Device for transfer of flat display panel

A technology for conveying flat panel displays and substrates. It is applied to conveyors, conveyor objects, transportation, and packaging. It can solve problems such as increased manufacturing costs, increased substrate processing time, and reduced production efficiency, reducing installation space and reducing cycle time. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

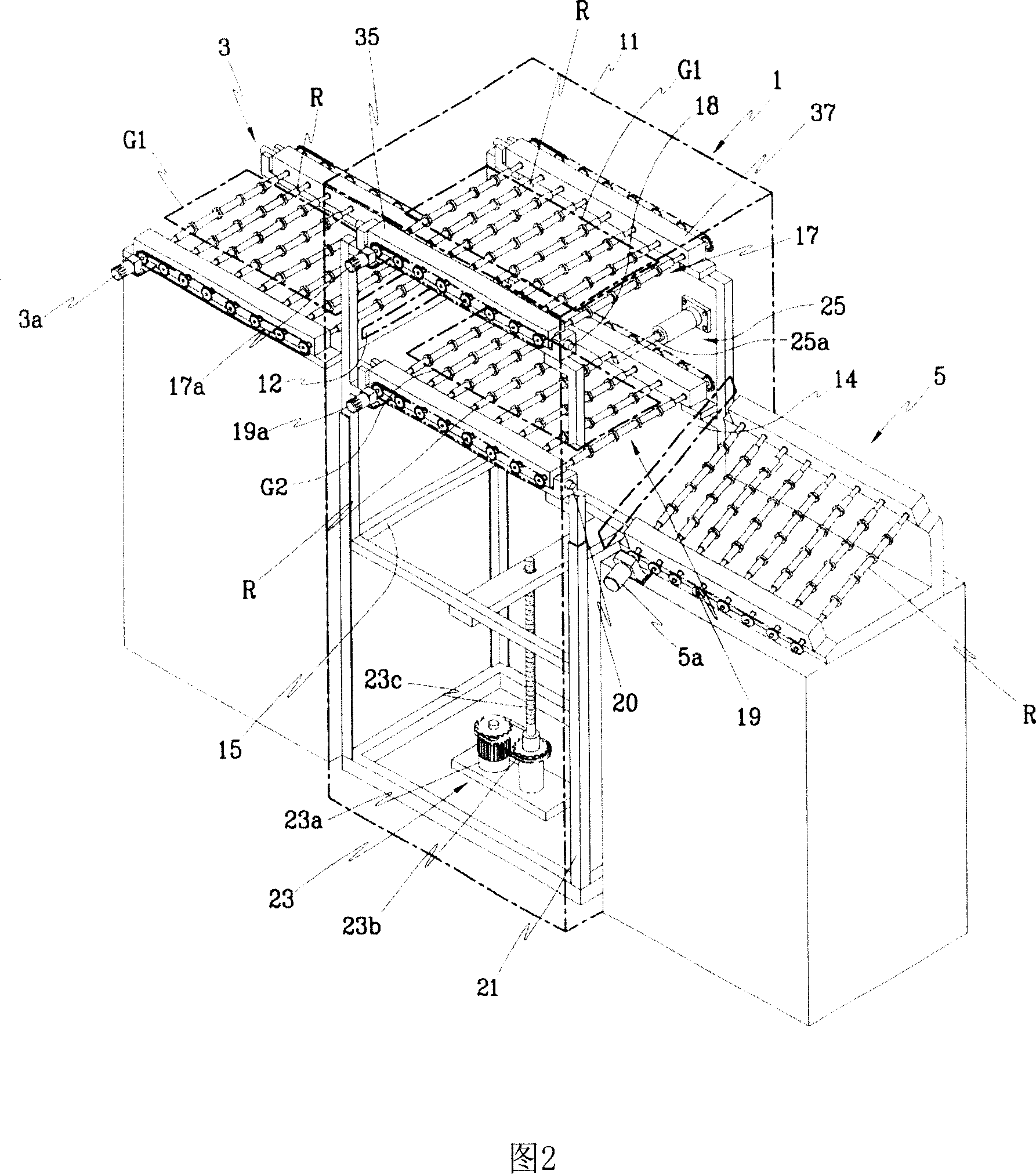

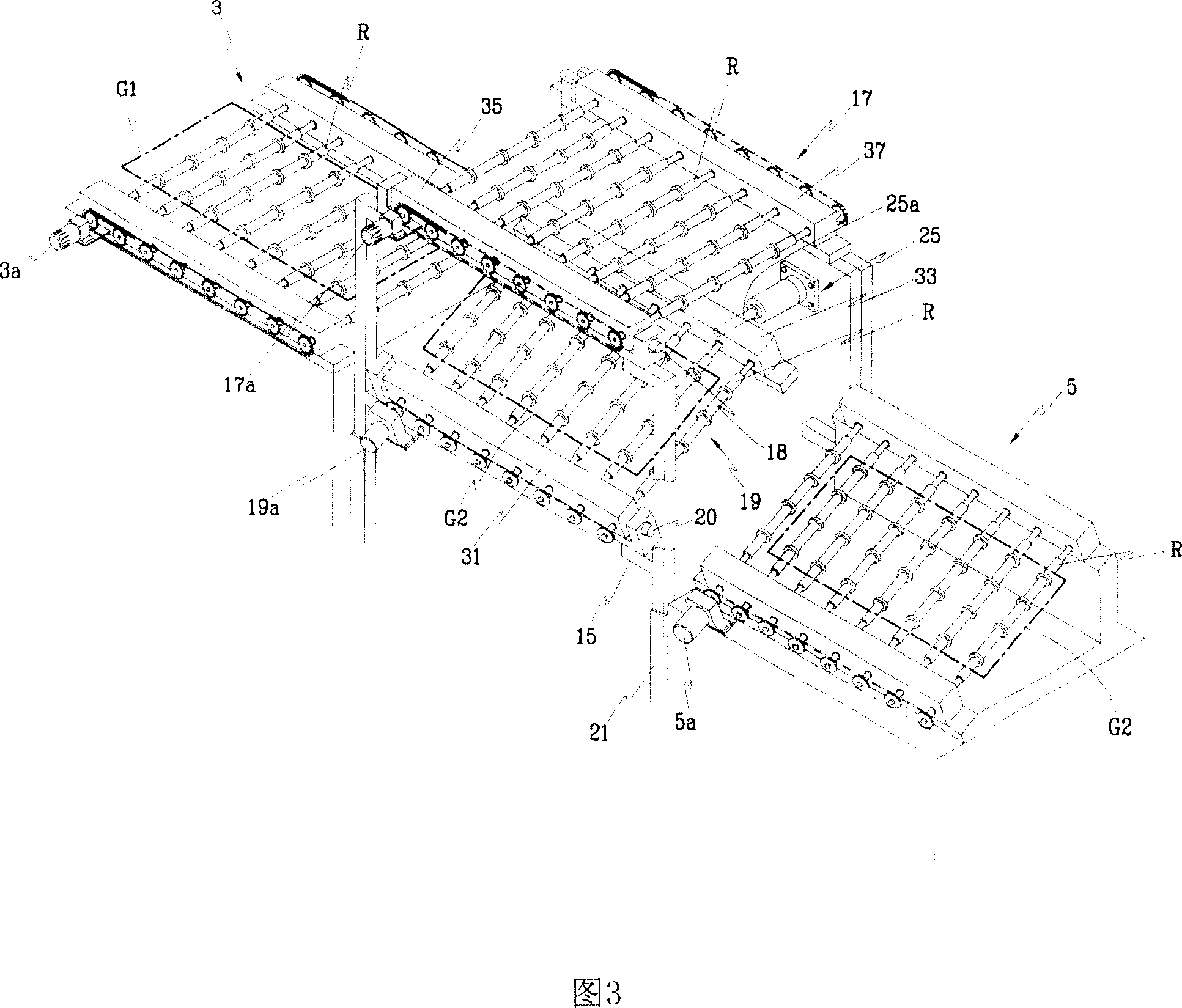

[0013] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

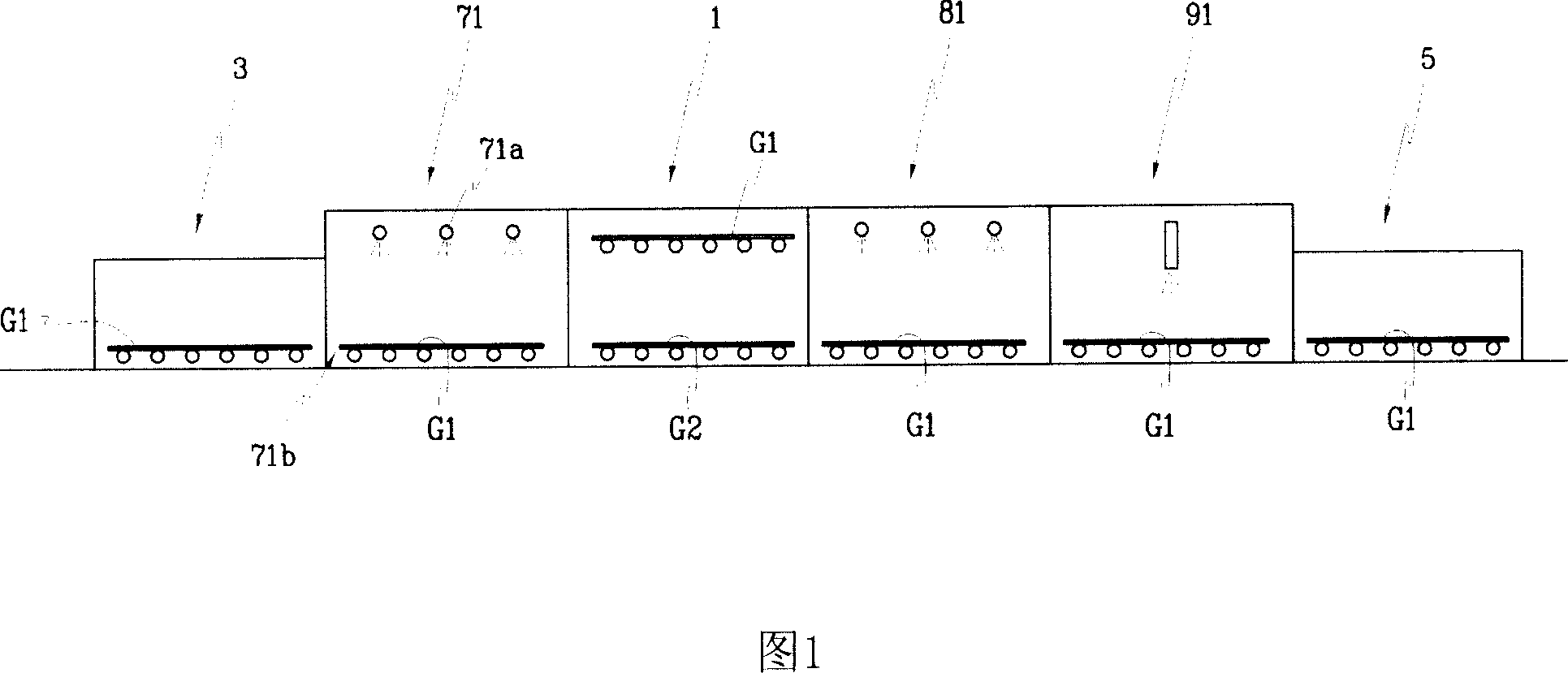

[0014] Fig. 1 is a structural diagram for explaining an embodiment to which the present invention is applied, showing a developing device. The developing device of the present invention includes: a substrate supply unit 3 for supplying substrates such as glass substrates; a developer spray unit 71 for receiving the substrate G1 (or G2) to be processed from the substrate supply unit 3, The substrate G1 (or G2) is coated with a developing solution; the developing part 1 is used to receive the substrate G1 (or G2) from the developing solution spraying part 71, and set aside the time required for developing the substrate for developing; the cleaning part 81, which can receive the substrate G1 (or G2) from the developing section 1 in an inclined state and clean it; a drying section 91, which is used to receive the substrate G1 (or G2) from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com