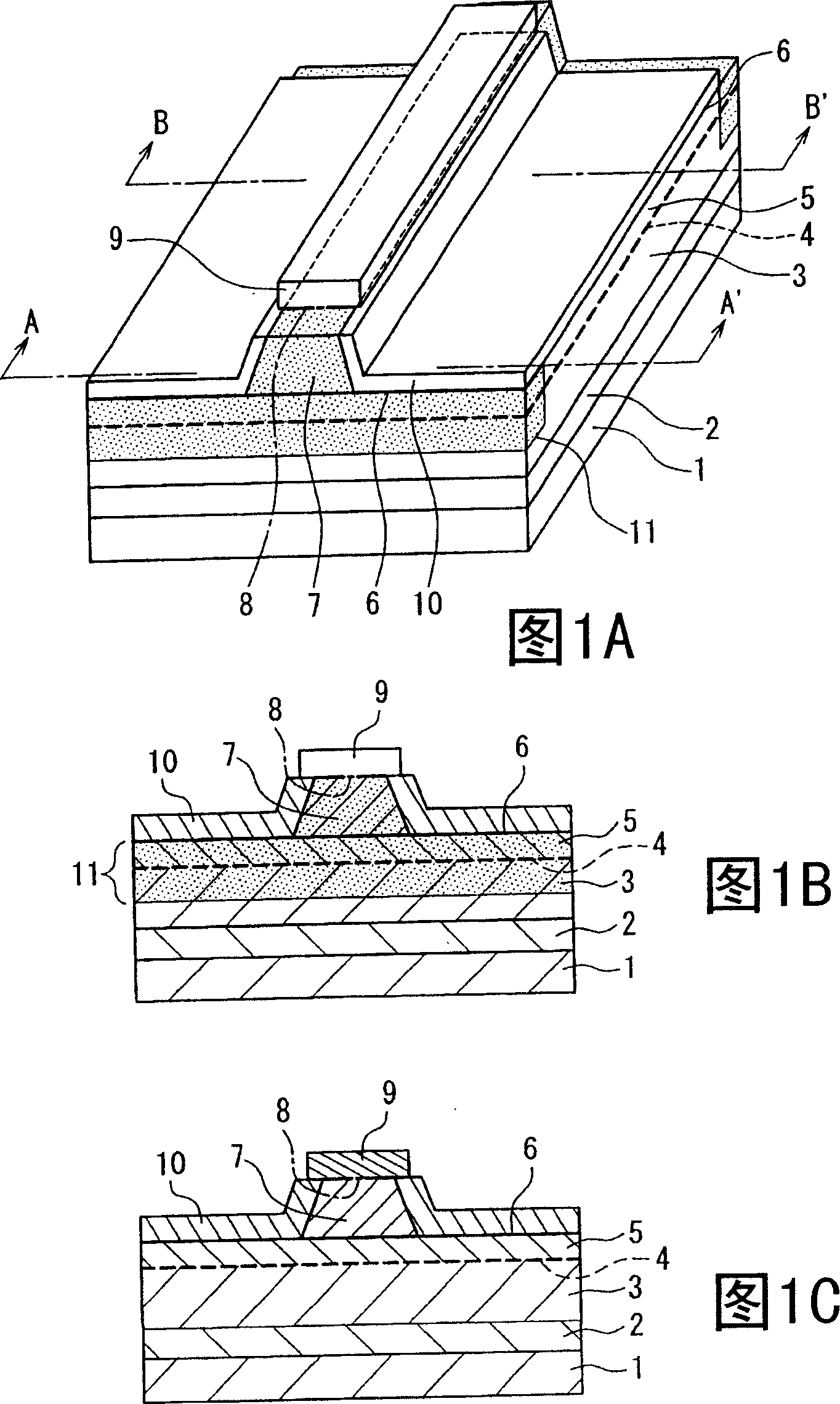

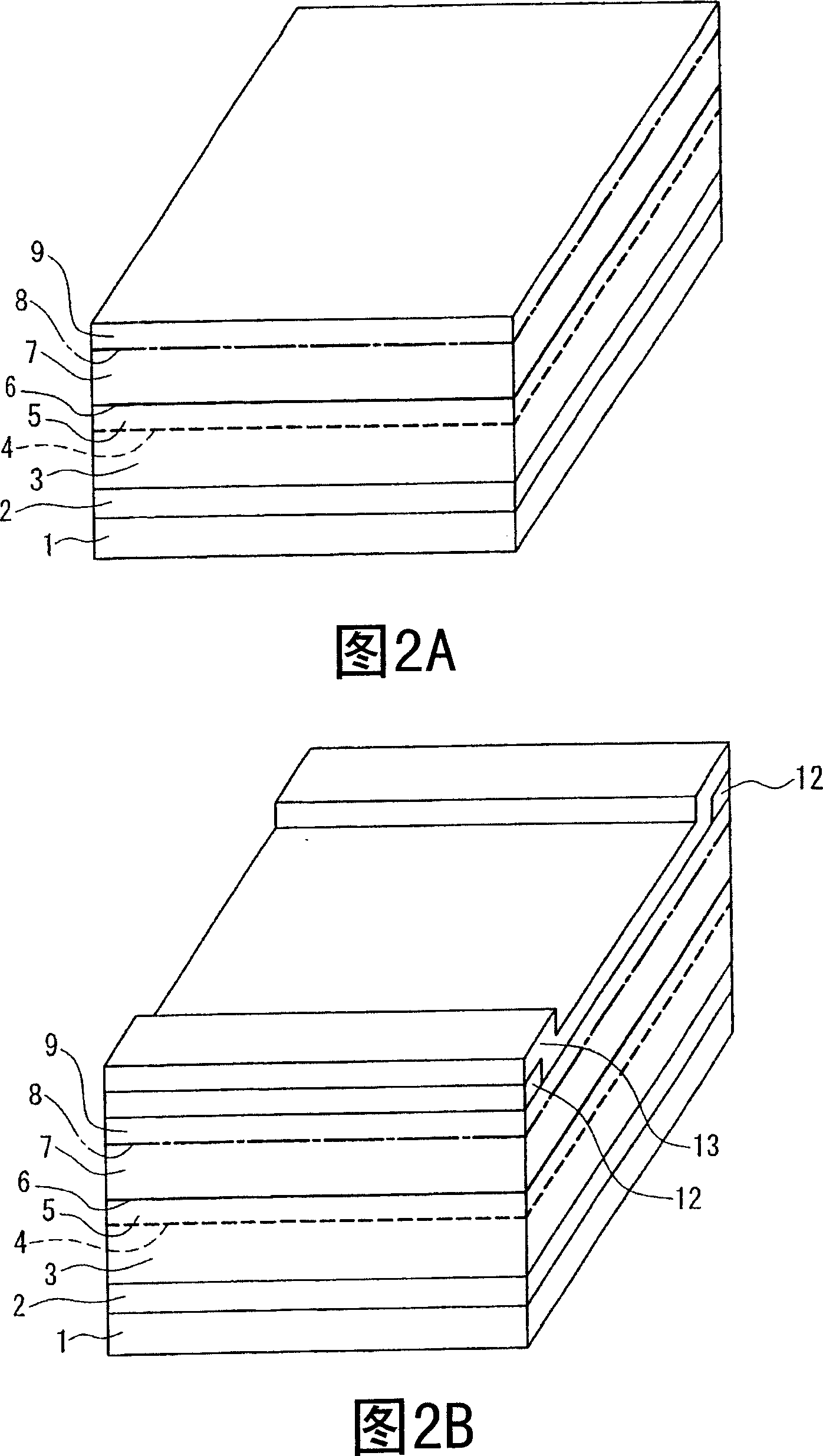

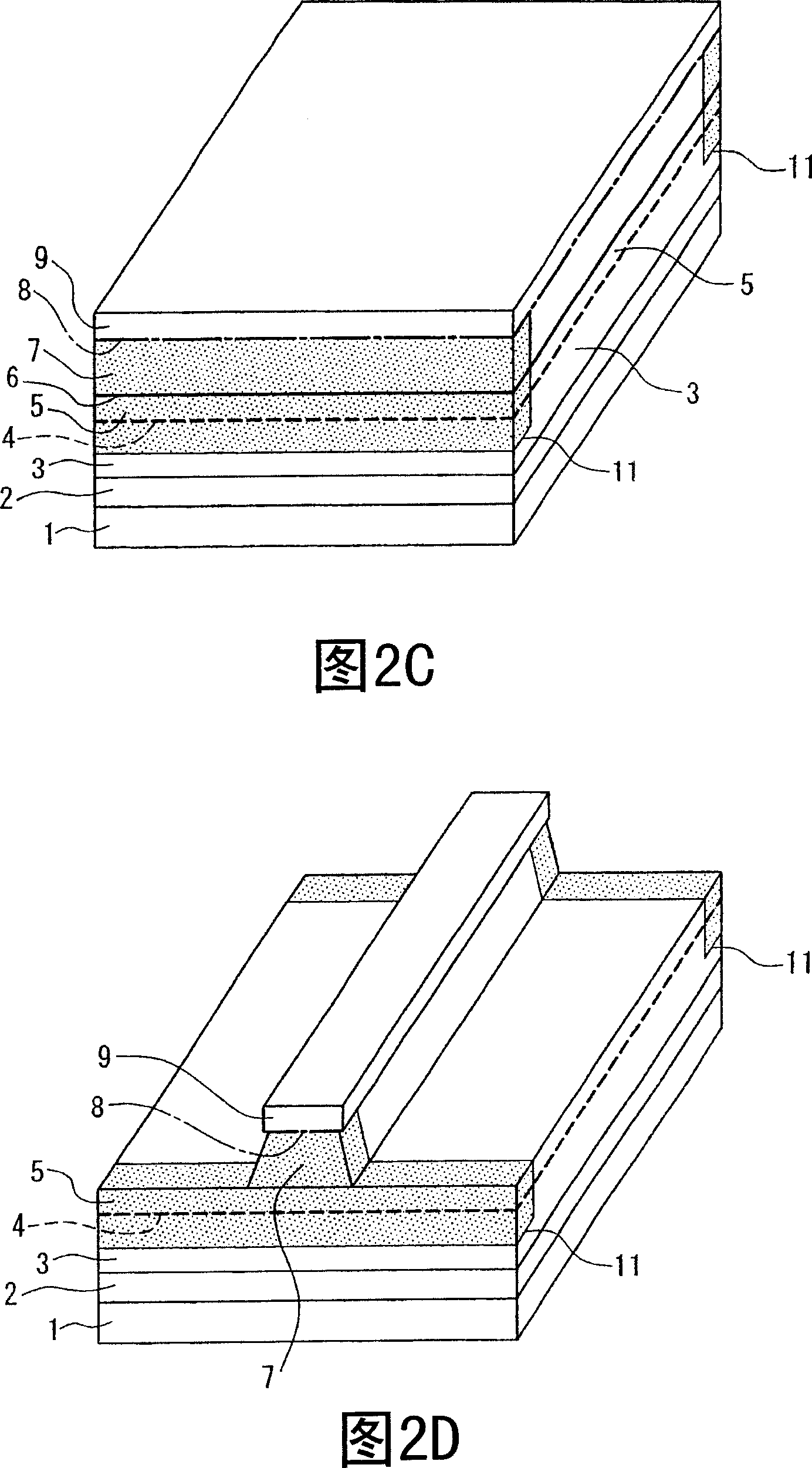

[0033] The semiconductor laser device of the present invention includes a cladding layer of the first conductivity type, an active layer having a multiple quantum well structure, a stacked structure of the first cladding layer of the second conductivity type, and a second conductivity type forming a ridge-shaped waveguide. The second cladding layer, the contact layer of the second conductivity type on the second cladding layer; and an end face window structure is provided, and impurities diffuse into the active layer region of the end face in the direction of the resonator, so as to be compatible with the end face Compared with the gain region of the other parts, the energy band gap is enlarged. Then, in the cladding layer of the second conductivity type, the impurity concentration in the gain region is adjusted to be equal to or greater than the impurity concentration in the region of the end face window structure, therefore, the gain portion and the end face window structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com