Valve control device of internal combustion engine

a control device and internal combustion engine technology, applied in the direction of valve arrangements, machines/engines, mechanical equipment, etc., can solve the problems of difficult to obtain difficult to achieve the desired engine performance, and improved engine fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

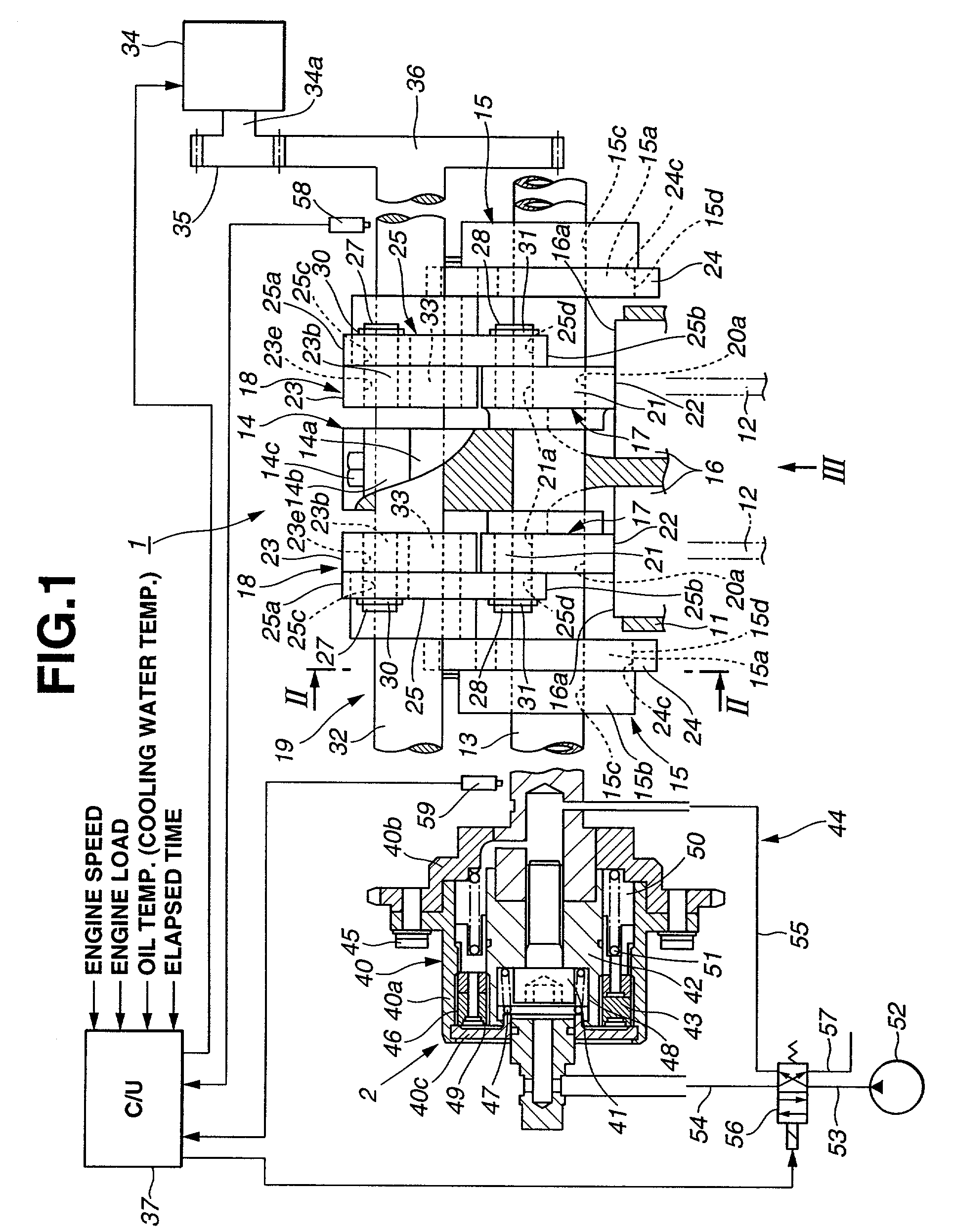

[0041] The valve control device of the first embodiment comprises generally a first variable valve actuating mechanism 1 that varies or controls the operating angular range of the intake valves 12, a second variable valve actuating mechanism 2 that varies or controls the center angle of the operating angular range of the intake valves 12 and a control unit 37 that controls the first and second variable valve actuating mechanism 1 and 2 in accordance with operation condition of the engine. The control unit 37 comprises a micro-computer including CPU, RAM, ROM and input and output interfaces.

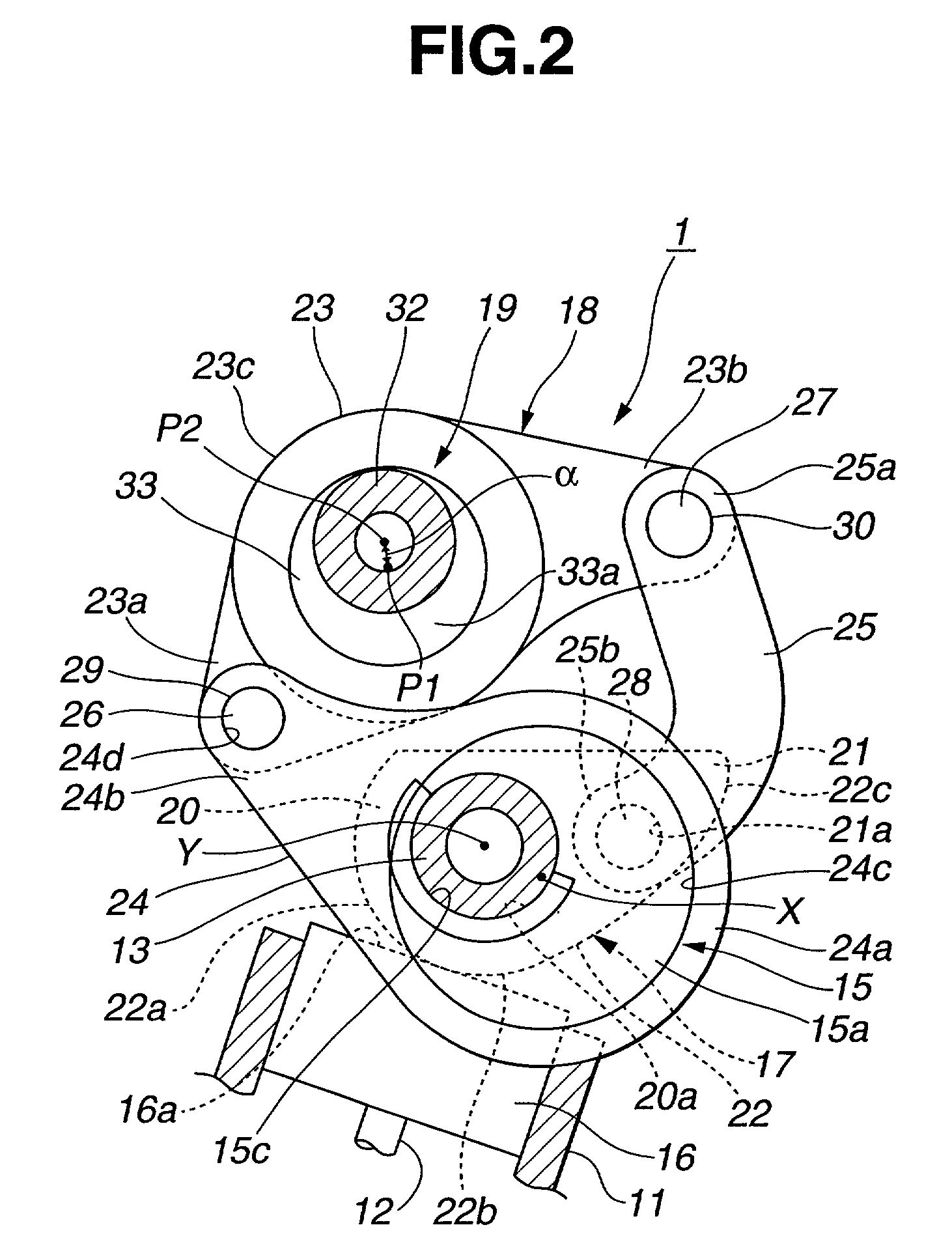

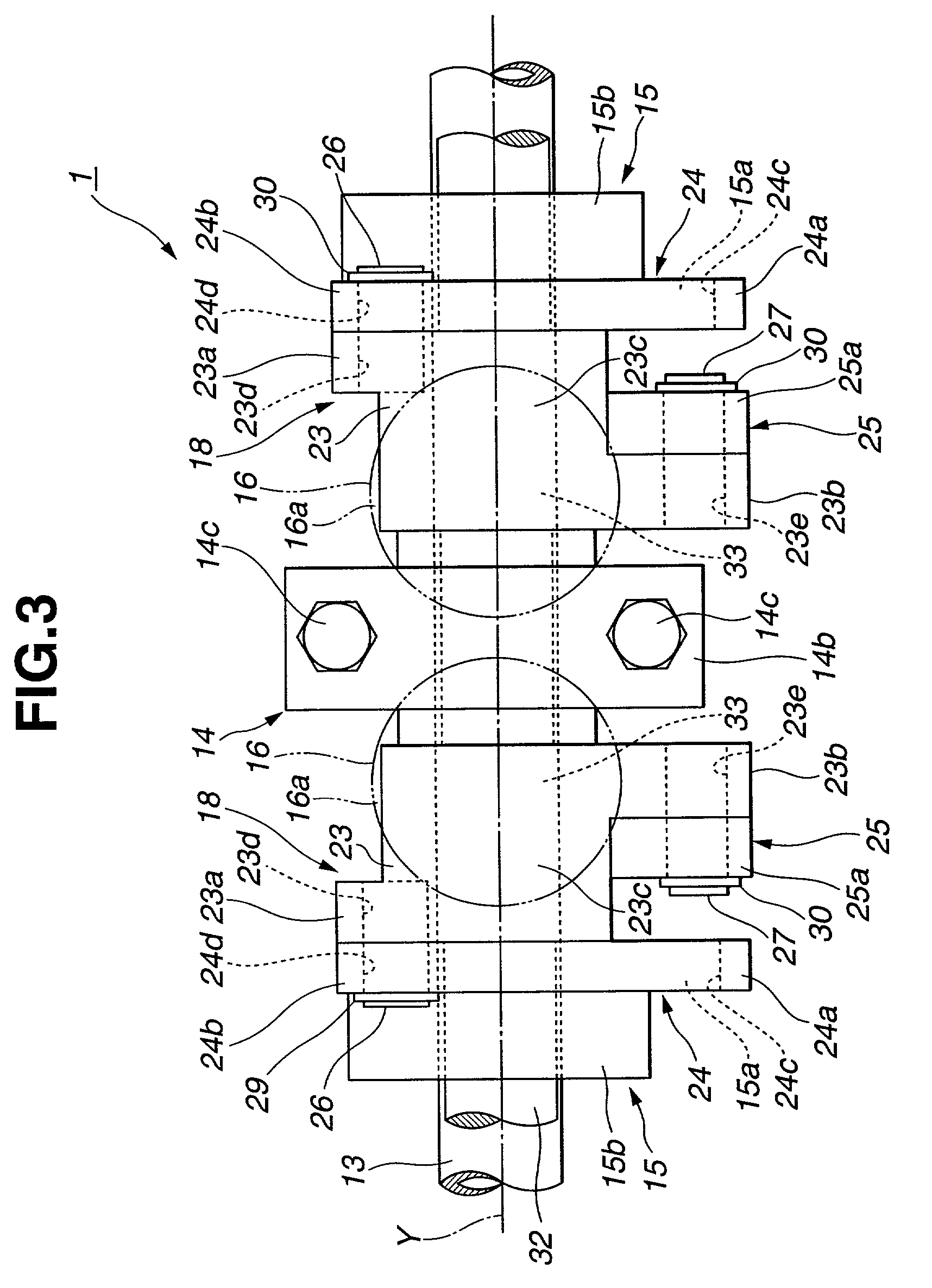

[0042] As is seen from FIGS. 1 to 3, the first variable valve actuating mechanism 1 generally comprises a hollow drive shaft 13 that is rotatably held by bearings 14 (only one is shown) mounted on the cylinder head 11, two eccentric drive cams 15 that are tightly disposed on the drive shaft 13, two swing cams 17 that are swingably or rotatably disposed on the drive shaft 13 and slidably contactabl...

second embodiment

[0089] FIGS. 12 to 14 show an intake system of an internal combustion engine to which the second embodiment is practically applied. As will be described in detail in the following, in this intake system, there is arranged a swirl control valve 105 that enhances a mixture flow in the intake system.

[0090] As is shown in FIG. 12, intake air is led into a combustion chamber 104 through an intake manifold 102 and an intake port 103. As is seen from FIG. 14, the intake port 103 is branched into two intake ports 103a and 103b each having an electromagnetically actuated intake valve 12 (see FIG. 12). That is, upon lifting of the intake valves 12, intake air is led into the combustion chamber 104.

[0091] As is seen from FIG. 12, the swirl control valve 105 is installed in the manifold near the intake port 103. As is seen from FIGS. 13 and 14, the swirl control valve 105 has a cut 105a at a portion facing the intake port 103a. Accordingly, when the swirl control valve 105 assumes its close pos...

third embodiment

[0098] The valve control device of the third embodiment comprises generally a first variable valve actuating mechanism 1' that continuously varies the operating angular range (or valve lift degree) of the intake valves 12 and a second variable valve actuating mechanism 2' that continuously varies the center angle of the operating angular range and a control unit 37 that controls the first and second variable valve actuating mechanisms 1' and 2' in accordance with operation condition of the engine.

[0099] In the third embodiment, a hydraulically controlled step motor 34' is used. Between the step motor 34' and the oil pump 52, there is installed a solenoid type switching valve 60 that is controlled by the control unit 37. That is, based on instruction signal from the control unit 37, the control shaft 32 is rotated stepwise changing the angular position thereof.

[0100] That is, based on the engine speed, load, oil temperature, elapsed time from engine start, etc., the control unit 37 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com