Paste coater and PoP automatic mounting apparatus employing the same

A technology of automatic installation and paste coating machine, which can be used in devices for coating liquid on surfaces, welding equipment, metal processing equipment, etc., and can solve the problem of not being able to optimally adjust the gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

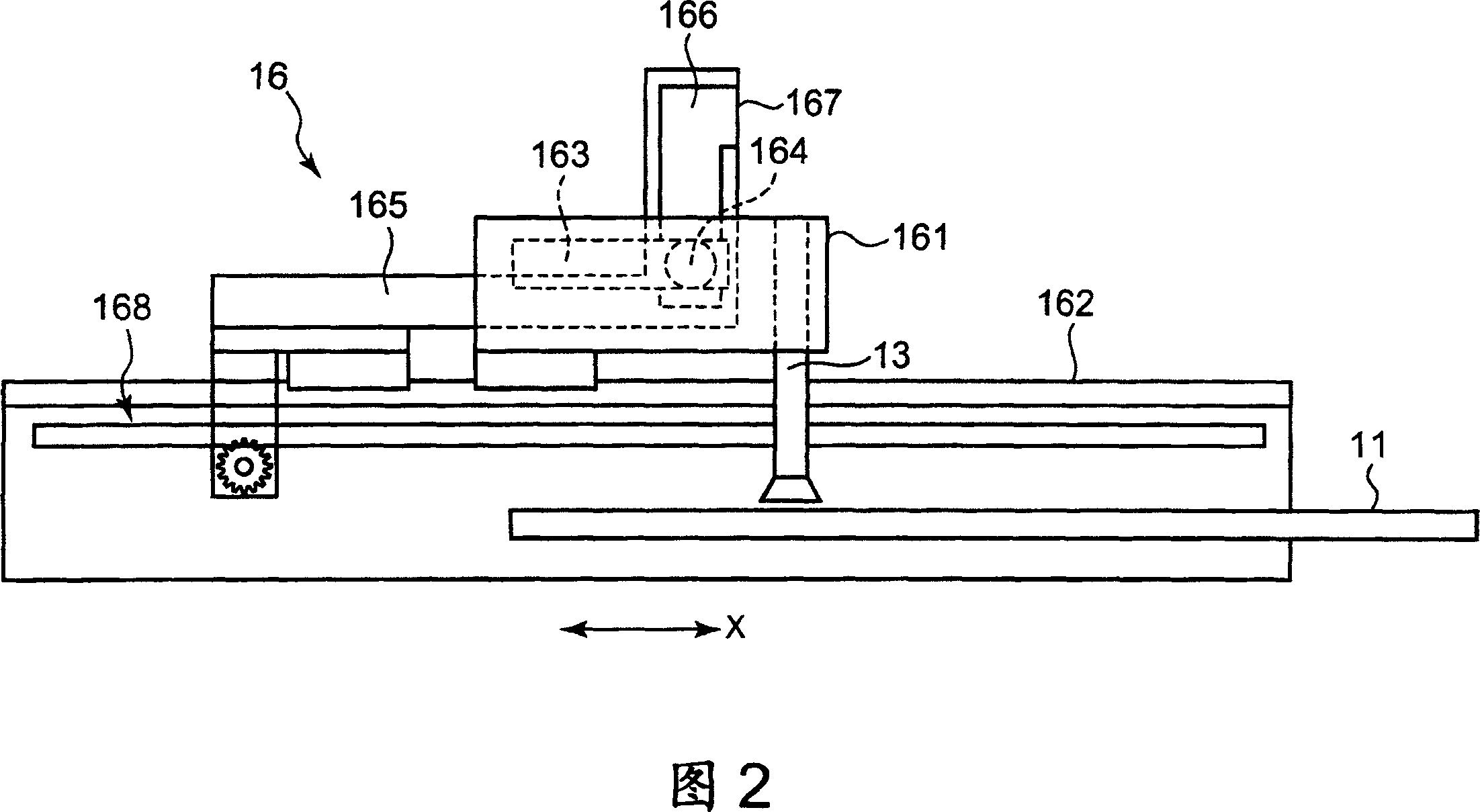

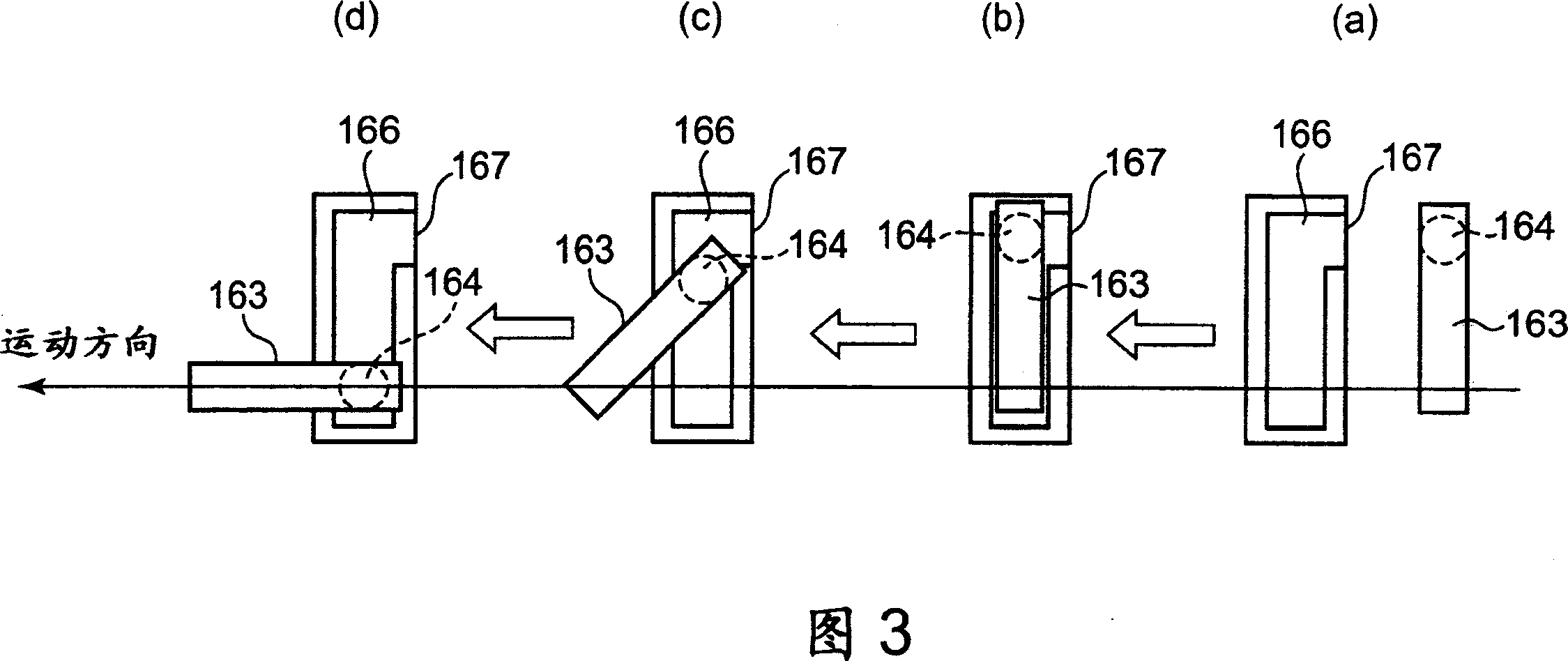

[0064] Preferred embodiments of the present invention will be described in detail below while referring to the accompanying drawings. The same reference numerals are used to denote the same or corresponding parts, and explanation thereof will not be repeated.

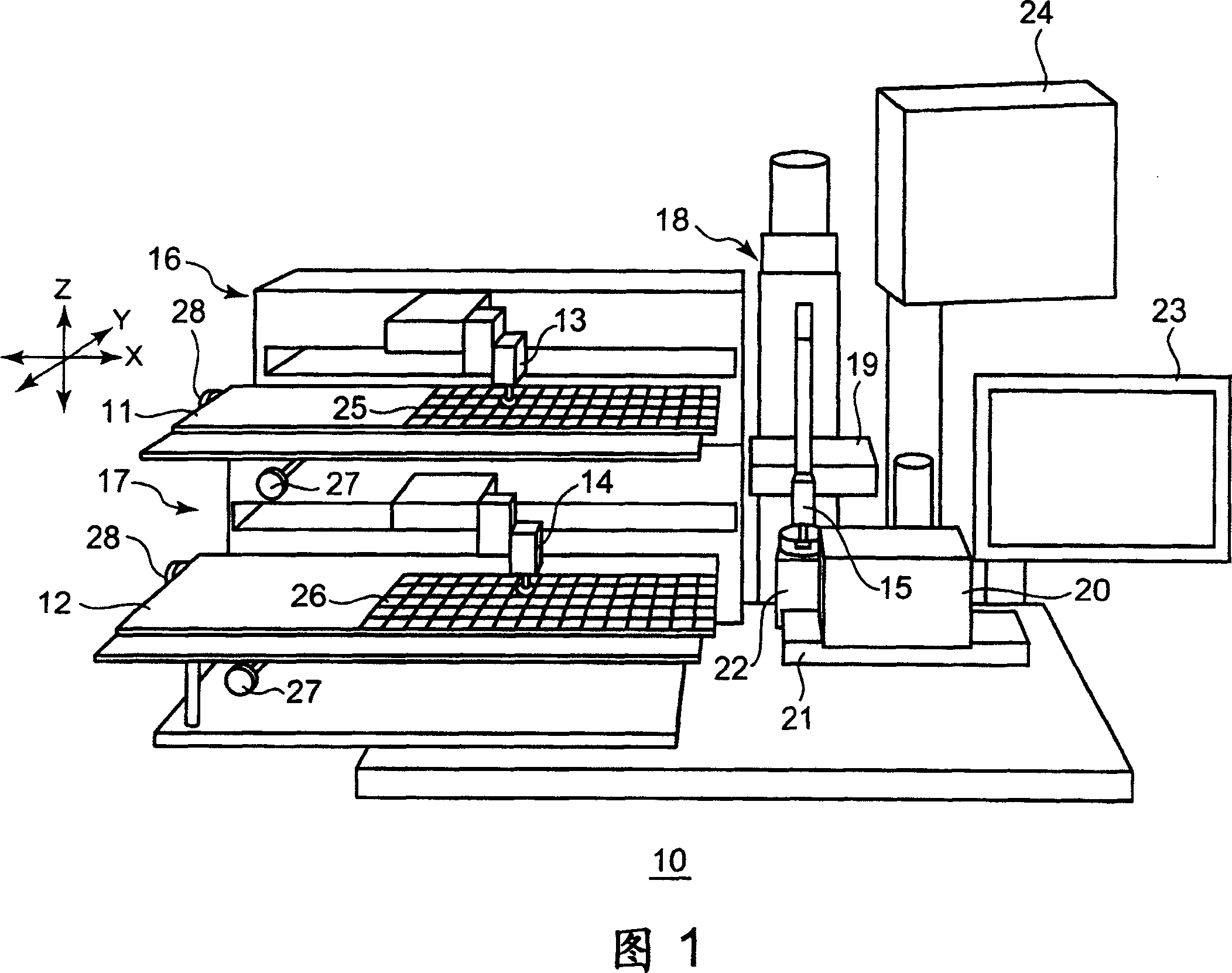

[0065] PoP automatic installation equipment

[0066]Referring to Fig. 1, the PoP automatic mounting equipment 10 according to this embodiment assembles a semiconductor package, such as BGA, CSP or flip chip, on top of another semiconductor package, and includes: an upper tray 11, a lower tray 12, a suction nozzle 13 to 15. Nozzle conveying mechanism 16 to 18, position correction unit 19, pasting machine (including sliding mechanism) 20, inverted extraction unit 21, position lighting and vertical identical observation camera optical system 22, alignment color monitor 23 and controller 24 .

[0067] A plurality of upper semiconductor packages 25 are arranged on the upper tray 11 , and a plurality of lower semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com