Photoelectric conversion element array, its integrated device, their packaging structure, and optical information processor

A technology for photoelectric conversion elements and integrated devices, which can be used in electrical components, optical components, electrical solid-state devices, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

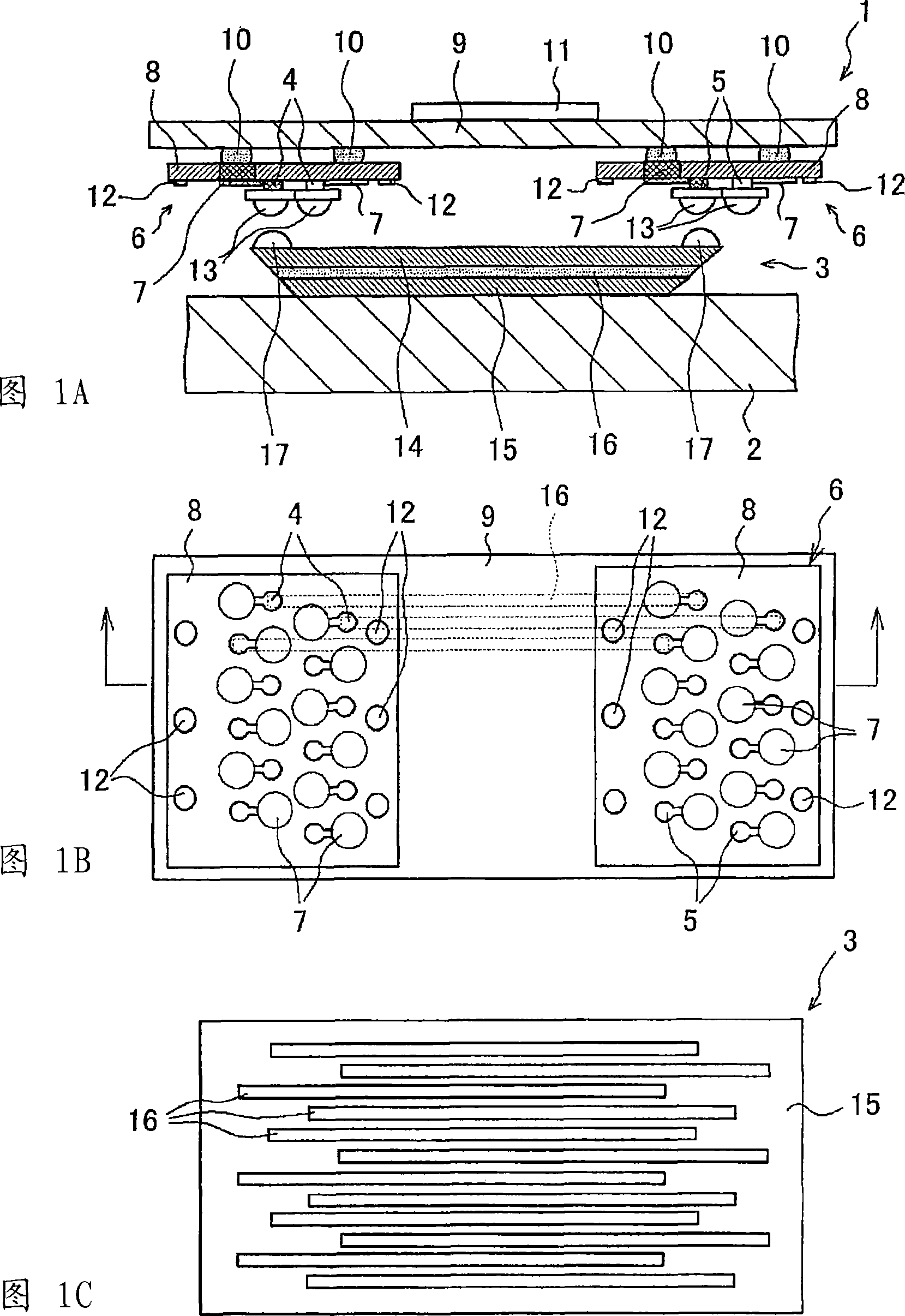

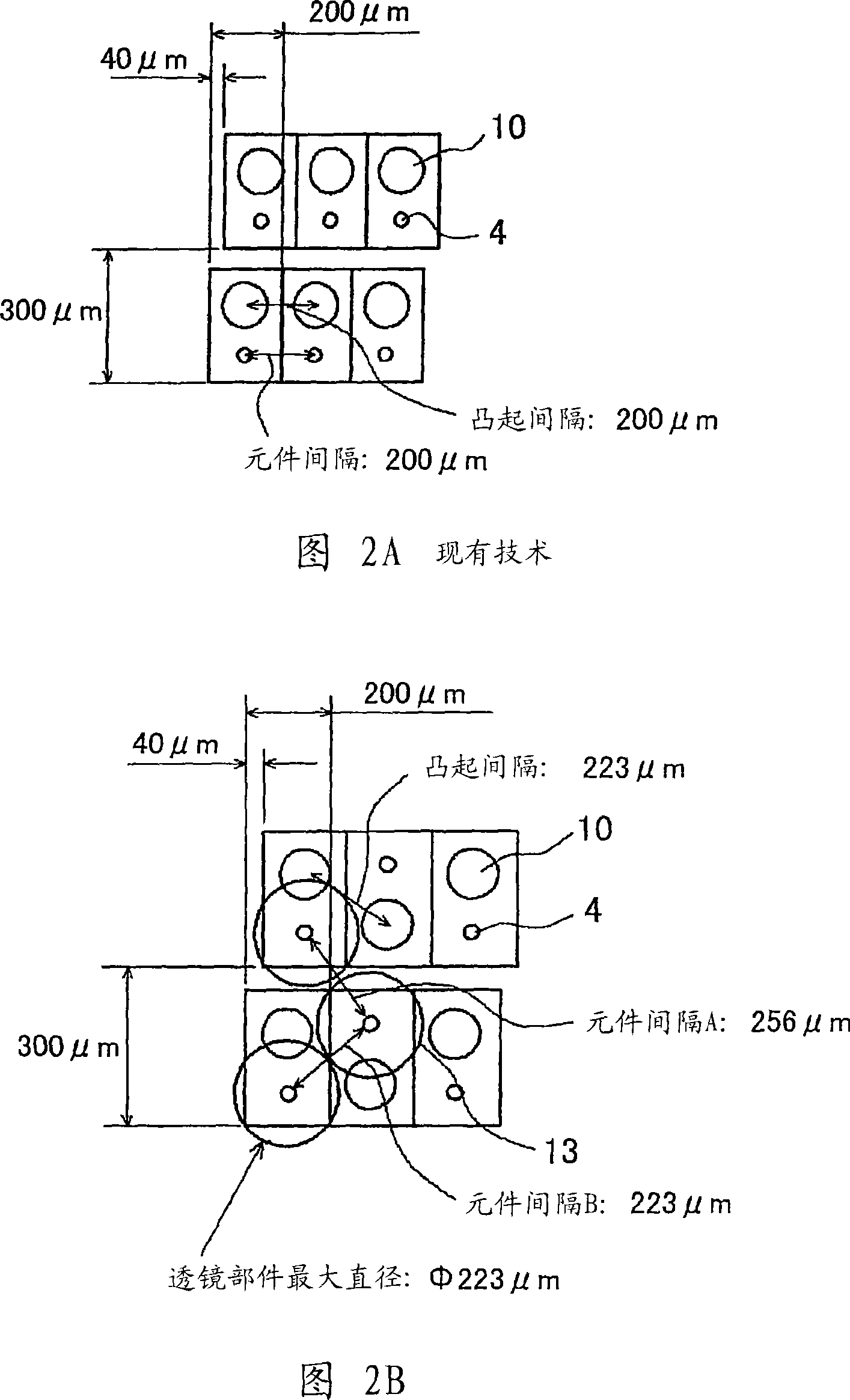

[0043] 1A to 1C are schematic diagrams of a photoelectric conversion element array integration device and an optical information processing device based on the present invention. As shown in FIG. 1A, in an optical information processing device 1 based on the present invention, an optical waveguide 3 is formed on a printed wiring board 2, and the signal-modulated light ( For example, laser light) enters the optical waveguide 3, the incident light is guided in the optical waveguide 3, and the light emitted from the optical waveguide 3 is received by the photosensitive element (eg, photodiode) 5 as the photoelectric conversion element. In this manner, an optical transmission and communication system using the optical waveguide 3 as a transmission path for signal-modulated laser light or the like can be constructed.

[0044] In addition, as shown in FIG. 1A and FIG. 1B, the photoelectric conversion element array integration device 6 of the present invention is composed of a plural...

no. 2 approach

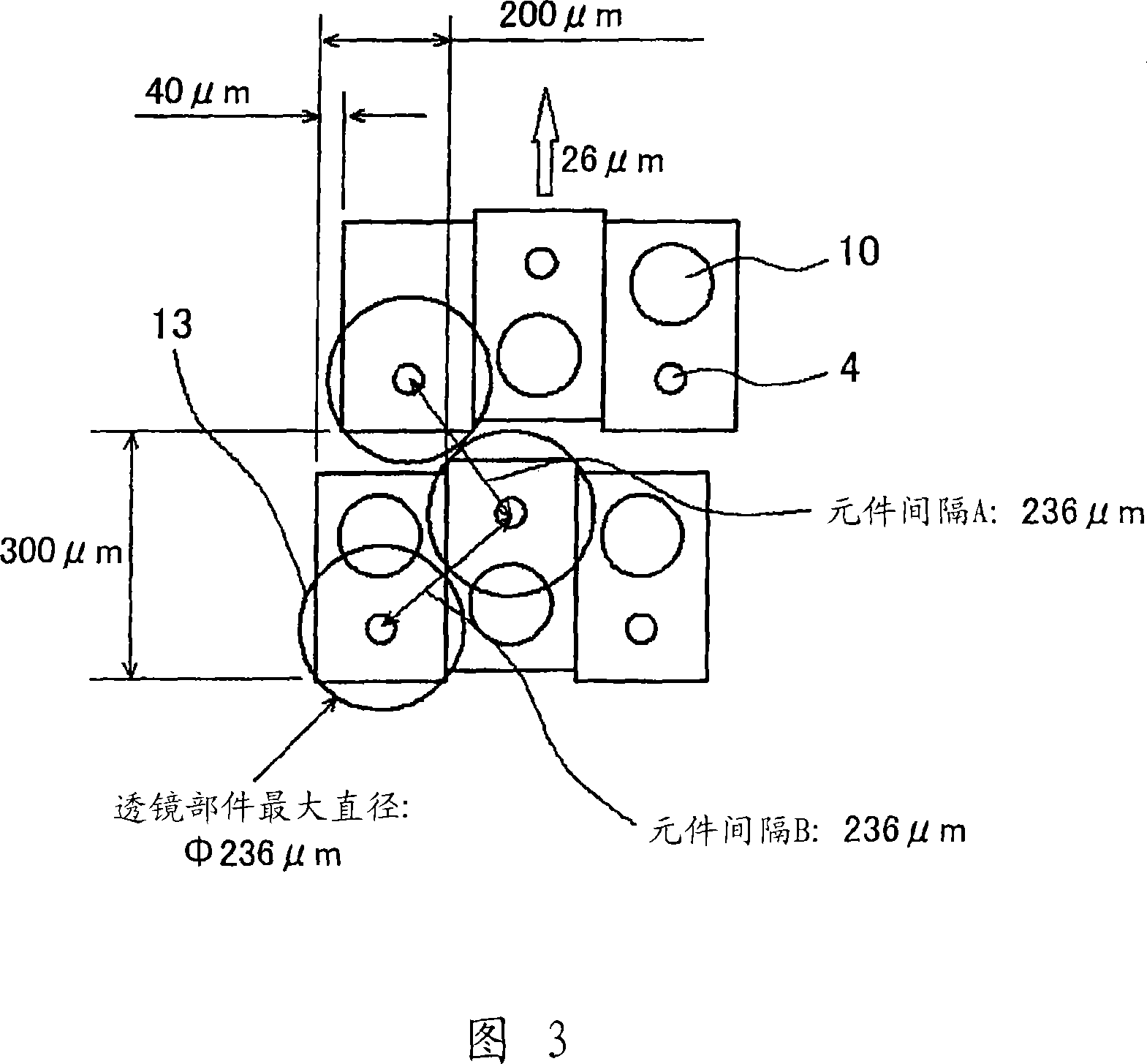

[0063] In order to further increase the distance between adjacent photoelectric conversion elements 4, 5, as shown in FIG. Waveguide direction shift (eg 26 μm). Therefore, the element interval A between the photoelectric conversion element arrays (and the distance between adjacent solder bumps 10) can be 236 μm, and the element interval B in the same photoelectric conversion element array can be 236 μm. , can be formed larger than the configuration example of the first embodiment shown in FIG. 2B . Furthermore, the maximum diameter of the lens member 13 can be φ236 μm, which can be formed larger than the arrangement example of the first embodiment shown in FIG. 2B . Thereby, the combining efficiency of light can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com