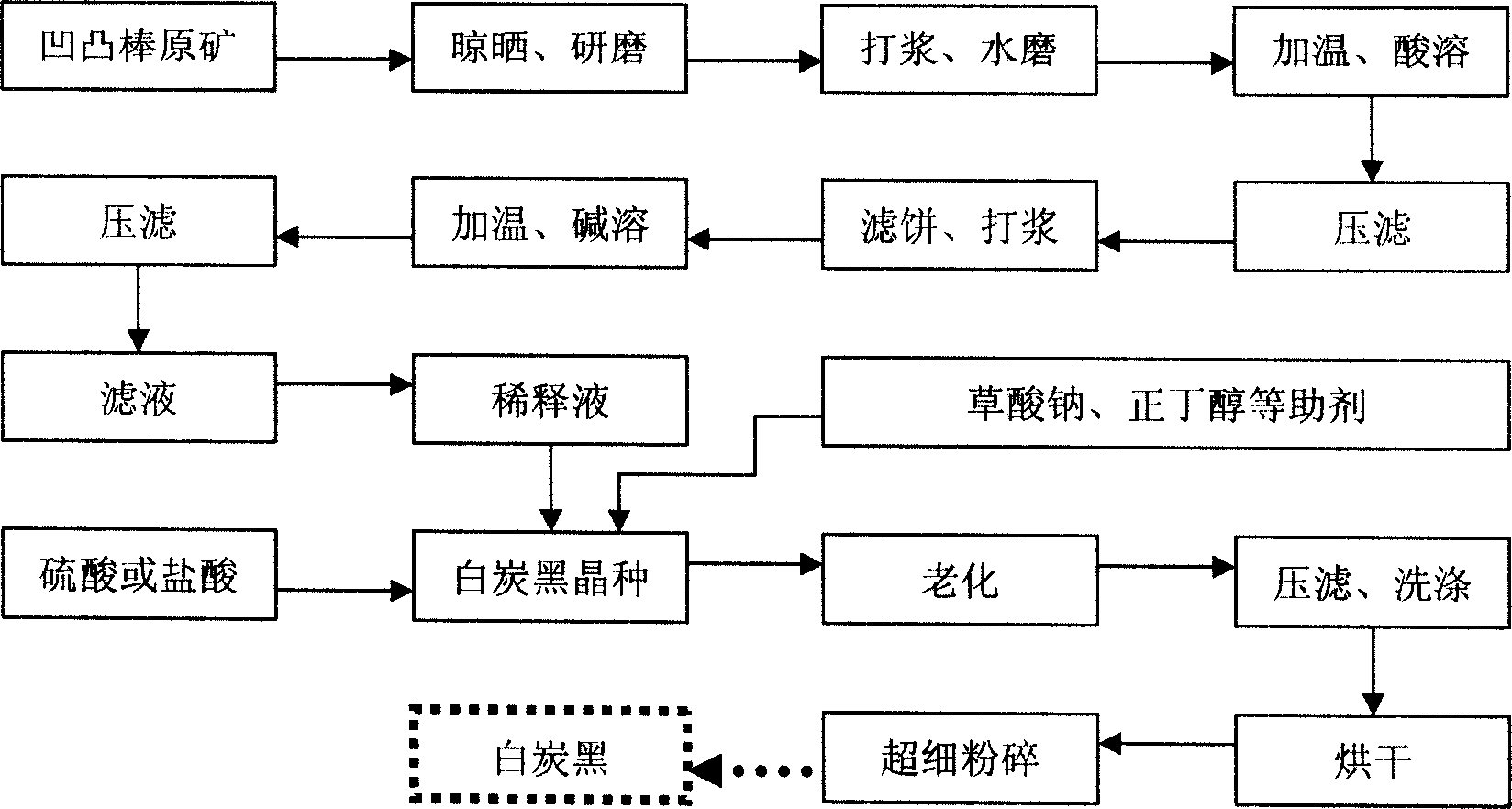

Process for preparing white carbon black using attapulgite clay

A technology of attapulgite clay and attapulgite, applied in the direction of silica, etc., can solve the problems of low activity of rod-shaped silica, low purity of silica, and difficulty in removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Crush attapulgite to 200 mesh, take 50g of powder and add 150ml of distilled water, stir to make a suspension, then add about 2g of sodium hexametaphosphate, continue to stir and disperse for 1 hour; transfer the above suspension into a reaction vessel, At 100°C, add 15ml of sulfuric acid to react for 3 hours; after the reaction is completed, wait for the slurry to cool, then vacuum filter, and wash the filter cake with water three times; transfer the filter cake to a reaction vessel, add 250ml of water, and add 1g of sodium oxalate and 16g of Sodium hydroxide, react at 100°C for 2h. After vacuum filtration, the filtrate was transferred to a reaction kettle, and 150ml of distilled water was added at the same time, and 25% sulfuric acid was slowly added under stirring conditions at 50°C until the pH of the solution was about 7.0 to obtain white carbon black "seed crystals". After aging for 2 hours, the "seed crystal" was put into water glass and sulfuric acid solution at...

Embodiment 2

[0048] Take 50g of attapulgite powder of 200 mesh and add 150ml of distilled water, stir to form a suspension, then add about 2g of sodium hexametaphosphate, continue to stir and disperse for 1 hour; transfer the above suspension into a reaction vessel, at 100°C, Add 18ml of sulfuric acid to react for 3 hours; after the reaction is completed, wait for the slurry to cool, then vacuum filter, wash the filter cake with water three times; transfer the filter cake to a reaction vessel, add 250ml of water, add 1g of sodium oxalate and 18g of sodium hydroxide while stirring, Reaction at 100°C for 2h. After vacuum filtration, the filtrate was transferred to the reaction kettle, and 150ml of distilled water was added at the same time, and 30% hydrochloric acid was slowly added at 50°C under stirring conditions until the pH value of the solution was about 7.0 to obtain white carbon black "seed crystals" and placed for 2 hours Then put water glass and hydrochloric acid solution at the sa...

Embodiment 3

[0050]Take 50g of attapulgite powder of 200 mesh and add 150ml of distilled water, stir to form a suspension, then add about 2g of sodium hexametaphosphate, continue to stir and disperse for 1 hour; transfer the above suspension into a reaction vessel, at 100°C, Add 18ml of sulfuric acid to react for 3 hours; after the reaction is completed, wait for the slurry to cool, then vacuum filter, wash the filter cake with water three times; transfer the filter cake to a reaction vessel, add 250ml of water, add 1g of sodium oxalate and 18g of sodium hydroxide while stirring, Reaction at 100°C for 2h. After vacuum filtration, the filtrate was transferred to a reaction kettle, and 150ml of distilled water and 5ml of n-butanol were added at the same time, and 30% hydrochloric acid was slowly added at 50°C under stirring conditions until the final pH value was stable at 8-9. The prepared white carbon black slurry was vacuum filtered and washed about three times, dried at 120° C., and grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com