Electronic turning warning squealer-flash for automobile

A technology for automotive electronics and flashers, which is applied in the directions of sound signal devices, optical signals, vehicle components, etc., can solve the problems of low reliability, easy sparks of flashers, etc., and achieves low cost, simple structure, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

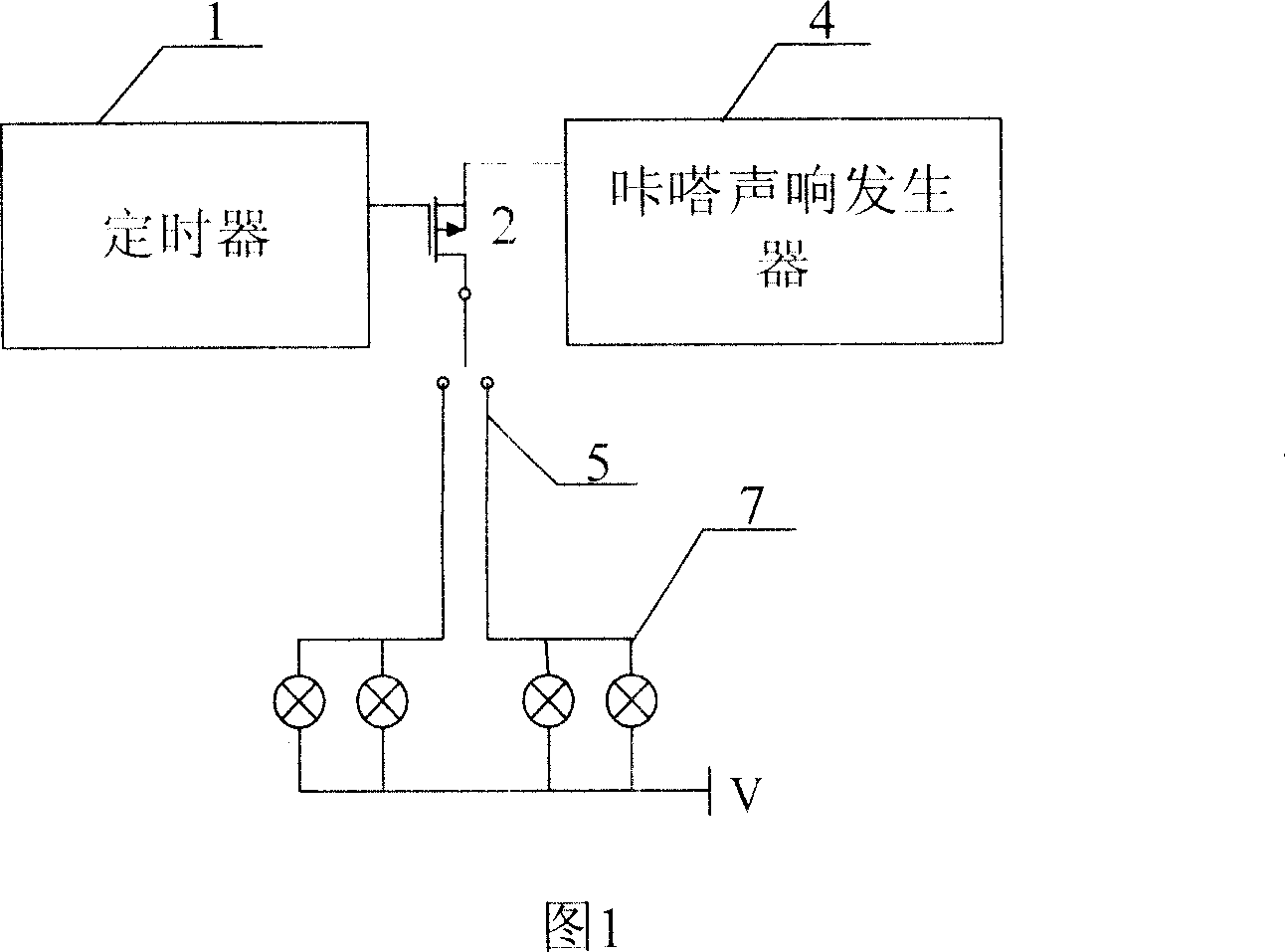

[0007] Specific embodiment one: the present embodiment will be specifically described below in conjunction with Fig. 1 and Fig. 2. This embodiment is composed of a timer 1, a VMOS tube switch 2, a click sound generator 4, a turn switch 5 and a display lamp group 7. The timing The output terminal of the device 1 is connected to the gate of the VMOS tube switch 2, the source of the VMOS tube switch 2 is connected to the moving end contact of the steering switch 5, and the drain of the VMOS tube switch 2 is connected to the input terminal of the click generator 4, and the steering The static end contact of the switch 5 is connected to one end of the display lamp group 7, and the other end of the display lamp group 7 is connected to the power supply V. After power on, the timer generates a timing signal to drive the VMOS tube switch at regular intervals, and the VMOS tube switch controls the flickering of the lamp. At the same time, the click sound generator generates the frequency...

specific Embodiment approach 2

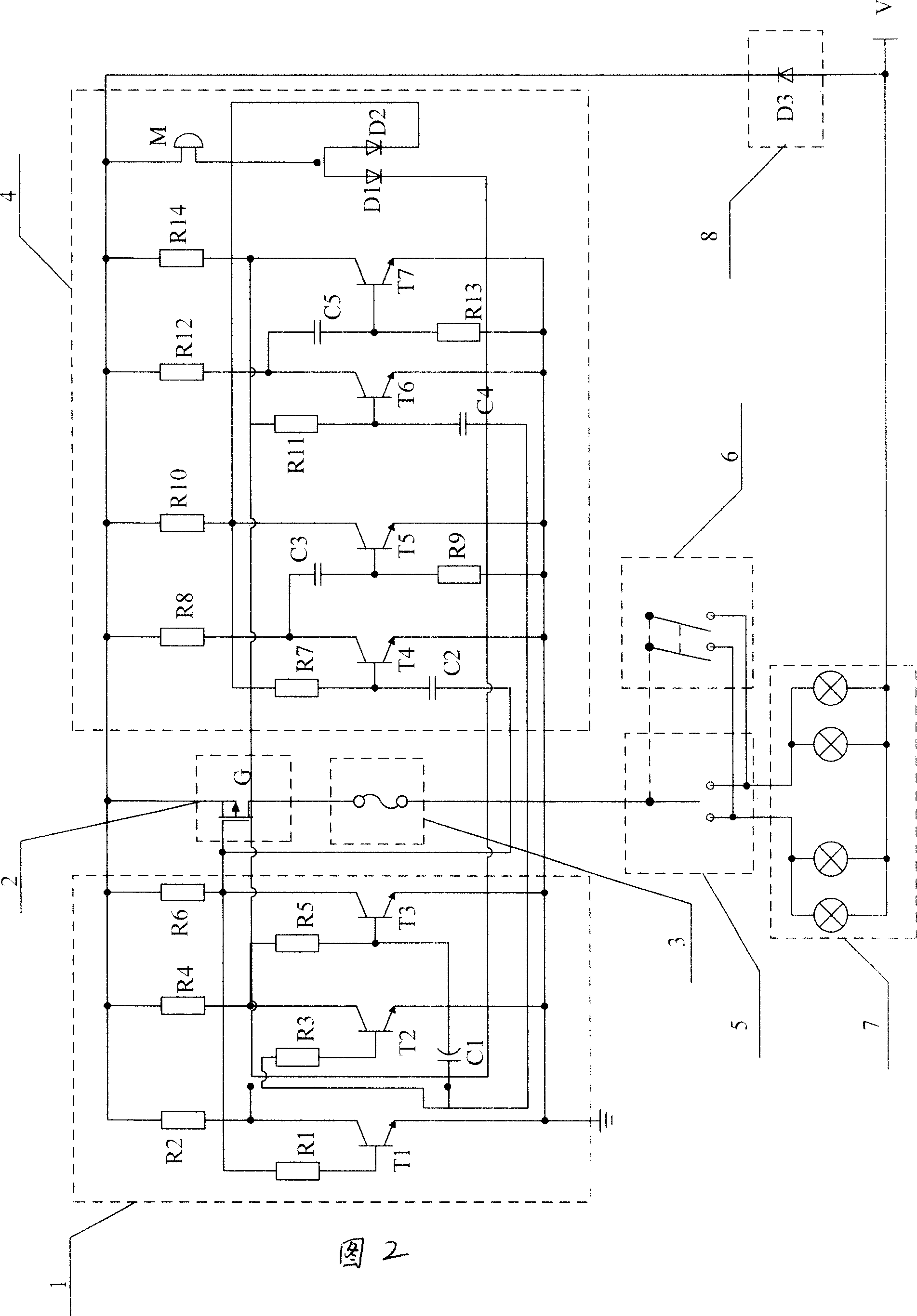

[0008] Specific embodiment two: The present embodiment will be specifically described below in conjunction with FIG. 2. The difference between this embodiment and the specific embodiment one is that the timer 1 is composed of a first resistor R1, a second resistor R2, a third resistor R3, and a fourth resistor R4. , the fifth resistor R5, the sixth resistor R6, the first capacitor C1, the first transistor T1, the second transistor T2 and the third transistor T3, one end of the first resistor R1 is connected to the base of the first transistor T1, the second The other end of a resistor R1 is connected to one end of the sixth resistor R6, the collector of the third transistor T3 and the gate of the VMOS transistor switch 2, and the collector of the first transistor T1 is connected to one end of the second resistor R2 and the gate of the third resistor R3. One end is connected to one end of the first capacitor C1, the emitter of the first transistor T1 is connected to the ground, ...

specific Embodiment approach 3

[0009] Specific embodiment three: the present embodiment will be described in detail below in conjunction with FIG. Resistor R10, eleventh resistor R11, twelfth resistor R12, thirteenth resistor R13, fourteenth resistor R14, second capacitor C2, third capacitor C3, fourth capacitor C4, fifth capacitor C5, fourth transistor T4, the fifth transistor T5, the sixth transistor T6, the seventh transistor T7, the first diode D1, the second diode D2 and the buzzer M, one end of the second capacitor C2 is connected to the VMOS transistor switch 2, the other end of the second capacitor C2 is connected to one end of the seventh resistor R7 and the base of the fourth transistor T4, and the other end of the seventh resistor R7 is connected to one end of the tenth resistor R10 and the collector of the fifth transistor T5 and the cathode of the second diode D2, the collector of the fourth transistor T4 is connected to one end of the eighth resistor R8 and one end of the third capacitor C3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com