Method for the manufacture of a fibre composite component, a reinforcement element and also a fibre composite component

a technology of fibre composite components and components, applied in the direction of transportation and packaging, other domestic articles, chemistry apparatus and processes, etc., can solve the problems of increasing assembly costs and the weight of the fuselage shell, and achieve the effect of improving adhesive bonded joints and/or bonding and high loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

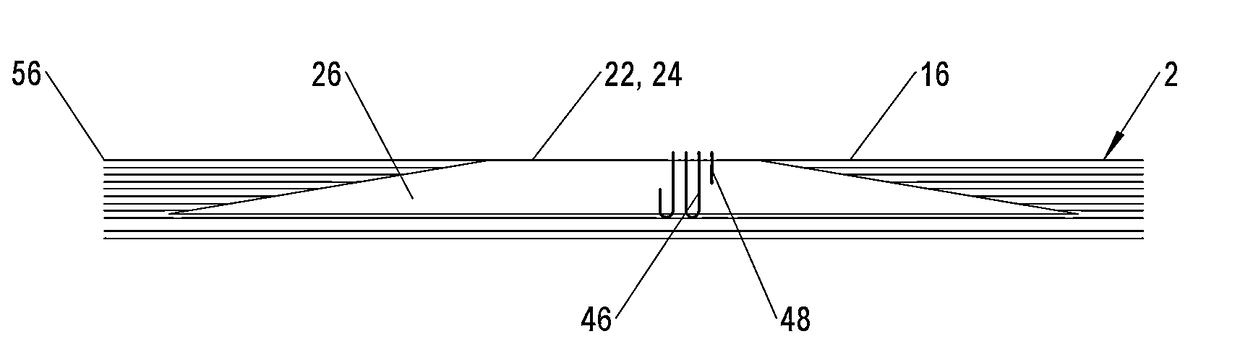

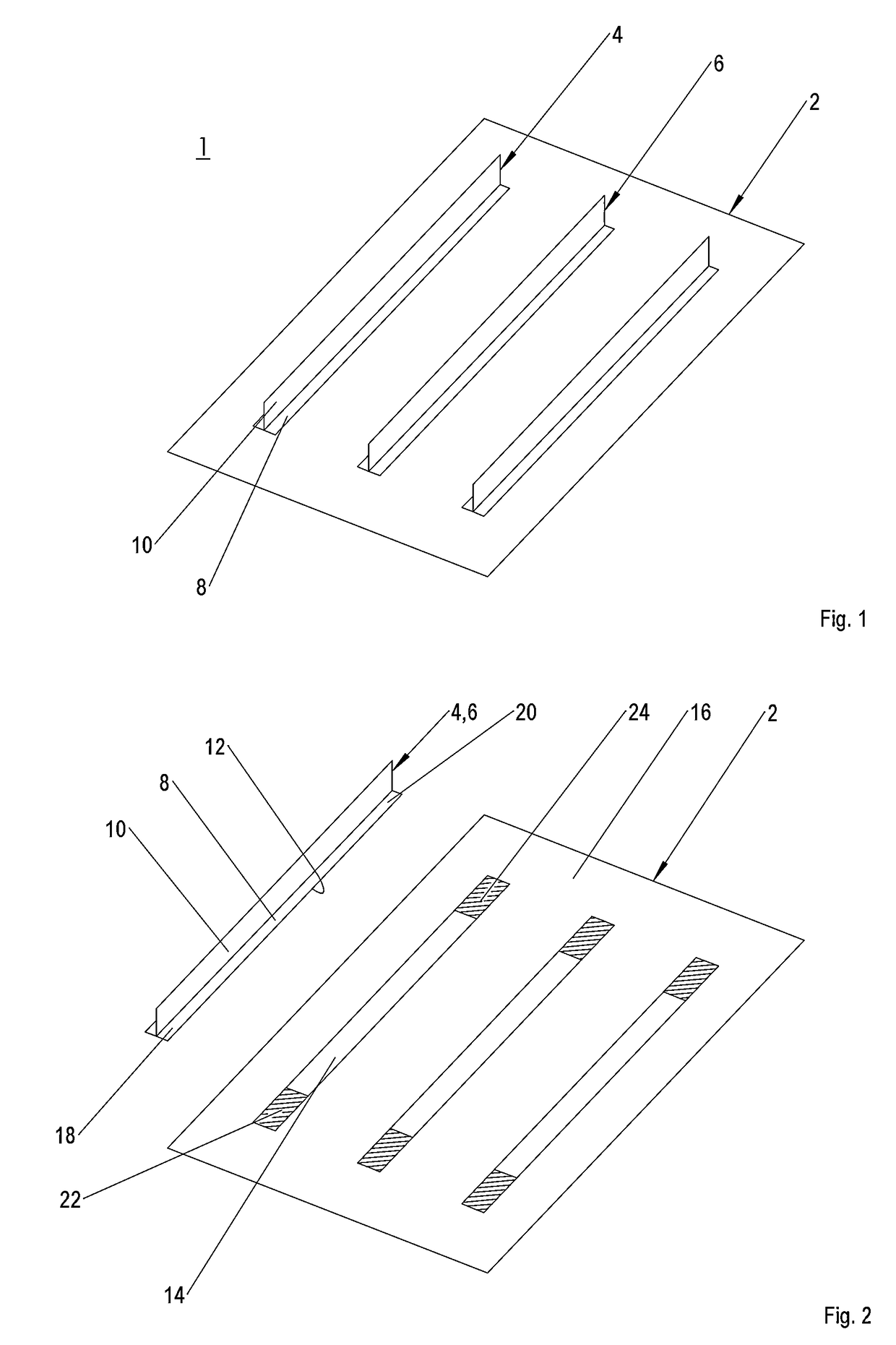

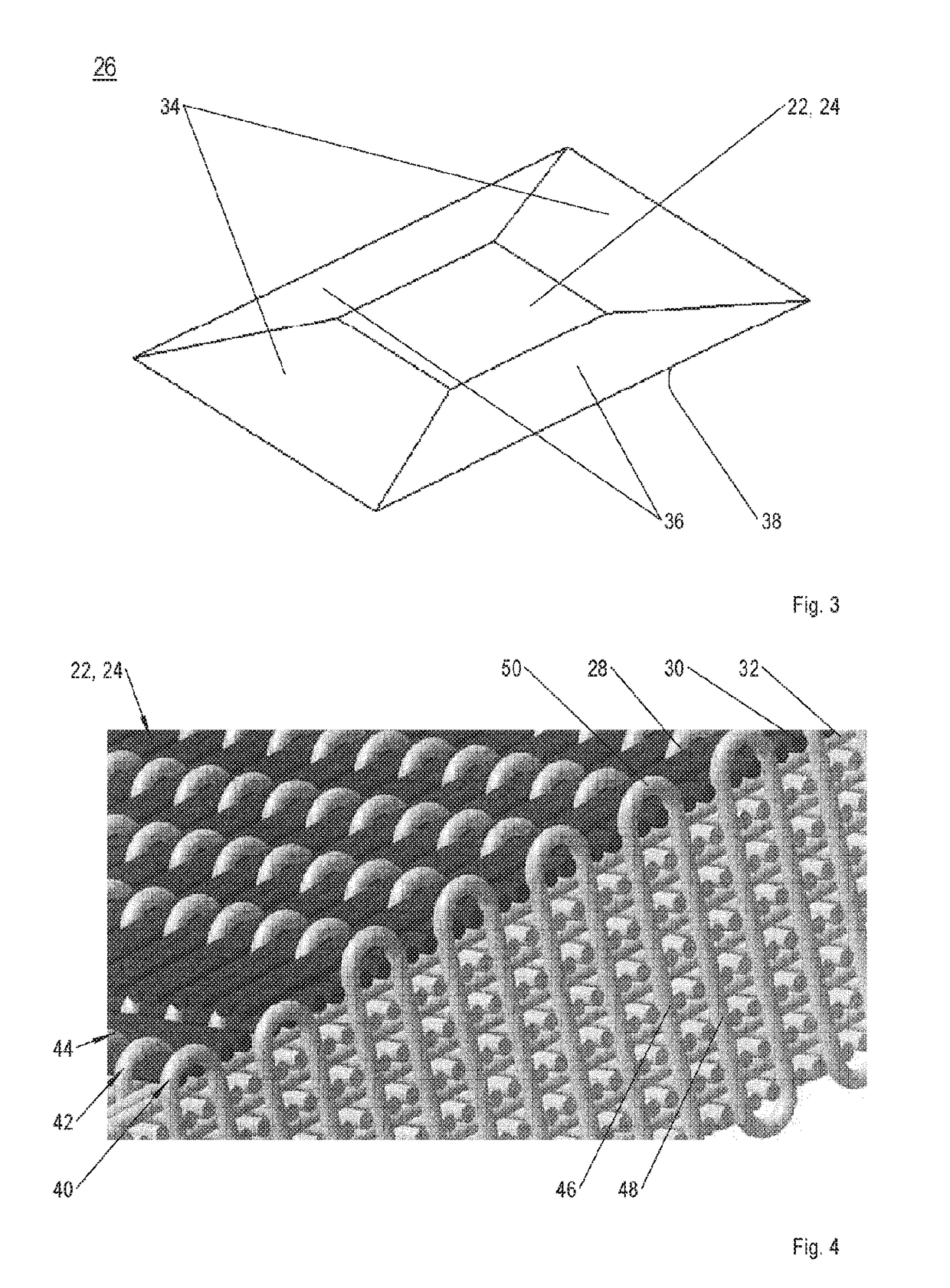

[0032]FIG. 1 shows an inventive fibre composite component 1, with a base element 2, to which a multiplicity of ancillary elements 4, 6 are connected. The fibre composite component 1 is, for example, a shell component, in particular a fuselage shell of an aircraft fuselage, with a skin field, which is stiffened by means of longitudinal stiffeners or stringers, wherein the ancillary elements 4, 6 represent the stringers, and the base element 2 represents the skin field.

[0033]The base element 2 is a shell-type fibre composite element and consists preferably of a multiplicity of fibre webs, which in a laying process such as ATL (Automatic Tape Laying) or FPL (Fibre Placement Laying) have been laid down on a mould surface, not shown, in a plurality of layers and orientations. The fibre webs consist of carbon fibre mats arranged in a thermosetting or thermoplastic resin matrix and are preferably so-called prepregs. Alternatively, however, fibre mats of glass fibres, aramide fibres and sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com