Motor vehicle tailgate

a tailgate and motor vehicle technology, applied in the field of motor vehicle tailgates, can solve problems such as loss of volume at the back, and achieve the effect of small clearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

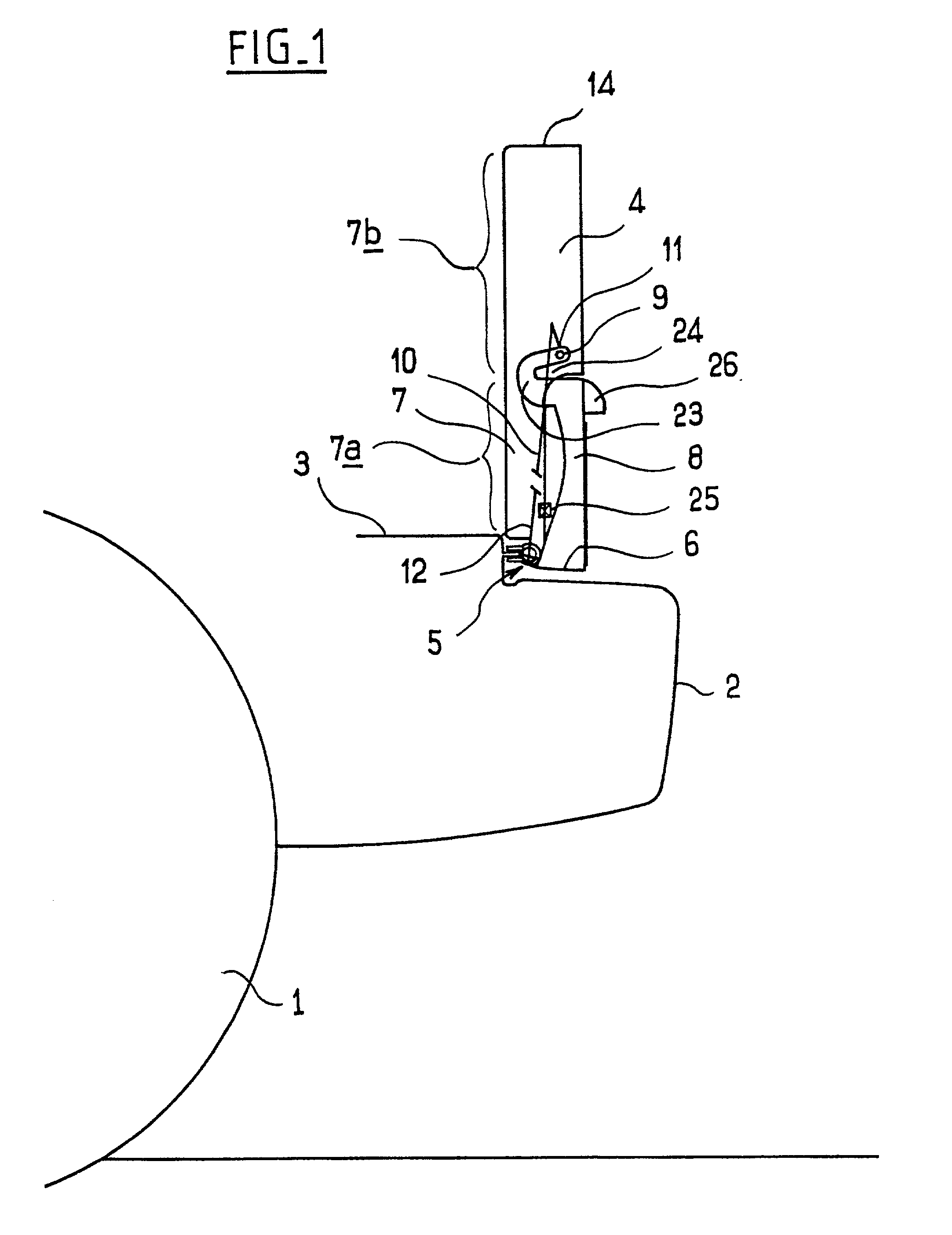

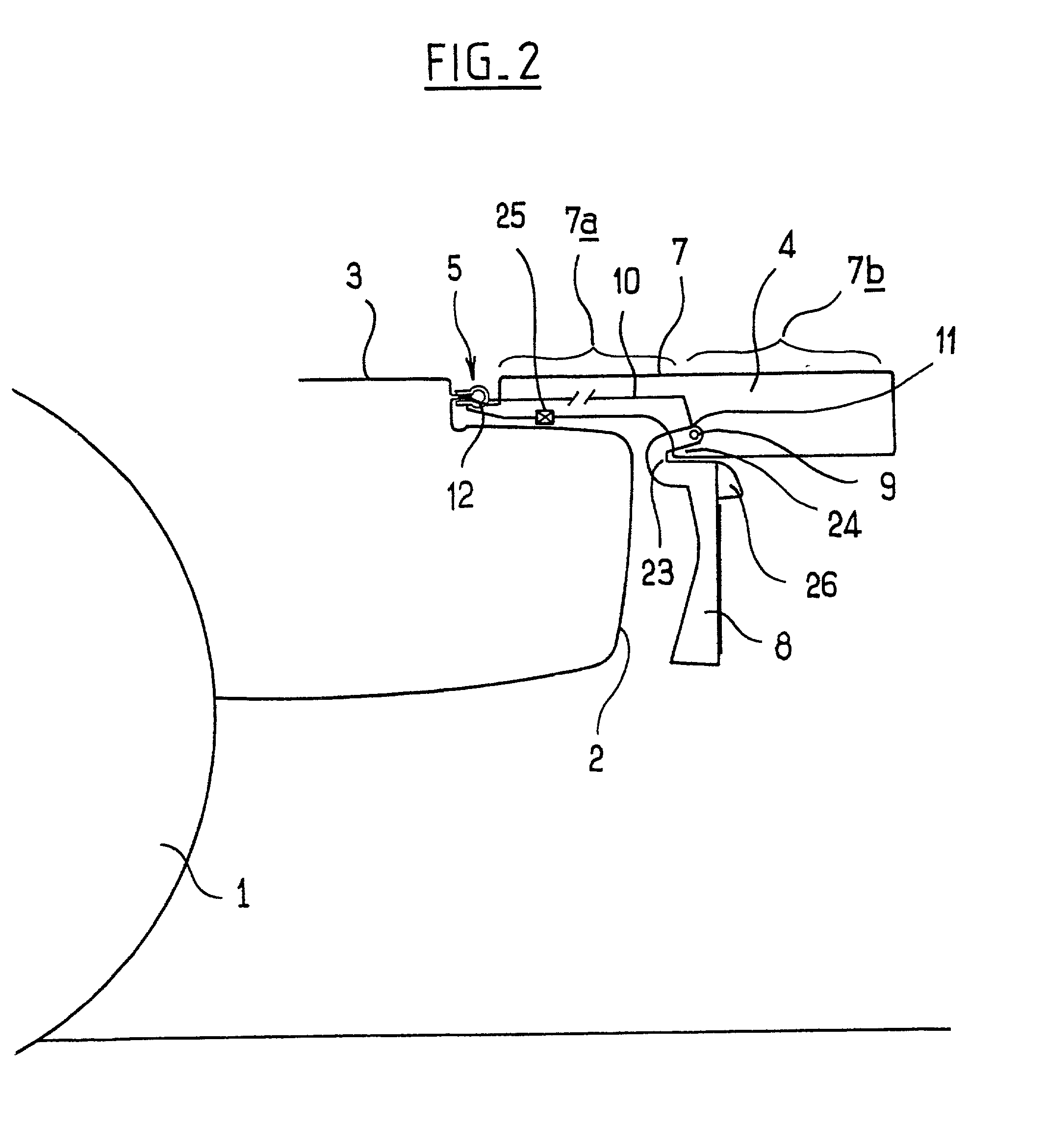

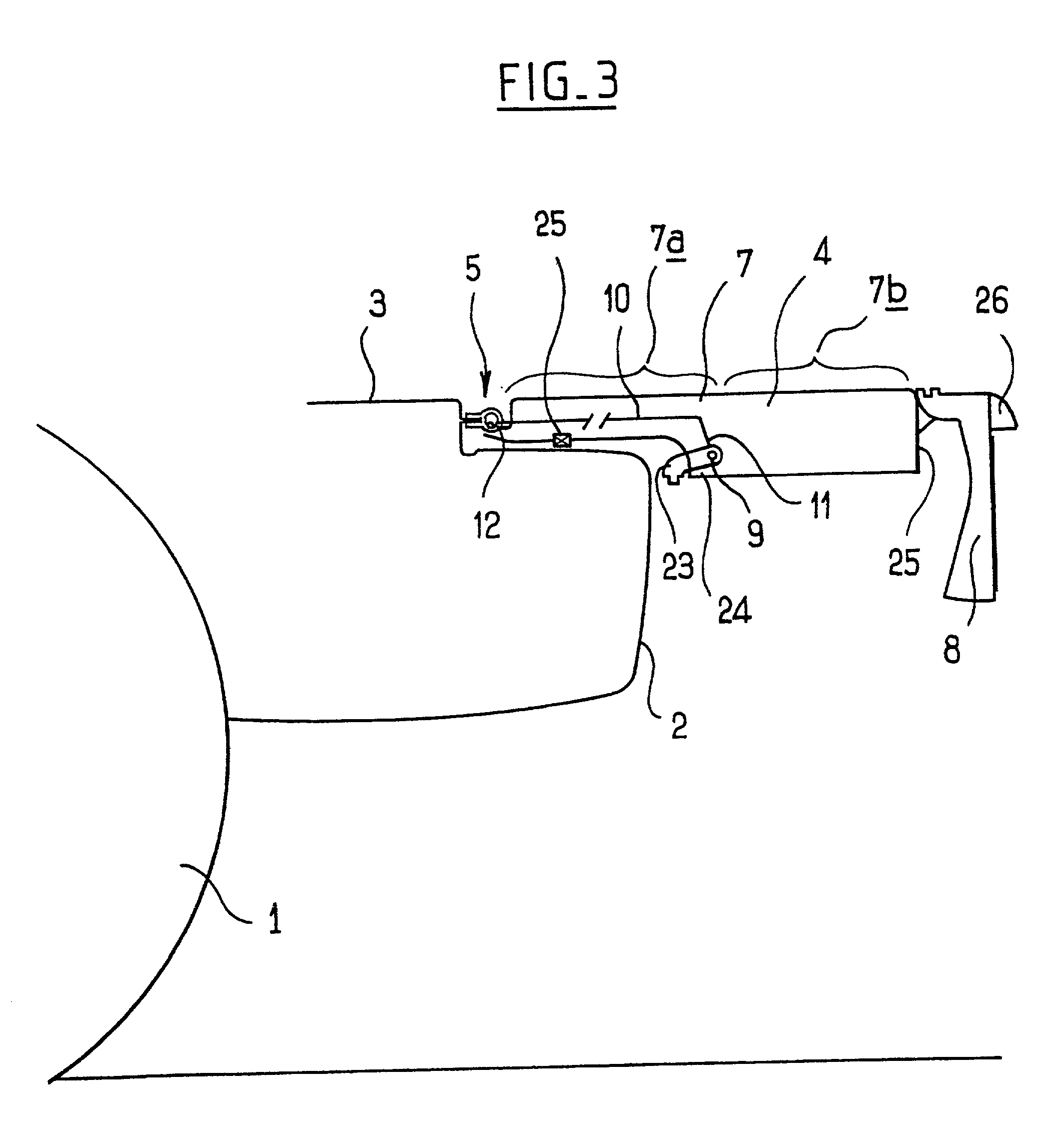

[0032] FIGS. 1, 2, and 3 show the rear left wheel 1 of a vehicle and also its rear bumper 2 and the floor 3 at the back of the vehicle, e.g. in its luggage compartment.

[0033] The back of the vehicle is closed by a tailgate 4 mounted to pivot on the vehicle about hinges 5 situated along the bottom horizontal edge 6 of the tailgate.

[0034] The tailgate 4 is shown diagrammatically in FIGS. 1 to 3. Its outside shape is shown in greater detail in FIG. 4.

[0035] The tailgate is constituted by an inside panel 7 which, in the terminology of this specification, constitutes the "main" panel of the tailgate.

[0036] This inside panel 7 extends over the entire surface area of the tailgate from its hinges to its top horizontal edge remote from the hinges. It forms the entire inside face of the tailgate.

[0037] The main panel 7 has a portion 7a close to the hinges that is of reduced thickness and an additional portion 7b remote from the hinges of thickness that corresponds to the total thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com