Positioning machine table

A positioning machine and positioning device technology, applied in the direction of conveyor objects, optics, instruments, etc., can solve the problems of large glass substrate size, broken glass substrate, and lower pass rate, so as to avoid damage or missing corners, high cost, and The effect of not falling easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

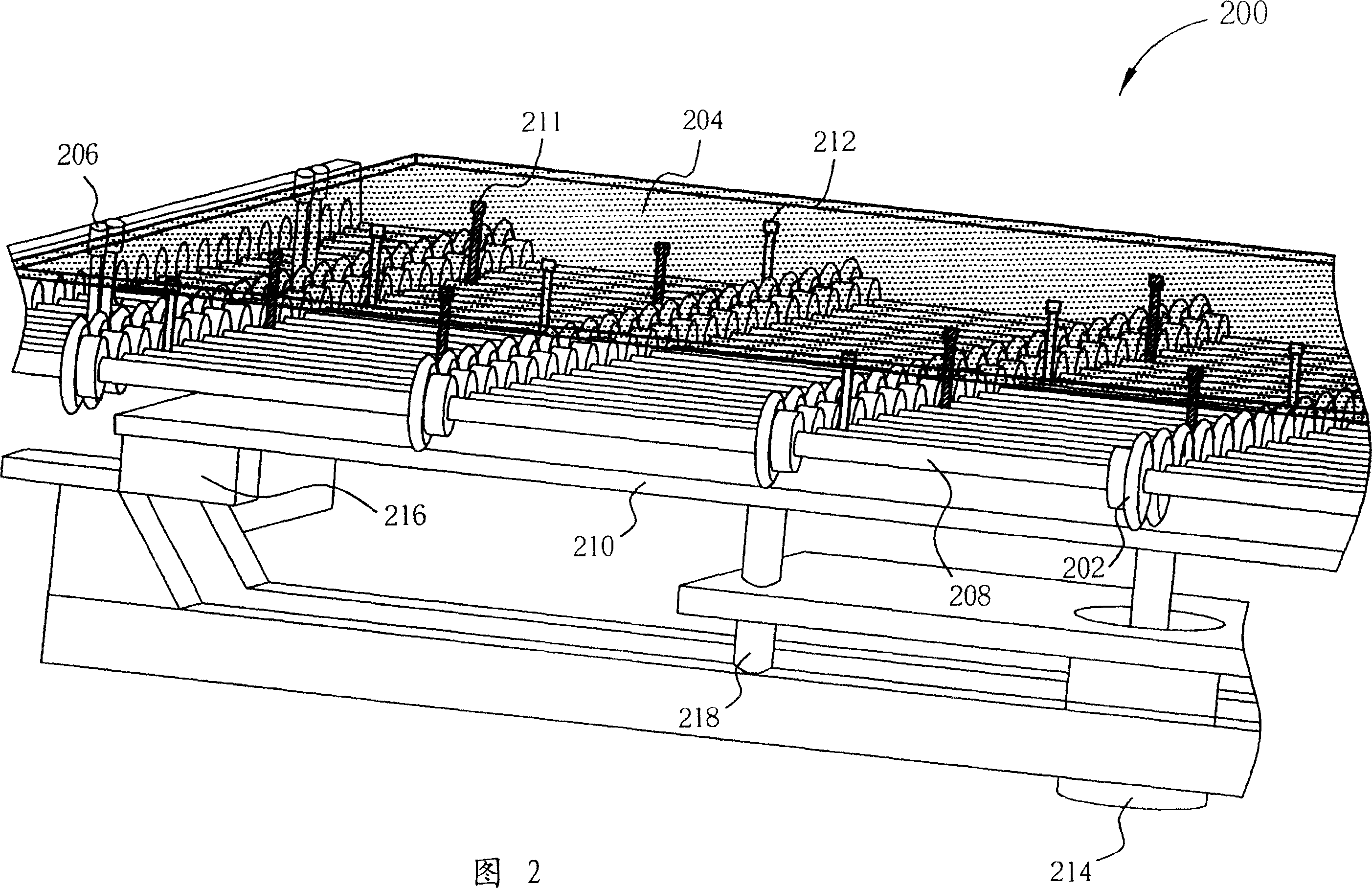

[0021] Please refer to FIG. 2 . FIG. 2 is a three-dimensional schematic view of the positioning machine of the present invention. The alignment machine 200 is an alignment machine for a glass substrate 204 such as a color filter (CF) substrate, a thin film transistor (TFT) substrate, or a plain glass substrate. Before the glass substrate 204 is to be processed in the next stage, the glass substrate 204 must be positioned first before being transported to an inspection machine (not shown) or a repair machine (not shown) by a robot or manually. As shown in FIG. 2 , the positioning machine 200 includes a roller 202 , a conveying track 208 , a lifting device 210 and a positioning device 206 . Wherein, each conveying track 208 is equipped with a plurality of rollers 202 at equal intervals, and the linear bearings 218 are used to drive each conveying track 208 to rotate, and the rollers 202 are rotated together, so that the rollers 202 can transport the glass substrate 204 to the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com