Wavelength multiplexed quantitative differential interference contrast microscopy

a contrast microscope and multi-wavelength technology, applied in the field of differential interference contrast microscope systems, can solve the problems of small loss in precision, large amount of data generated by the wai microscope, and significant differences between the microscopes, and achieve rapid, robust, and robust measurement of the slope of the sample surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Reference is now made in detail to a specific embodiment of the present invention, which illustrates the best mode presently contemplated by the inventor for practicing the invention. Alternative embodiments are also briefly described as applicable.

[0046] 1. DIC Background.

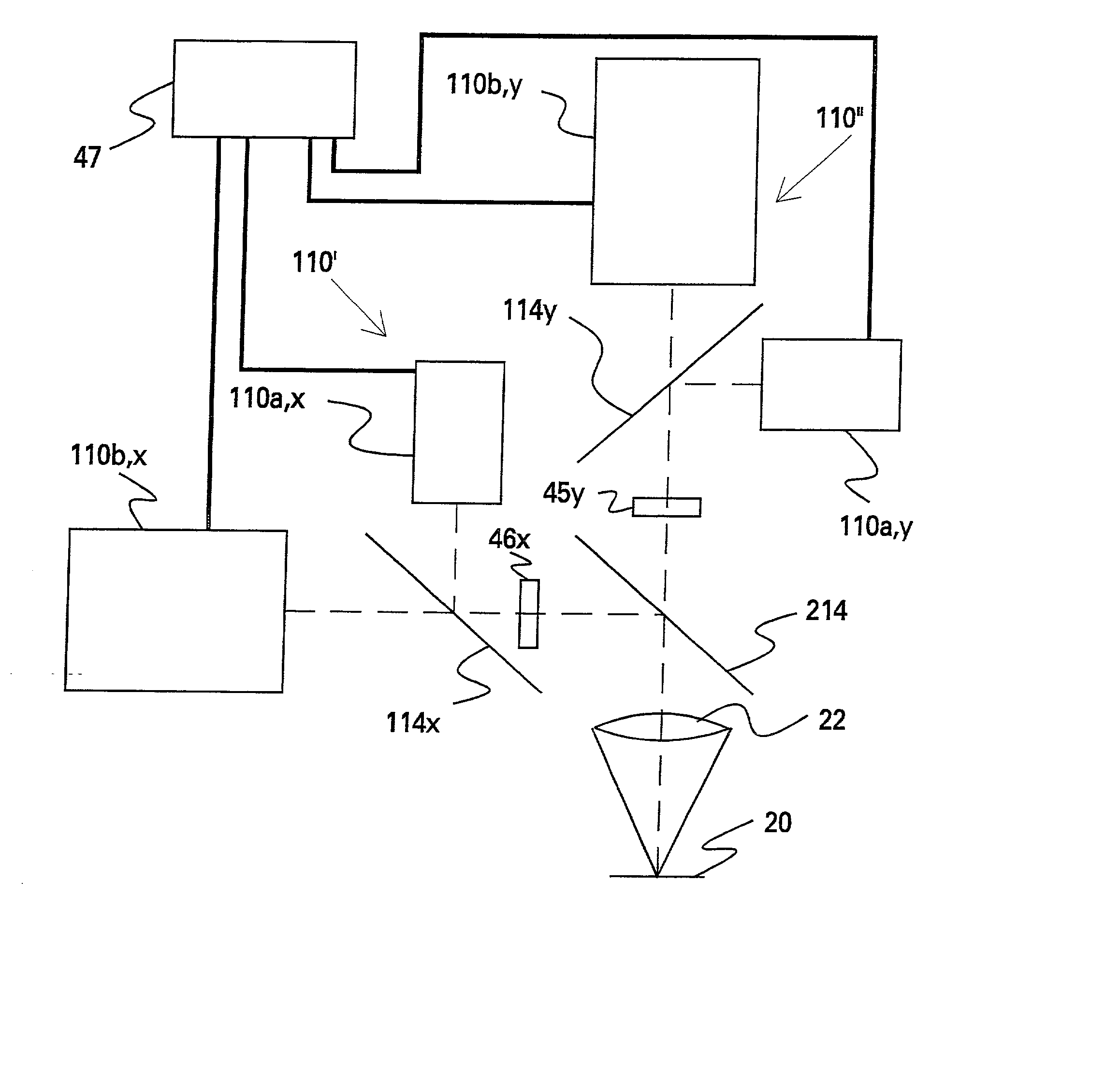

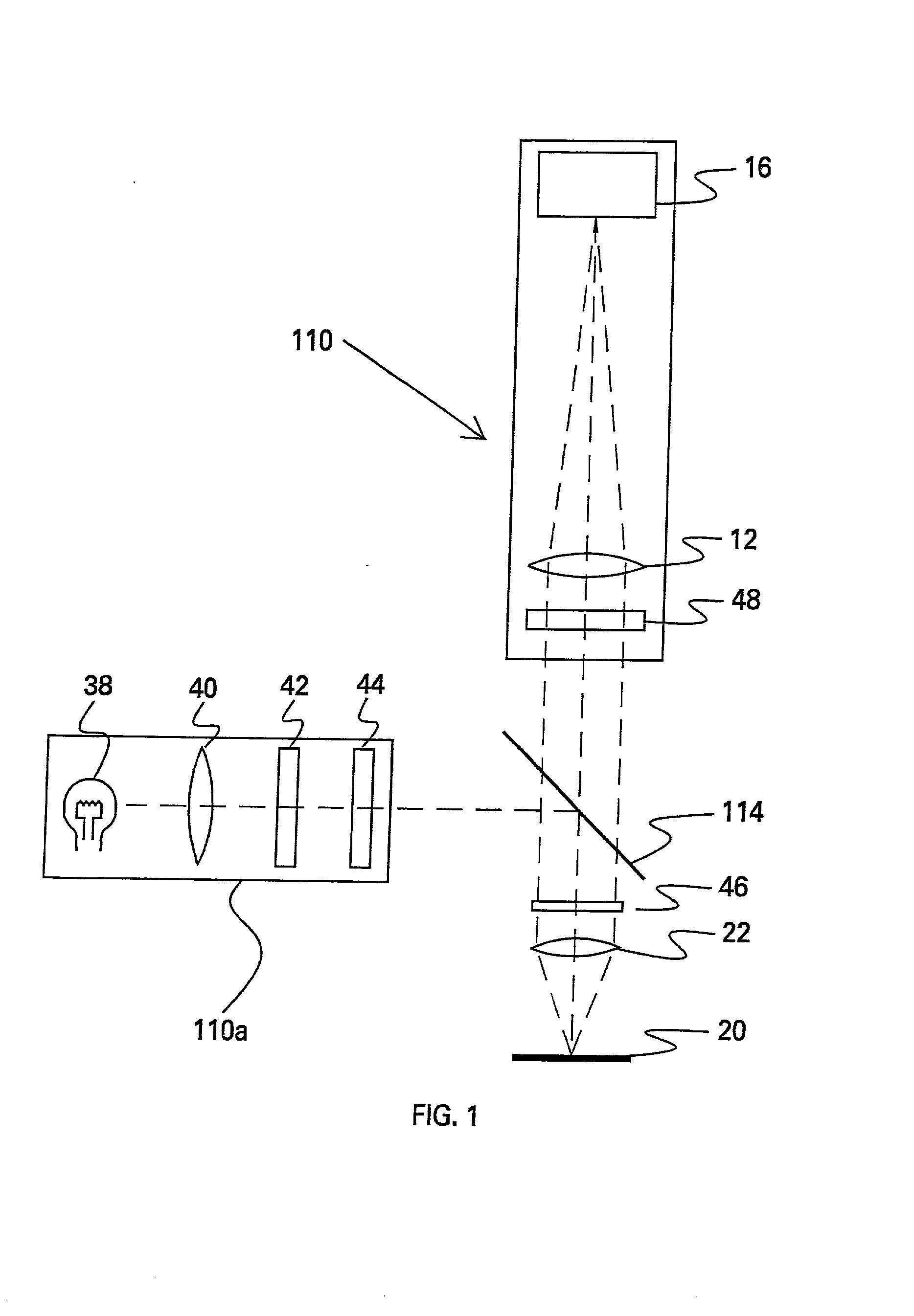

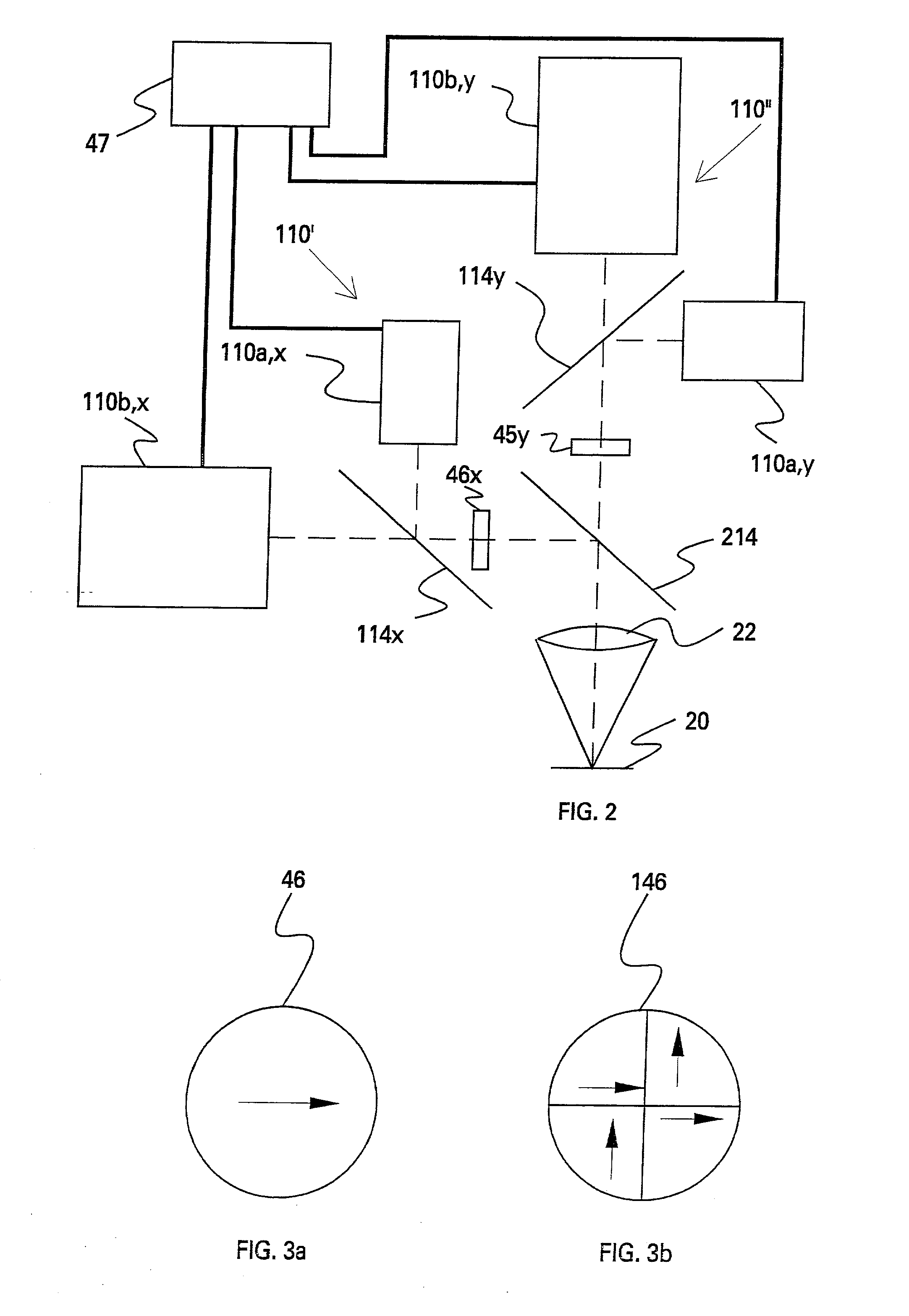

[0047] The advantage of DIC measurement methods over typical interferometric microscopes is due to common path design of the interferometer and resultant insensitivity to vibration and other environmental effects. However, the data obtained by DIC measurements represents surface slope rather than surface height. Additionally, it is necessary to measure slope in two directions and integrate to permit the unambiguous determination of height a general surface. It is preferable that the slope data are in two orthogonal directions; however, the requirement is that the directions are not parallel.

[0048] Hong et al, in section 3 of their above-referenced paper, describe how to obtain height profiles in one directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com