Composite assembled corner hardware and production method thereof

A technology for forming corner codes and production methods, which is applied to windows/doors, building components, buildings, etc., can solve the problems of complex processes, waste of aluminum resources, easy deformation, etc., to ensure overall firmness, energy saving and Material, effect of strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

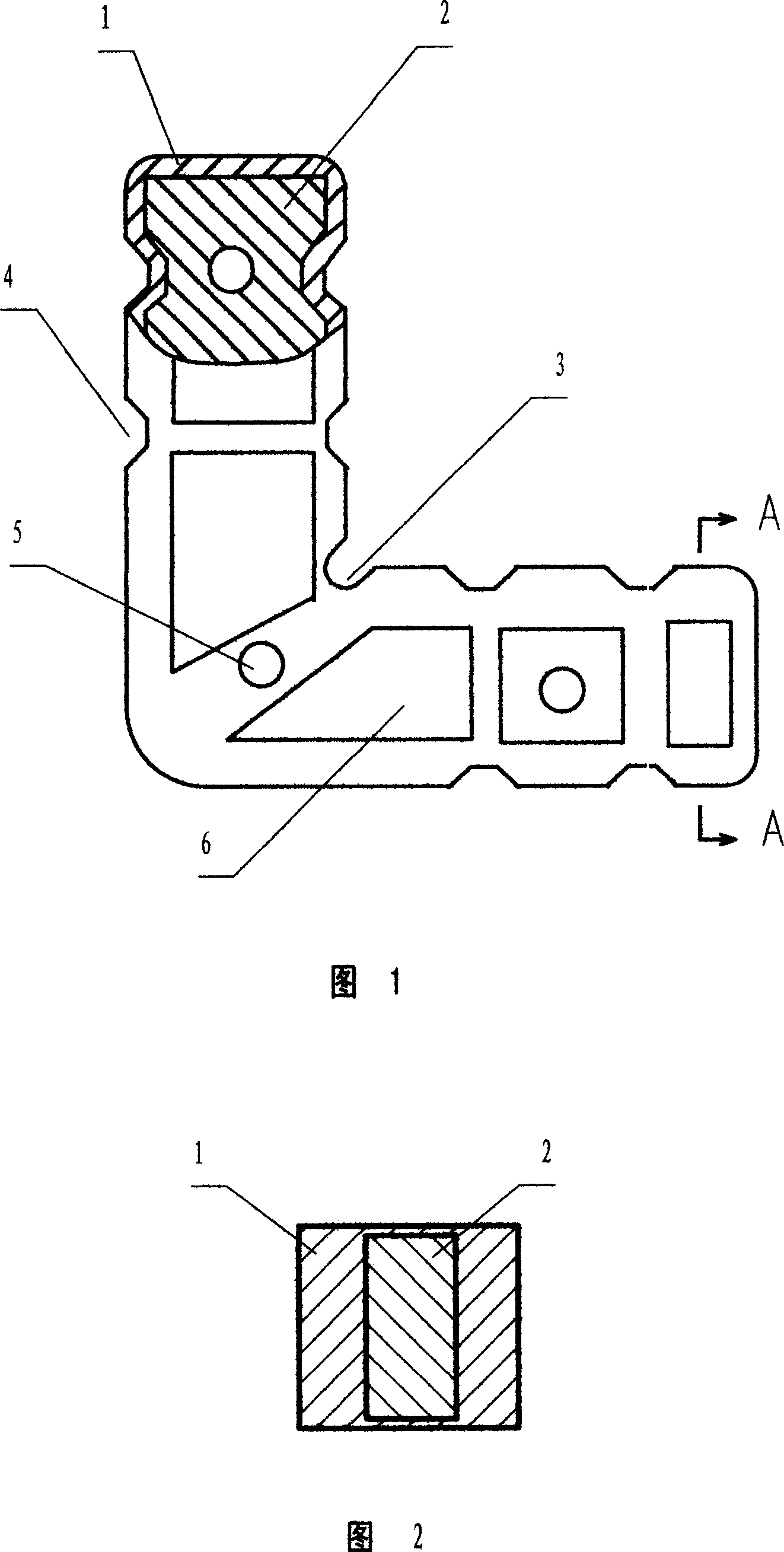

[0024] The embodiment of compound group corner code: a kind of compound group corner code as shown in Figure 1, 2, is L-shaped structure, and this corner code includes L-shaped support layer 2, and the L that overlaps with support layer 2 type nylon layer 1, and the supporting layer 2 is fixedly connected with the nylon layer 1. Wherein the nylon layer 1 is two layers and is arranged on both sides of the supporting layer 2 . The support layer 2 is a reinforced steel plate, which strengthens the strength of the corners and the hardness of the corners; the nylon layer 1 is made of polyamide nylon (PA66) and glass fiber, which can greatly improve the firmness of the corners of the whole door and window . At the same time, there is an extruded corner groove 3 at the included corner of the L-shaped corner, so that the glue injection can guide the flow more effectively, so that the corner and the aluminum can be fixed together to achieve the best effect of corner sealing and streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com