Natural feathered fiber insulator

a technology of natural feather fiber and insulator, which is applied in the directions of heat-proofing, yarn, transportation and packaging, etc., can solve the problems of increasing the aperture rate of the insulator, incineration or burying of the conventional insulator for construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

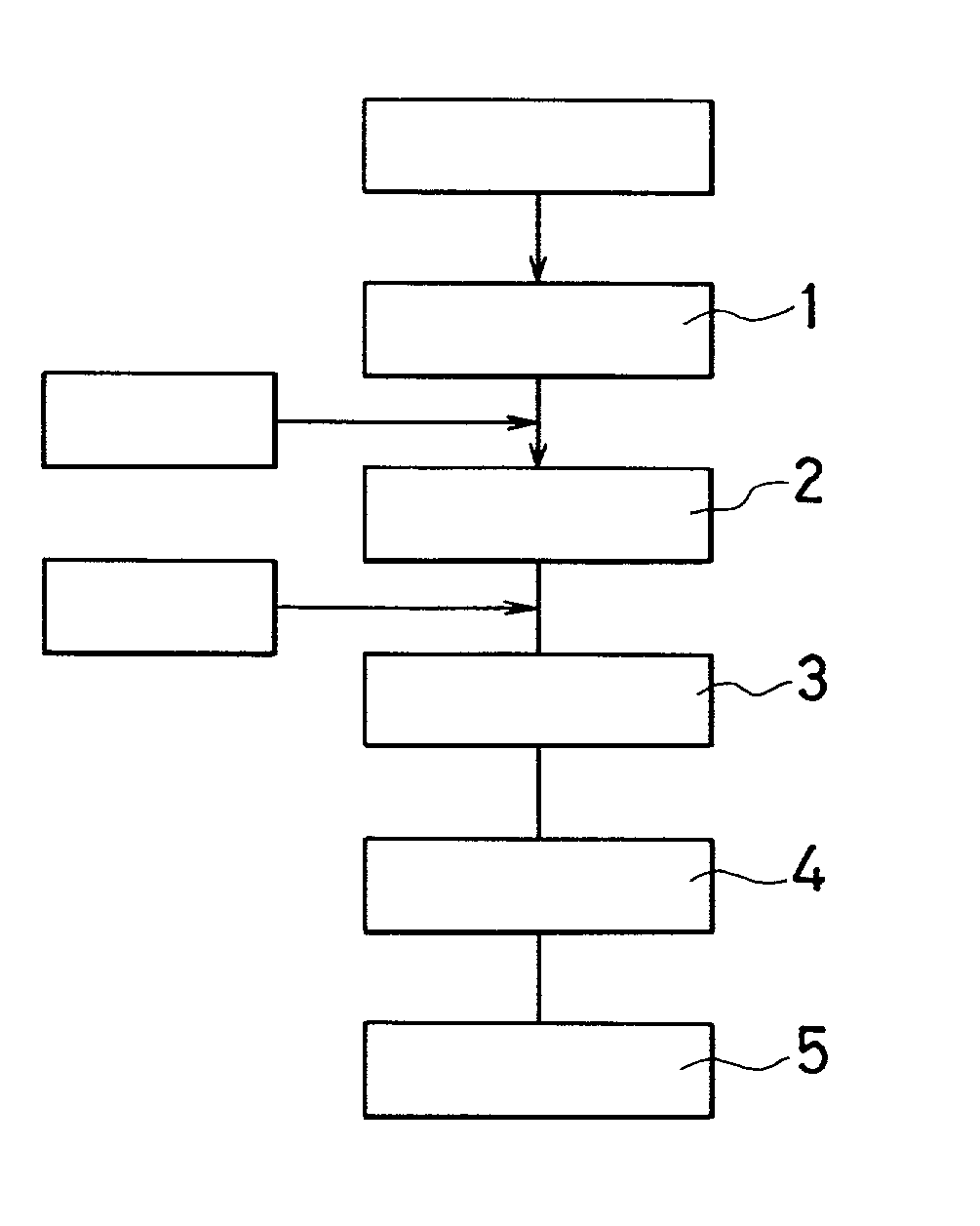

[0013] Now, embodiment of the present invention will be described based on the attached drawings. FIG. 1 shown the manufacturing process of natural feathered fiber insulator, and first, natural feathers, for instance bird plumes used for a down quilt are degreased and washed with alcohol 1. Then, after drying, they are processed into fibers of about 10 mm in length by a cutter having a screw form blade 2.

[0014] 1 to 99 weight % of feathered fiber obtained by the aforementioned fiber shape processing 2 and 1 to 99 weight % of synthetic fiber as binder are compounded, and mixed so that both fibers become uniform 3. Feathered fiber 3 compounding rate is preferable 50 to 90%, however, it may differ according to the use object of the insulator, and is not limited.

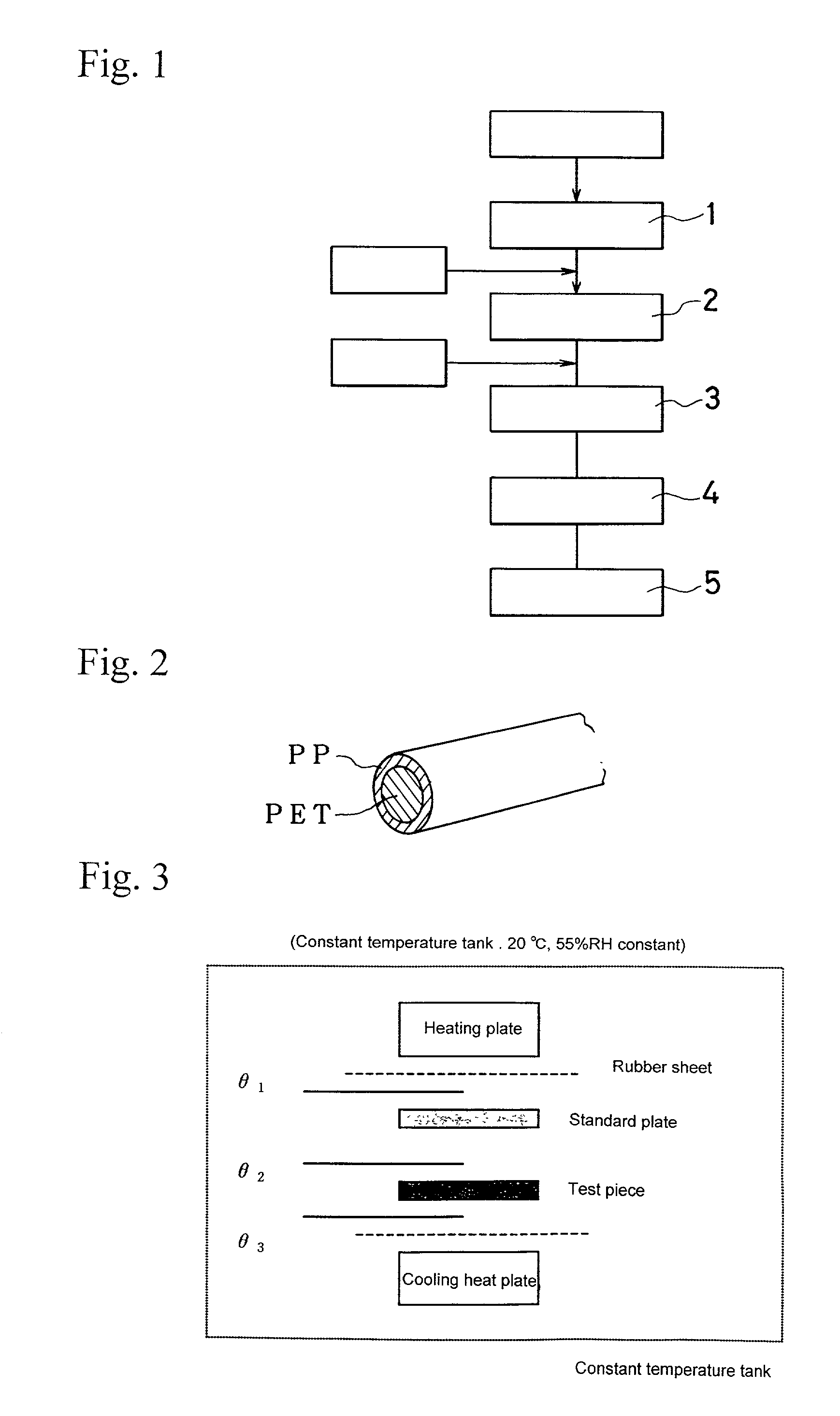

[0015] Concerning synthetic fiber as binder, a core sheath composite fiber wherein the sheath portion is made of low melting point olefin and the core portion is made of high melting point synthetic resin, for example, a core sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight % | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com