Volume reducing agents for expanded polystyrene, methods and apparatus for processing expanded polystyrene using the same

a technology of volume reducing agent and polystyrene, which is applied in the direction of plastic recycling, recycling and recovery technologies, etc., can solve the problems of large amount of waste, harmful gases, and problems such as disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

>

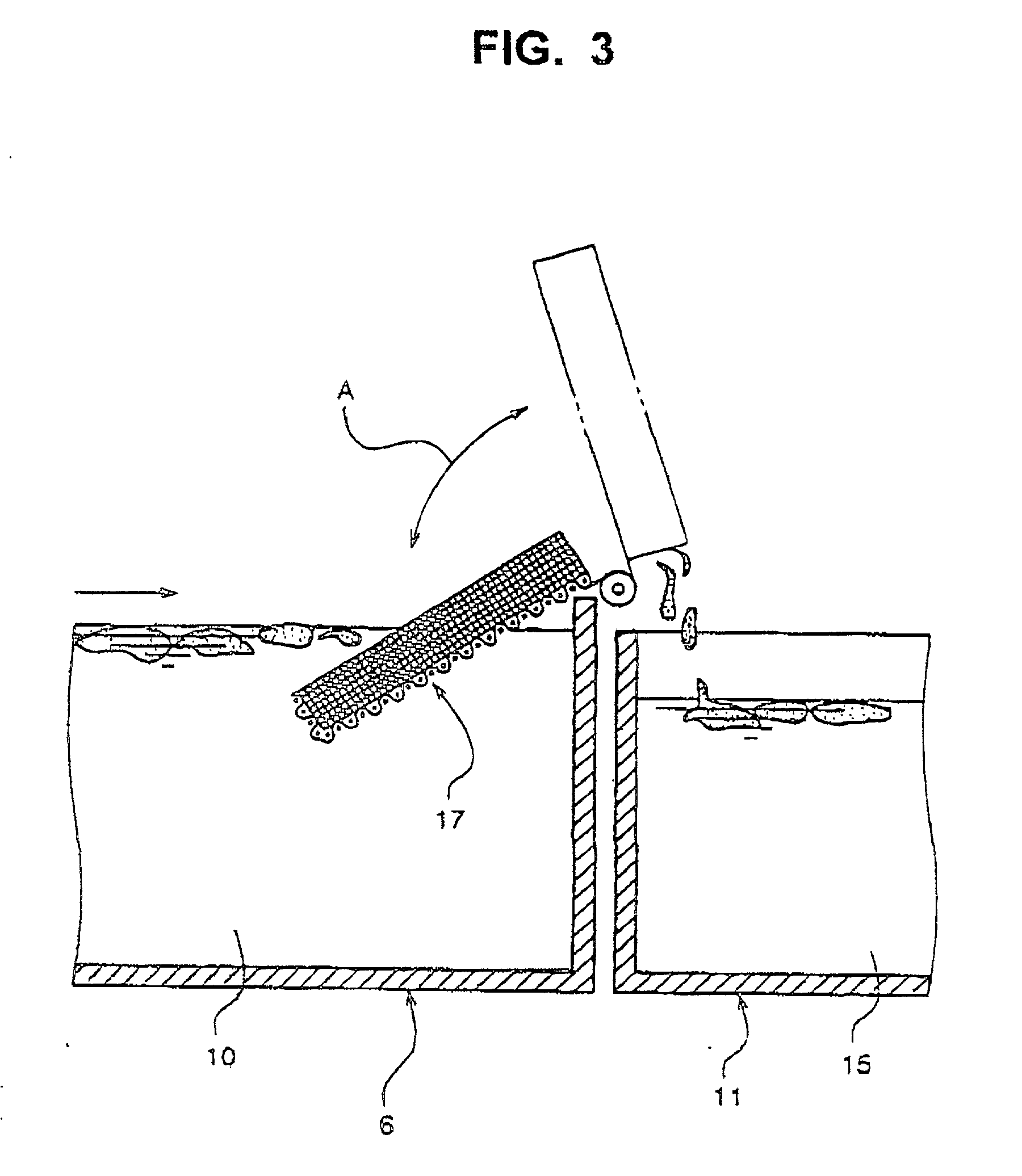

[0044] Referring to FIG. 3, it shows the simplified embodiment of the entrapping device used in the present apparatus.

[0045] The main vessel numbered 6 is filled with the volume reducing agent 10, the numeral 7 being given to the neutralization vessel for underflowing the neutralizing solution. EPS 1 reduced in volume which is floating along the arrow direction in the bath 6 may be picked up by a meshed sieve 17 which intermittently swings in the directions shown by arrow A, and then successively thrown into the vessel 7. The details on the remainder of the configuration of the process apparatus 5 are arranged in the same manner as shown in FIG. 2.

[0046] FIG. 4 shows another modified and more developed embodiment of the entrapping device used in the present apparatus.

[0047] The entrapping device comprises an aspiration device 18 for sucking EPS 1 reduced in volume which is floating along the arrow direction in the bath 6, the device 18 being capable of delivering sucked EPS 1 from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com