Mixed driven cover turning apparatus suitable for different bottle mouth threads

A hybrid drive and thread technology, which is applied to screw caps and other directions, can solve the problems of increasing mechanical volume, product hygiene and safety, and inconvenient operation, and achieves the effects of increasing degrees of freedom, compact mechanism, and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

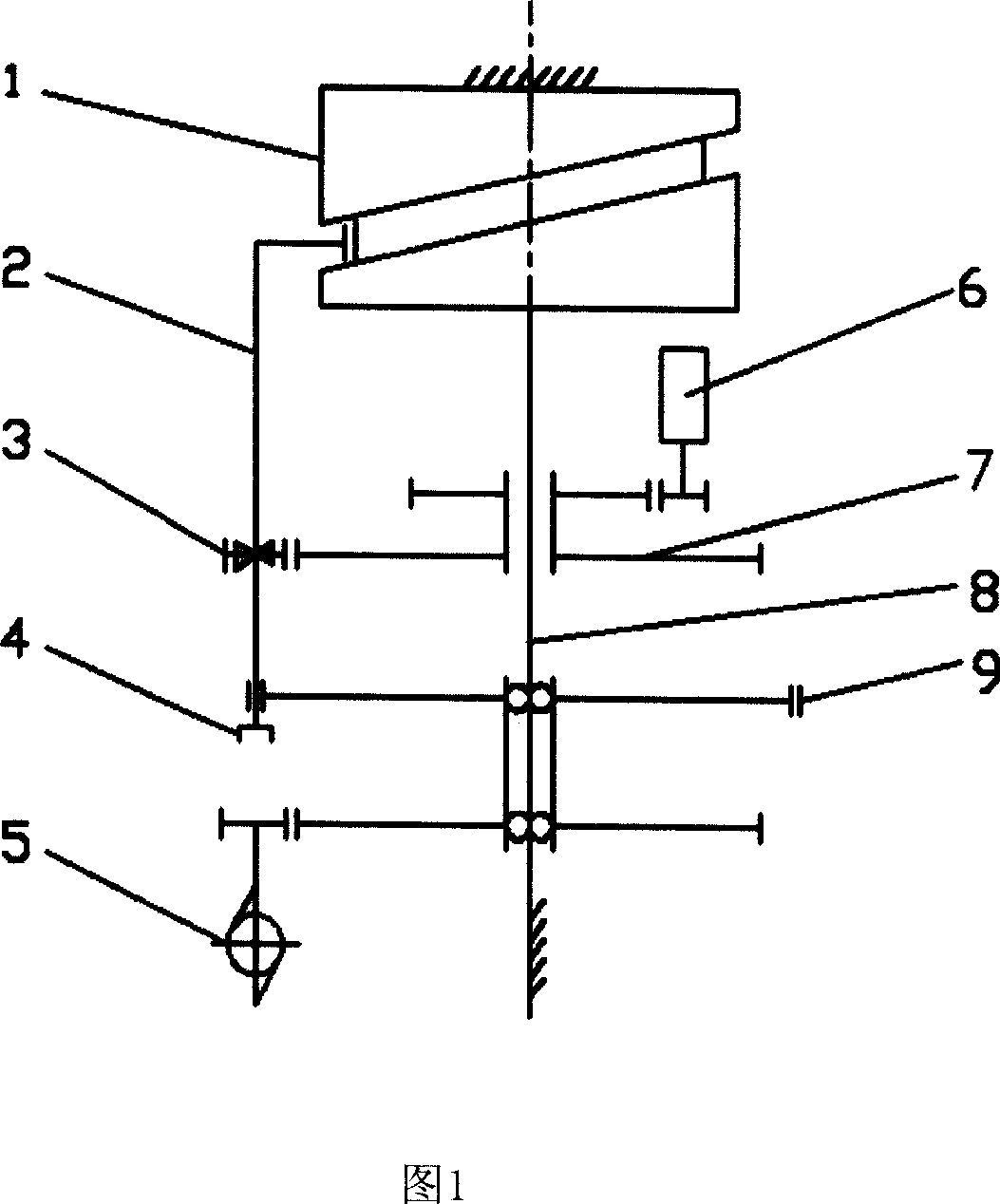

[0010] As shown in FIG. 1 , this embodiment includes a cam 1 , a push rod 2 , a planetary wheel 3 , a capping head 4 , a constant speed asynchronous motor 5 , a servo motor 6 , a center wheel 7 , a main shaft 8 , and a turntable 9 . The constant speed asynchronous motor 5 drives the turntable 9 to rotate around the main shaft 8. A plurality of capping heads 4 are fixed on the turntable 9 to rotate together with it. The rotation of the planetary wheel 3 provides power for the capping action of the capping head 9. The wheels 3 mesh, the center wheel 7 is driven by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com