Induction-type position measuring apparatus

a position measuring and induction-type technology, applied in the direction of electrical/magnetic position measurement, instruments, and converting sensor output electrical/magnetically, etc., can solve the problems of significant measurement errors and offset values experiencing non-negligible variation amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

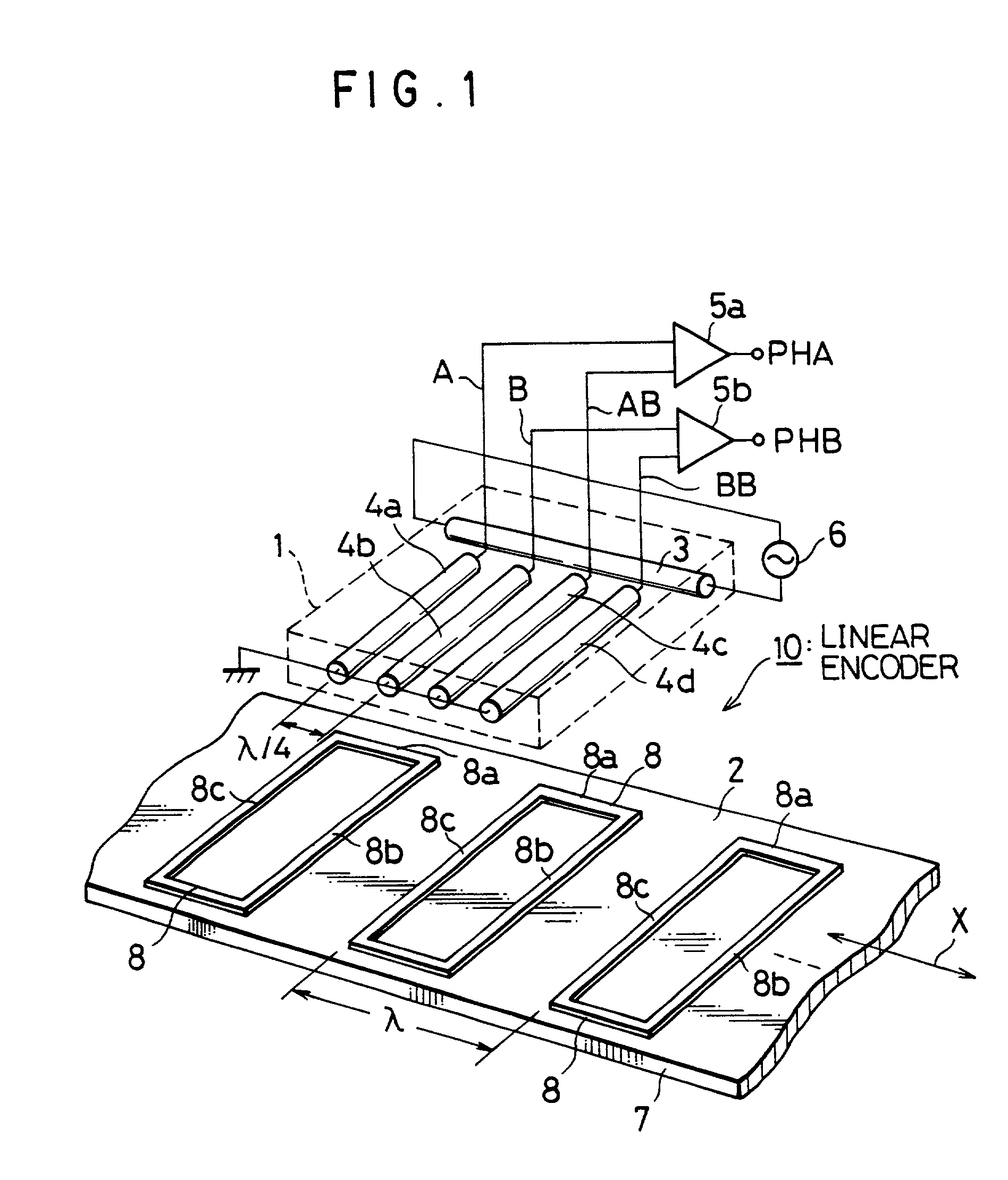

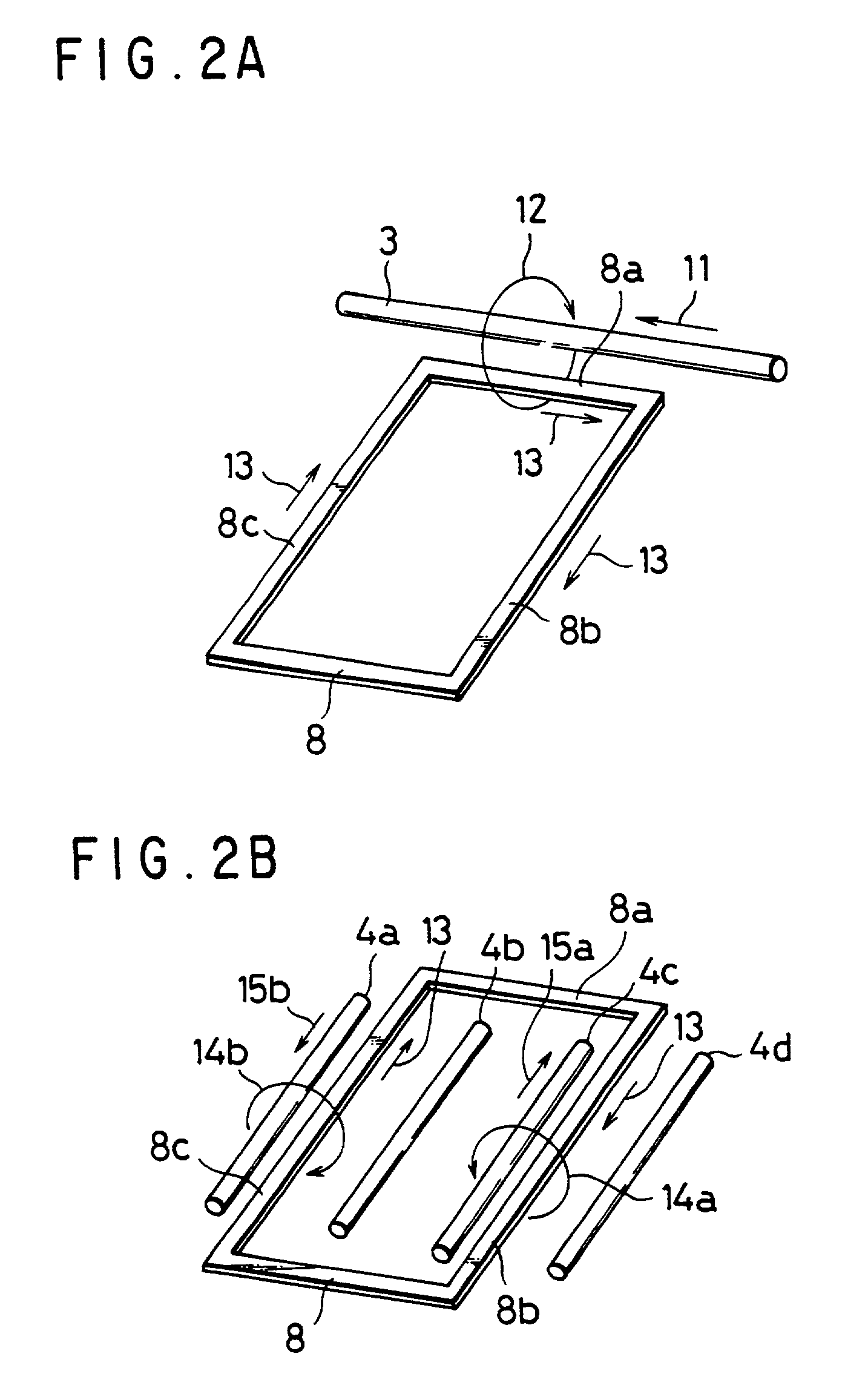

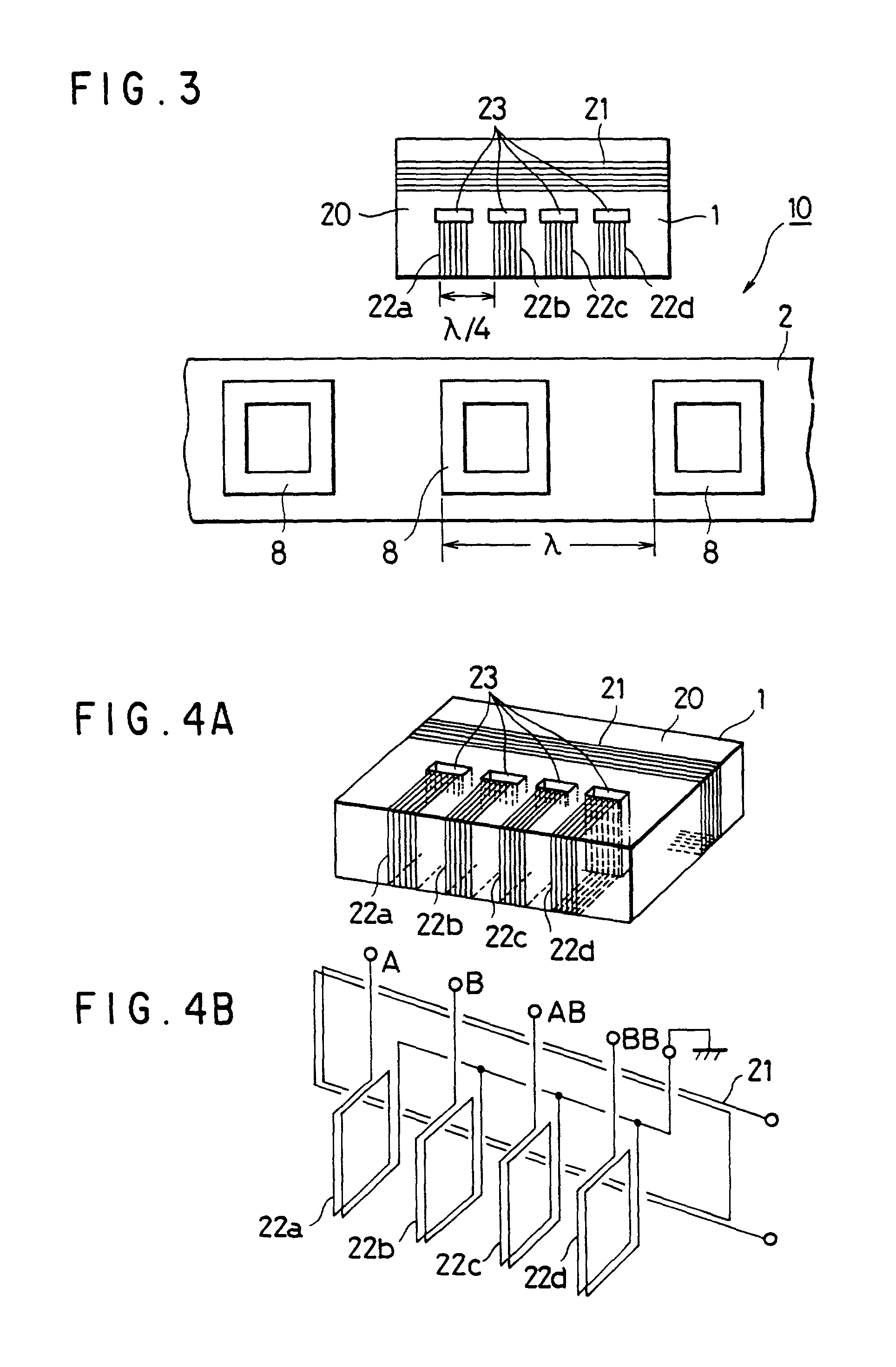

[0039] Referring now to FIG. 1, there is illustrated in perspective view a principal configuration of an electromagnetic linear encoder 10 in accordance with one embodiment incorporating the first principle of the invention. As shown herein, the encoder 10 includes in combination a sensor 1 (as a first member), and a scale 2 (as a second member). The sensor 1 and scale 2 are disposed opposing each other with a predetermined distance or gap defined between them. The scale 2 is relatively movable reciprocally along a preset measurement axis X, which is set in the longitudinal direction of the scale 2. The sensor 1 includes a drive wire 3 having a preselected length, which extends in the measurement axis X. The sensor 1 also includes parallel spaced-apart detection wires 4 that lie perpendicular to the drive wire 3 in the same plane. These wires act as detection wires, and are illustratively formed from four wires 4a-4d as one unitary group or set. The layout interval or pitch between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com