Plastic liner bag with mouth retainer means

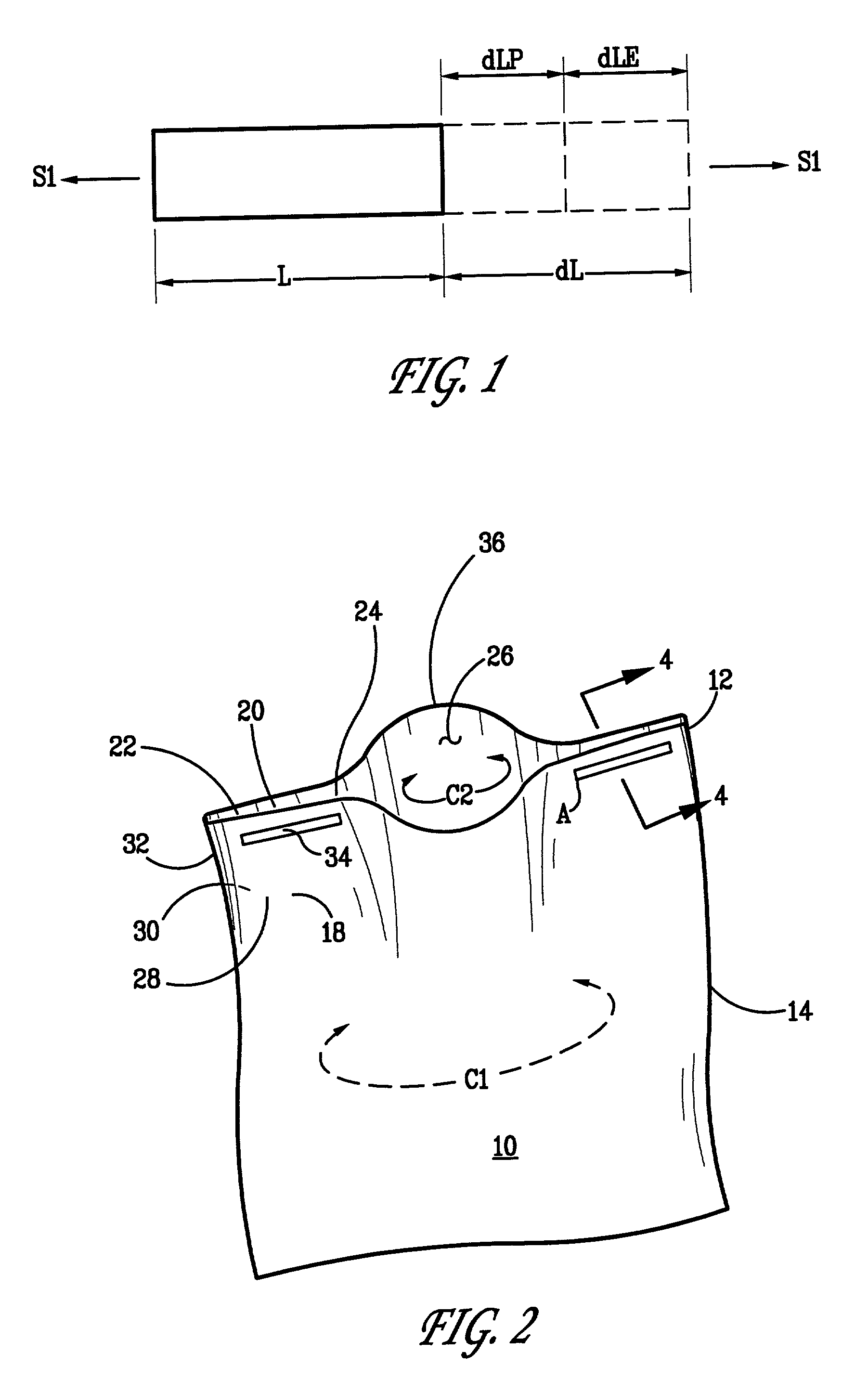

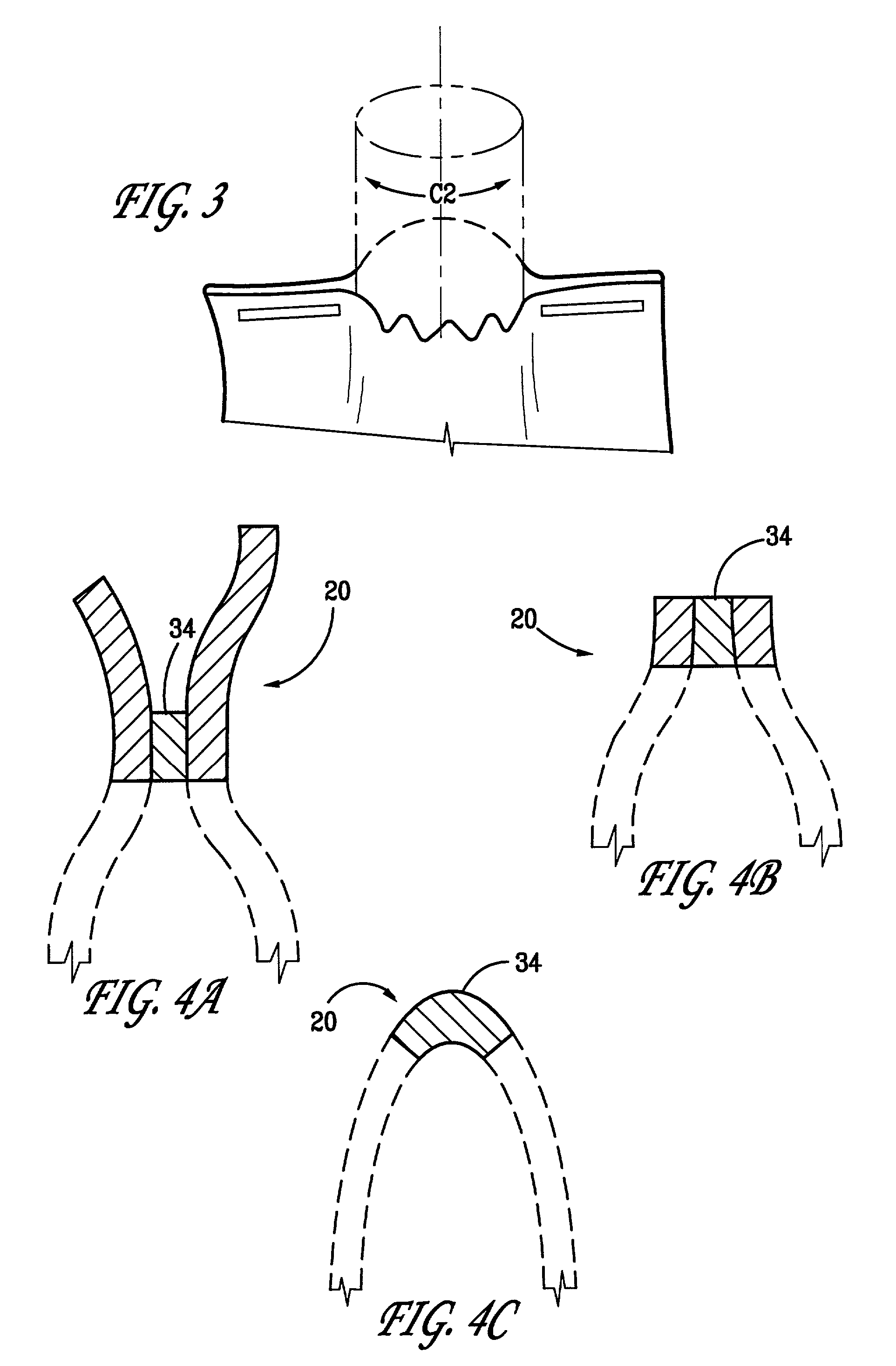

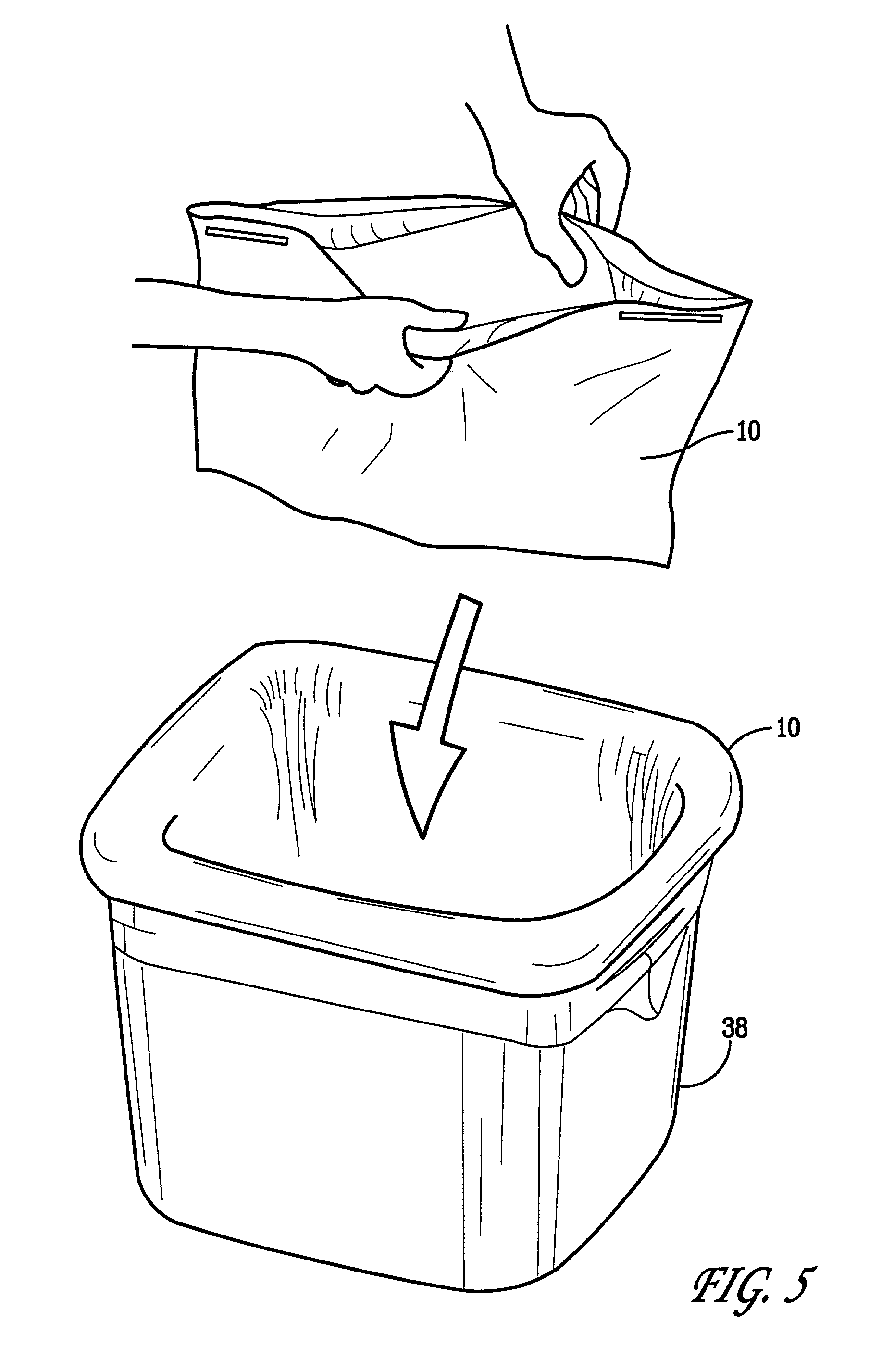

a plastic bag and retainer technology, applied in the field of tubular bags, can solve the problems of plastic bags not being able to reliably remain, the top portion of the bag slipping or falling off, or disengaging from the supporting structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] 1. Background--Plastic Bag Films

[0083] While a bag or liner can be made of virtually any plastic film, the plastic film typically used in a bag or liner construction is not an elastomer, but rather is another plastic such as an olefin plastic. This is especially the case for a bag used for lining a waste or recycling receptacle. Perhaps the most common plastics for bag films at present are ethylene plastics, that is plastics based on polymers of ethylene, or copolymers of ethylene with other monomers, the ethylene being in greatest amount by mass. For example, ethylene plastics for bag films include Low Density Polyethylenes (LDPE), having a density in the range of approximately 0.910 to 0.925 g / cc, Linear Low Density Polyethyenes (LLDPE) having a density in the range of approximately 0.919 to 0.925 g / cc, and High Density Polyethylenes (HDPE) having a density in the range of approximately 0.941 g / cc or greater. Polymer resin blends that include at least one ethylene plastic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com