Flexible three dimension holographic measuring system

A technology of 3D holography and measurement system, which is applied in measurement devices, instruments, and optical devices, etc., can solve problems such as strong comprehensiveness and no reasonable solution has been found, and achieves improved scanning accuracy, fast and efficient 3D surface scanning without blind spots, The effect of high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

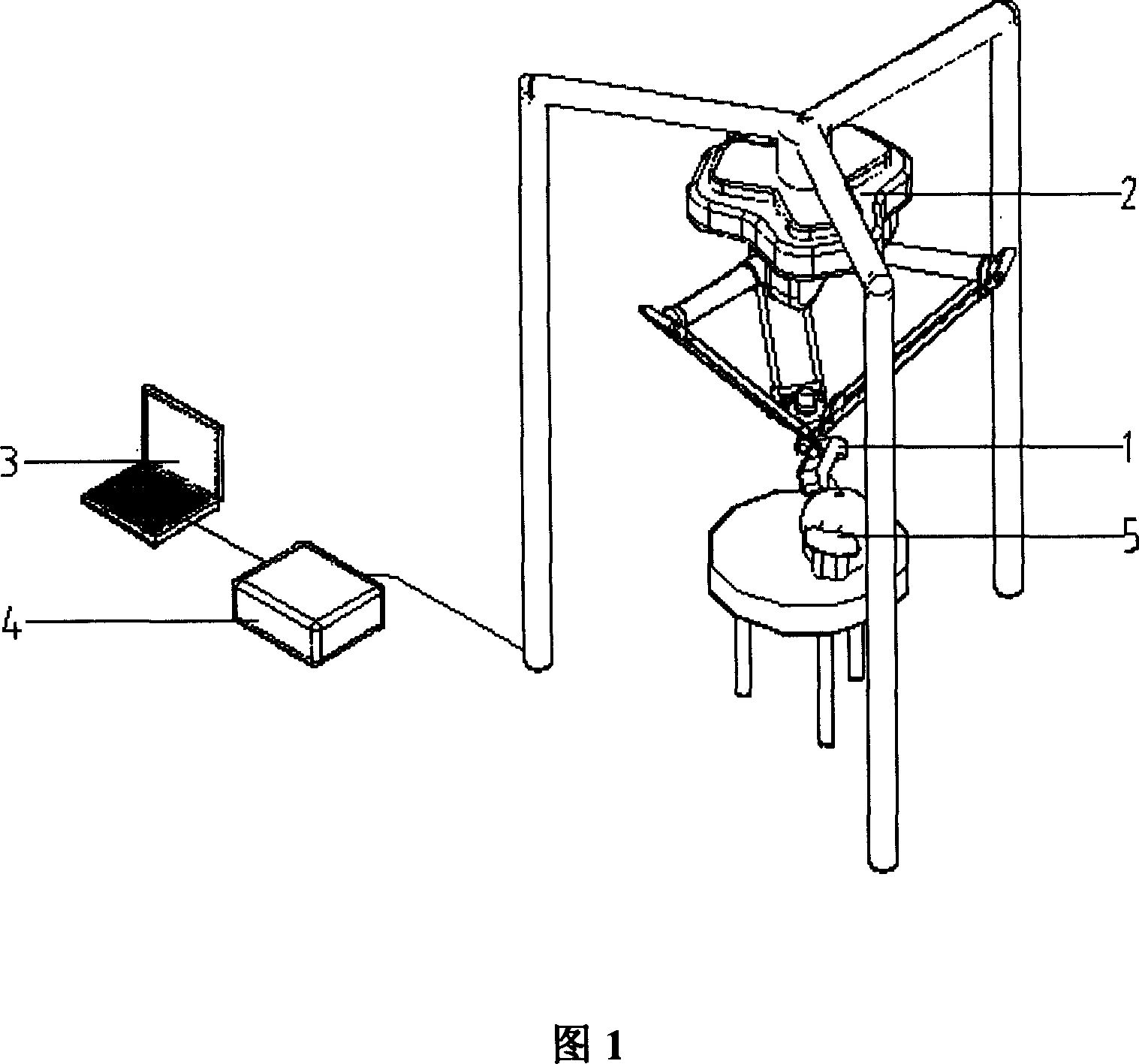

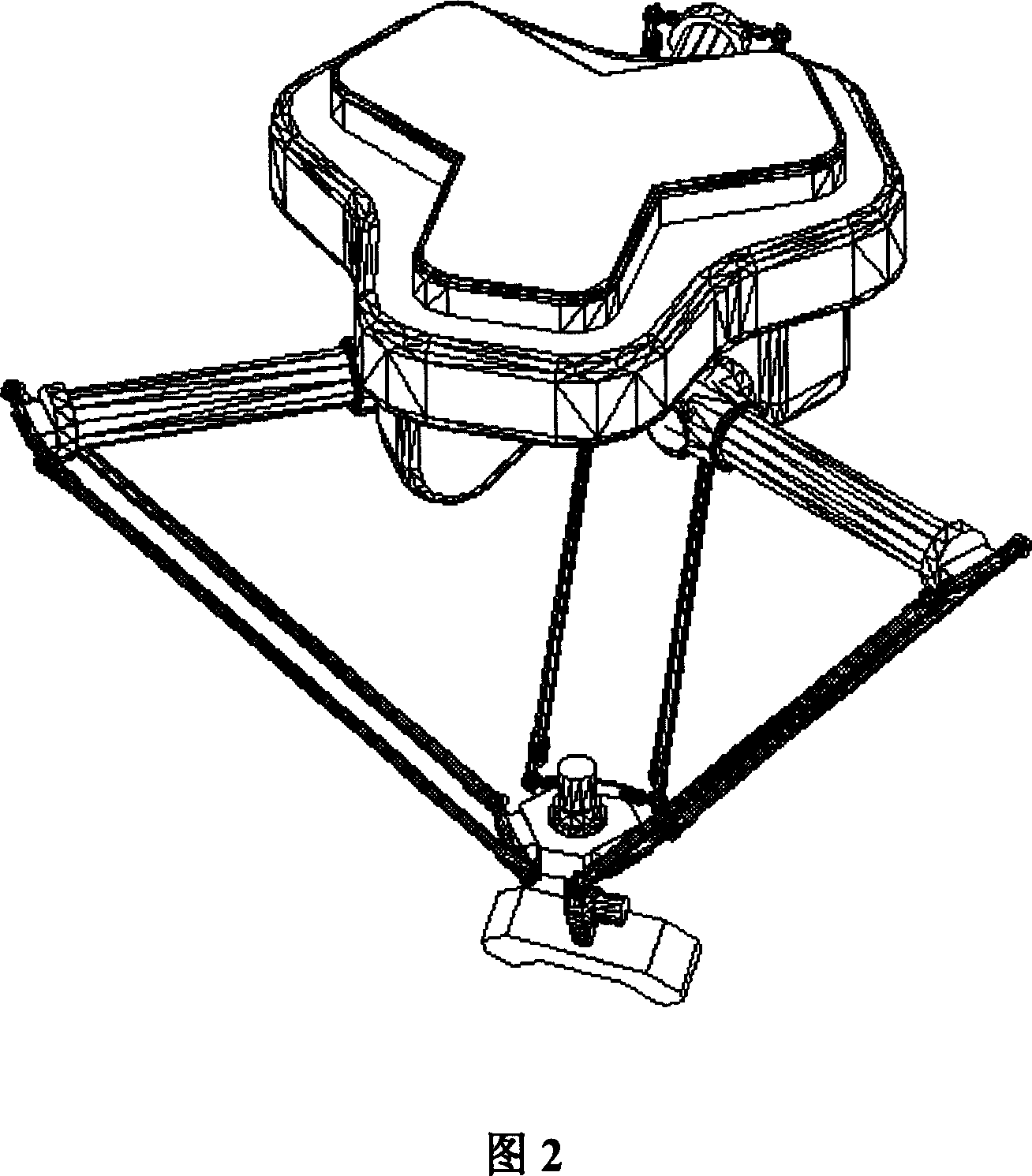

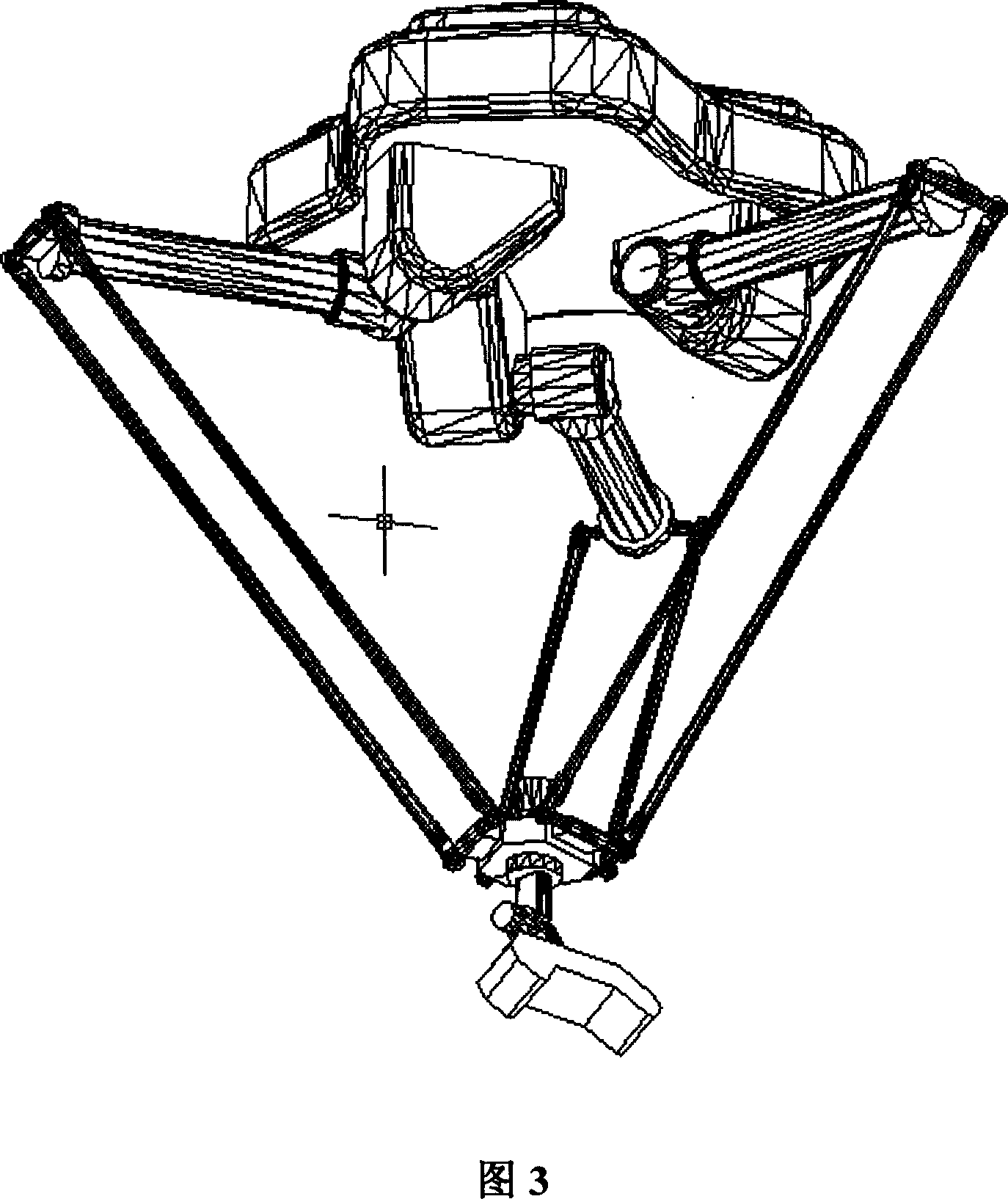

[0039] The present invention mainly comprises following five parts:

[0040] (1) Parallel 3D measuring robot

[0041] (2) The planning of the scanning path is mainly the estimation of the coordinates and normal vectors of the points to be measured.

[0042] (3) Coordinate transformation and three-dimensional display of scanned data.

[0043] (4) Data post-processing, including points, lines, and surfaces.

[0044] (5) An evaluation of the processing quality of the scanned surface is given.

[0045] The following combines the above content to give a detailed introduction to the scanning of an engine component:

[0046] Step 1: Input the basic parameters of the workpiece to be tested

[0047] Size: 40×35×15cm 3

[0048] Material: cast iron

[0049] Surface Roughness: 3.2

[0050] Scanning step: 0.2mm

[0051] Step 2: Rough Scanning

[0052]The second method using path planning is the path planning method based on scan data. Divide the scanning process into two phases:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com