Nano film plating process and machine for glazed ceramic tile

A technology of nano-film and ceramic glaze, which is applied in the field of ceramic glazed tiles, can solve the problems that cannot be adopted, the quality of coating film is difficult to guarantee, and the uniformity of coating film thickness is not easy to control, etc., and achieve the effect of convenient and accurate operation, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

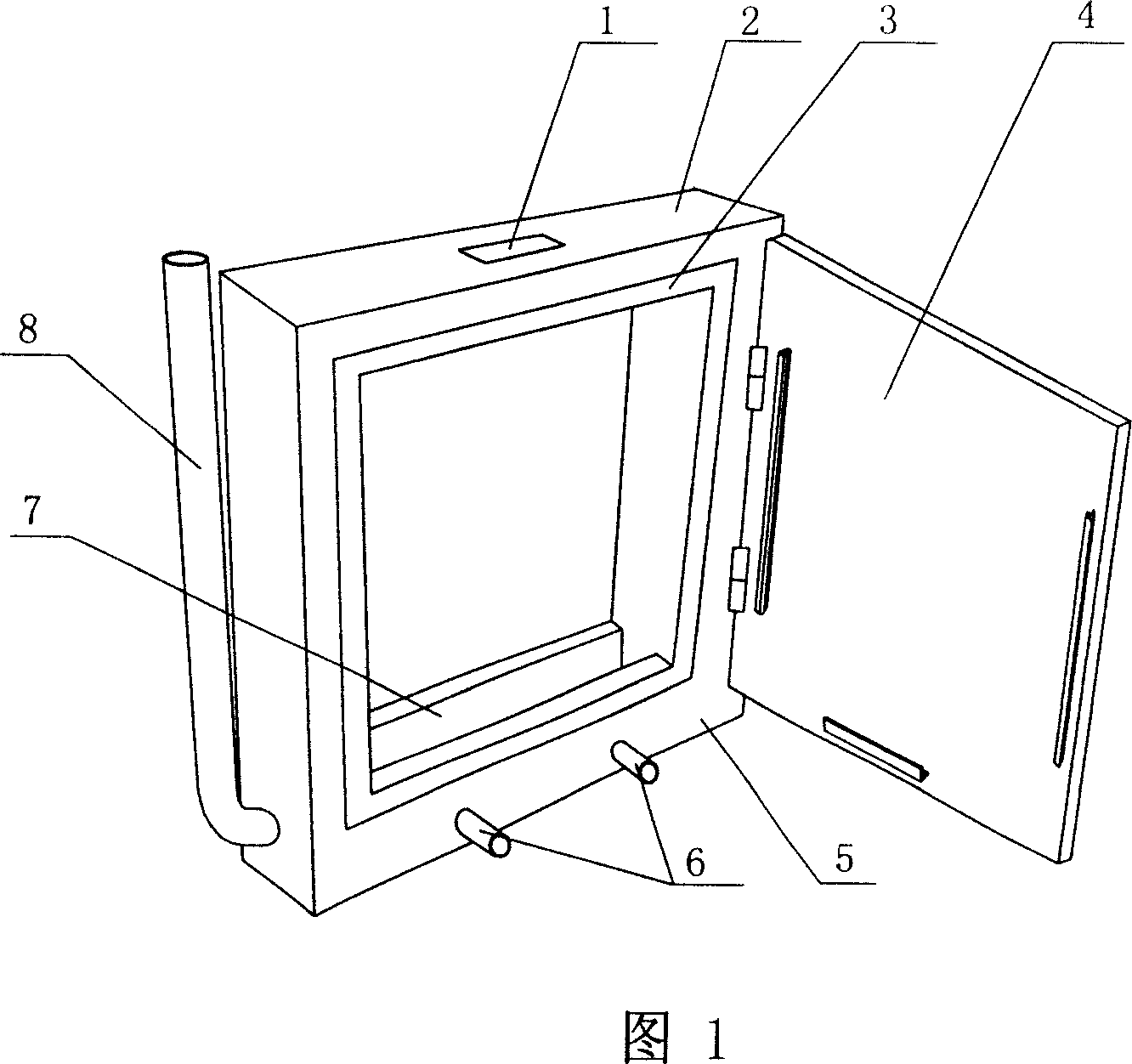

[0020] As shown in the figure, the nano film coating machine of the present invention has a sol immersion tank 7 composed of frames 2, 5, etc. and a sealed door 4, and the sealed door has a pair opposite, fixed on the frame with a hinge, sealed The inner side of the door 4 is provided with ceramic glazed brick fixing slots, the lower frame 5 of the frame is provided with a sol inlet and outlet 6, the upper frame 2 of the frame is provided with a vent 1, and the frame is fixed with a sealing ring 3, and the sol dipping tank The bottom of 7 is connected with simple and easy transparent tube liquid level gauge 8.

[0021] Operation process 1:

[0022] Using butyl titanate as raw material, ethanol EtOH as solvent, according to Ti(OBu) 4 :EtOH:H 2 O: HNO 3 A stable sol was prepared at a molar ratio of acetylacetone AcAc=1:18:2:0.2:0.5, where...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap