Heat radiator for light truck

A technology for radiators and trucks, which is applied in the field of assembly parts for automobiles, can solve problems affecting normal work, affecting corrosion resistance, and fractures, and achieves the effects of reasonable structural design, improved corrosion resistance, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

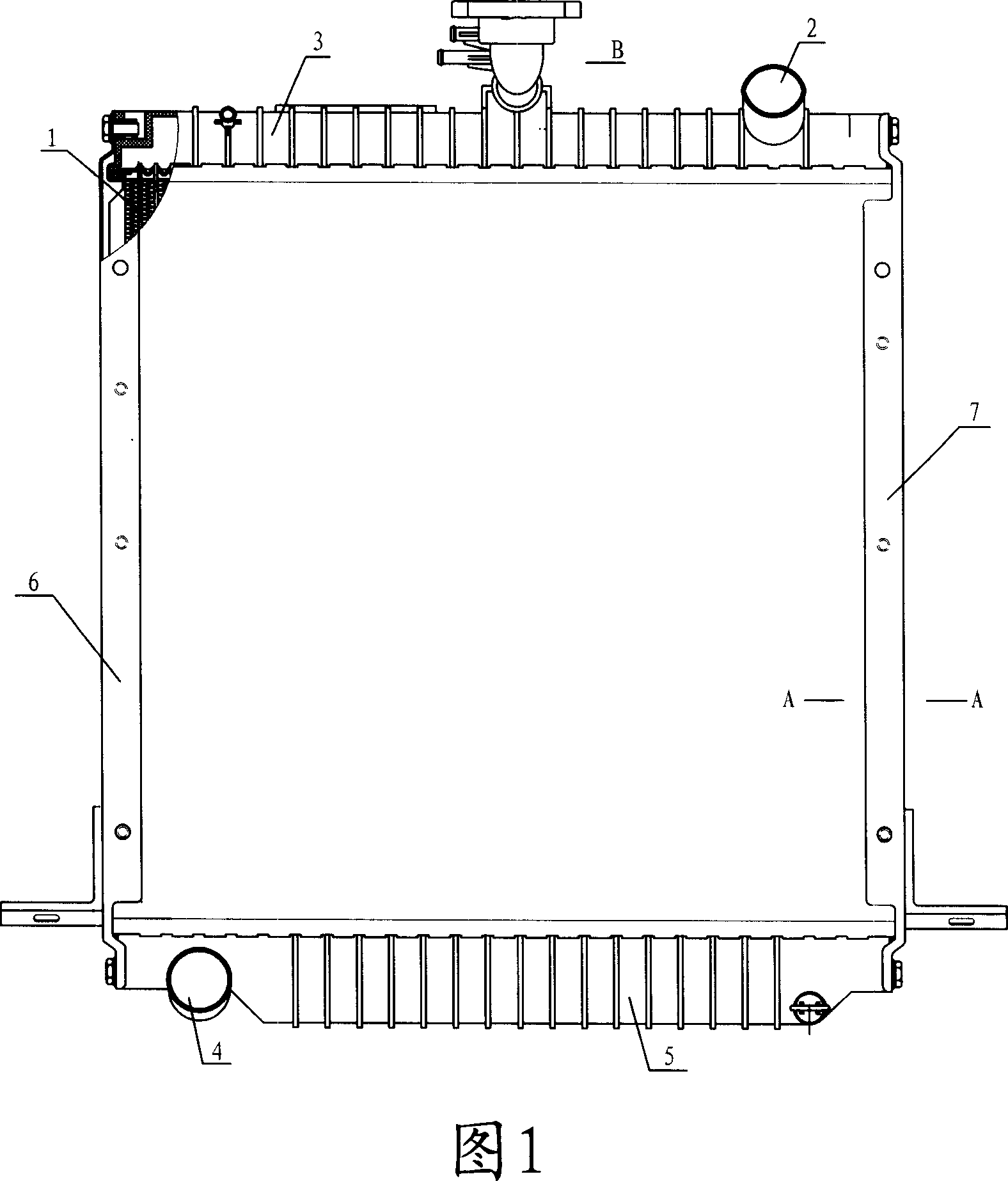

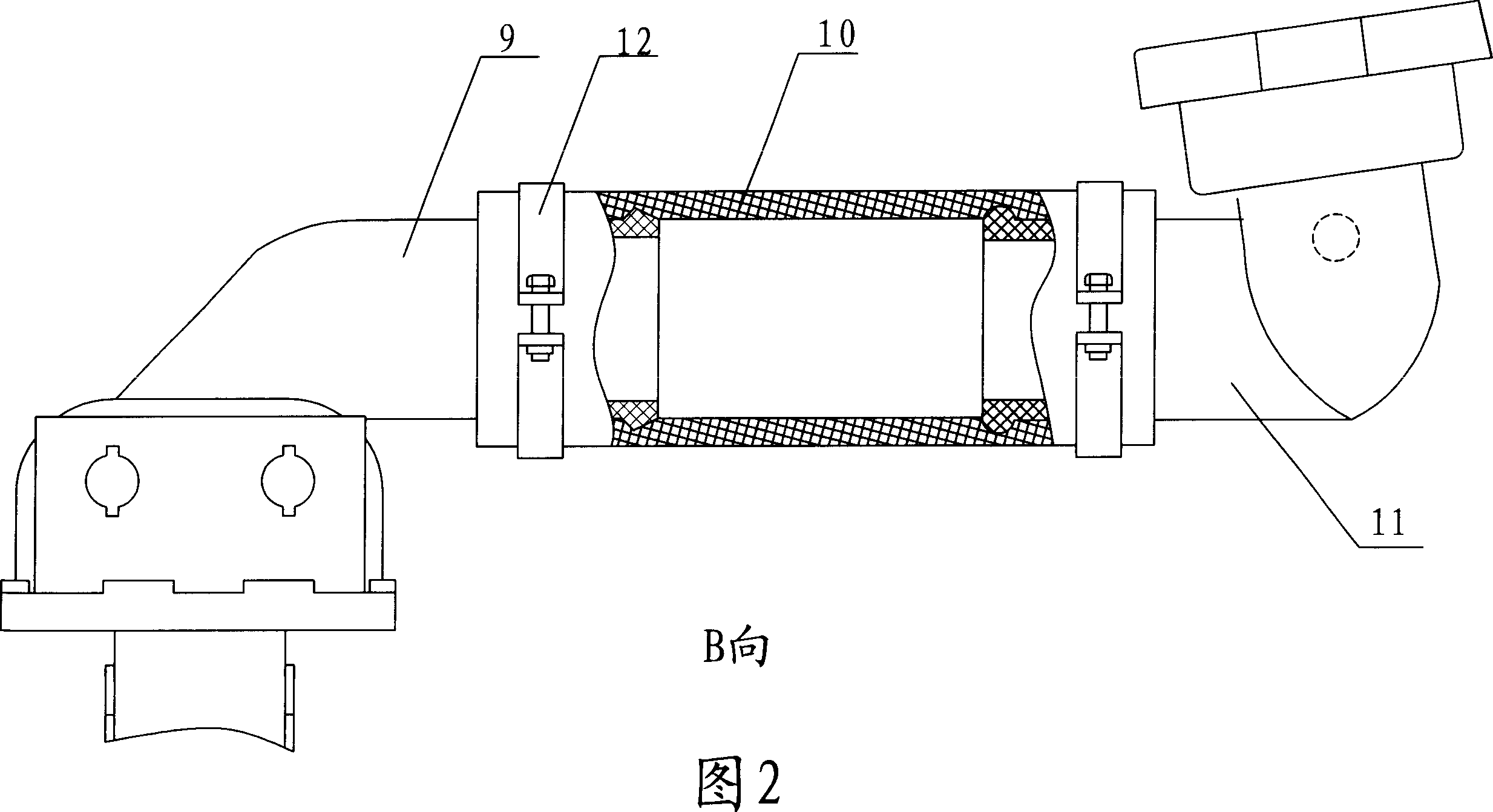

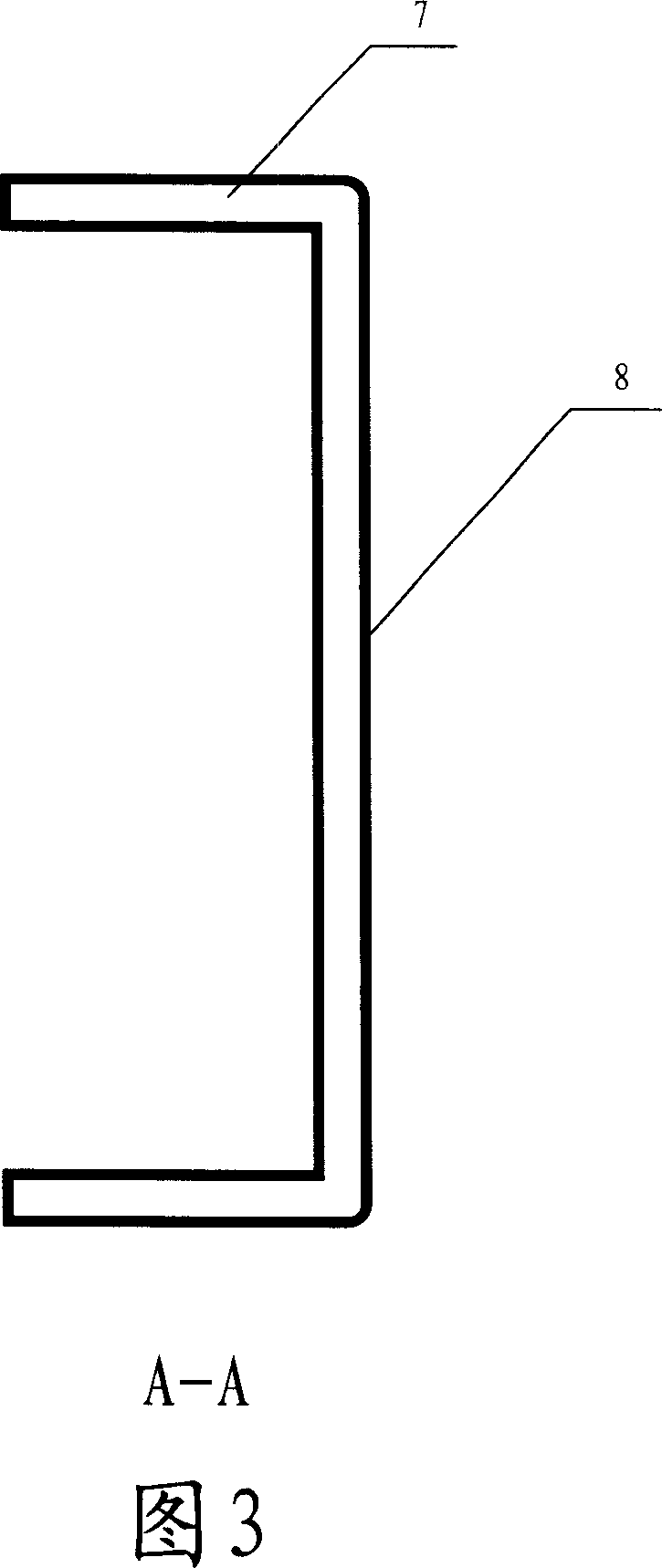

[0015] Shown in Fig. 1, 2, 3 is the specific embodiment of the present invention, and it is the light-duty truck radiator that one deck galvanized layer 8 is electroplated on the outer surface of left and right side plates, and it comprises aluminum radiator core body 1, The upper water chamber 3 with the water inlet 2, the lower water chamber 5 with the water outlet 4, the left and right side plates 6, 7 are characterized in that the outer surfaces of the left and right side plates 6, 7 made of cold-rolled plates are electroplated One layer of silver-white galvanized layer 8 makes its color consistent with the silver-white aluminum heat dissipation core 1, and is connected to the middle position of the top of the upper water chamber 3 by the water inlet seat 11, the rubber hose 10, and the water pipe 9. , water inlet 10, the soft water adding pipe that stainless steel pipe collar 12 forms.

[0016] The above is only a preferred embodiment of the present invention, but the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com