Processes for paper manufacture, useful for incorporating paper waste requiring a basic treatment into paper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

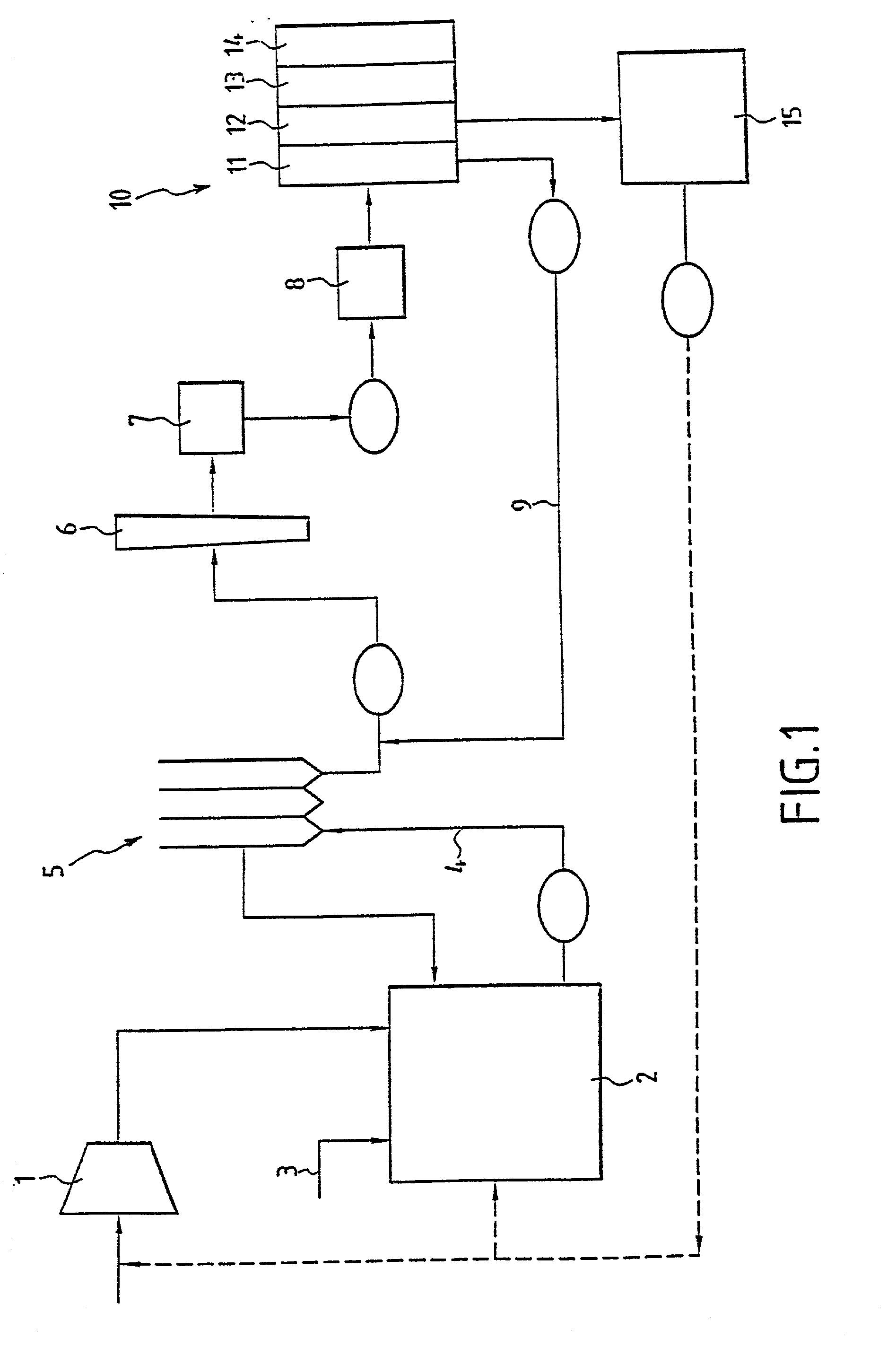

Embodiment Construction

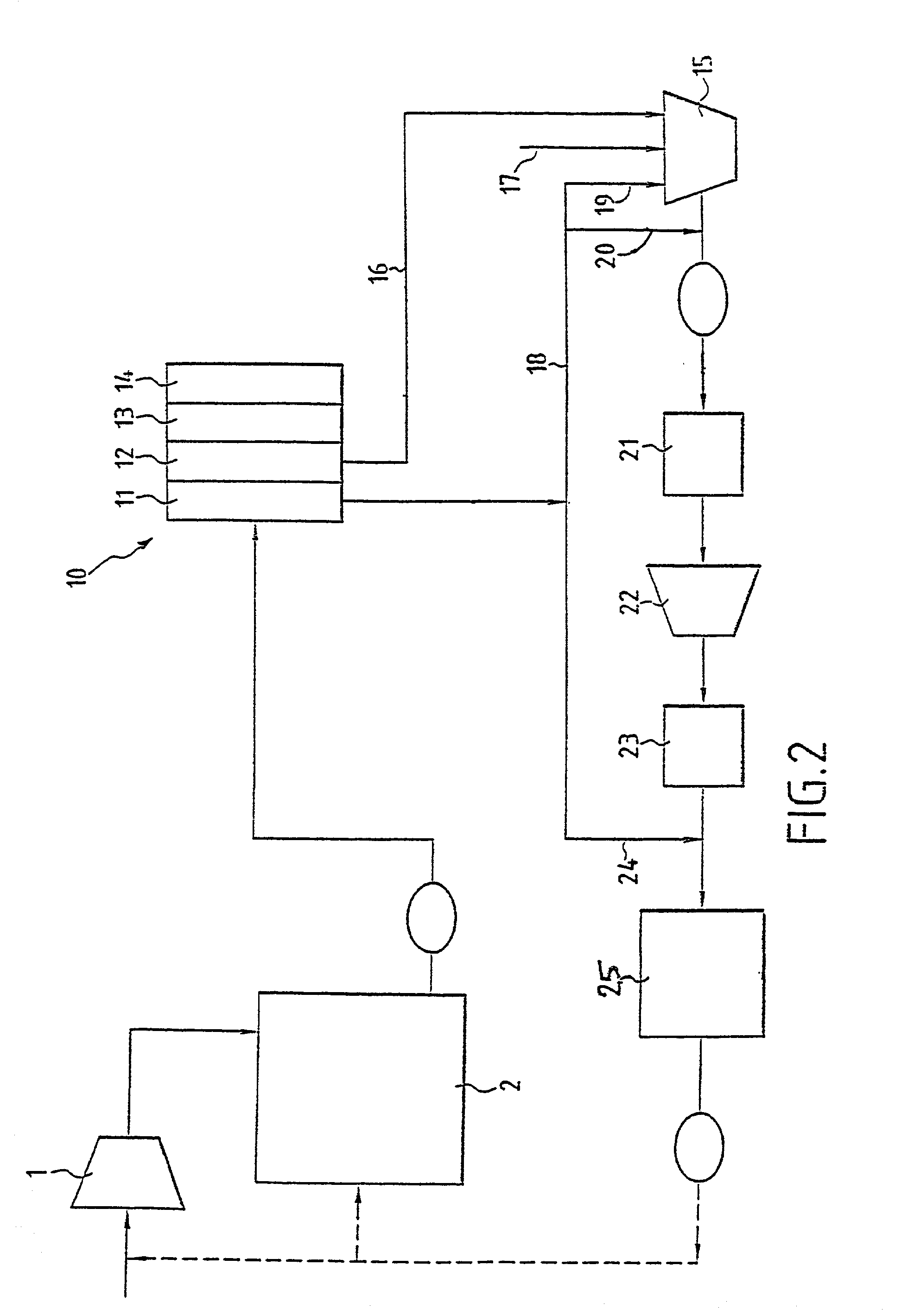

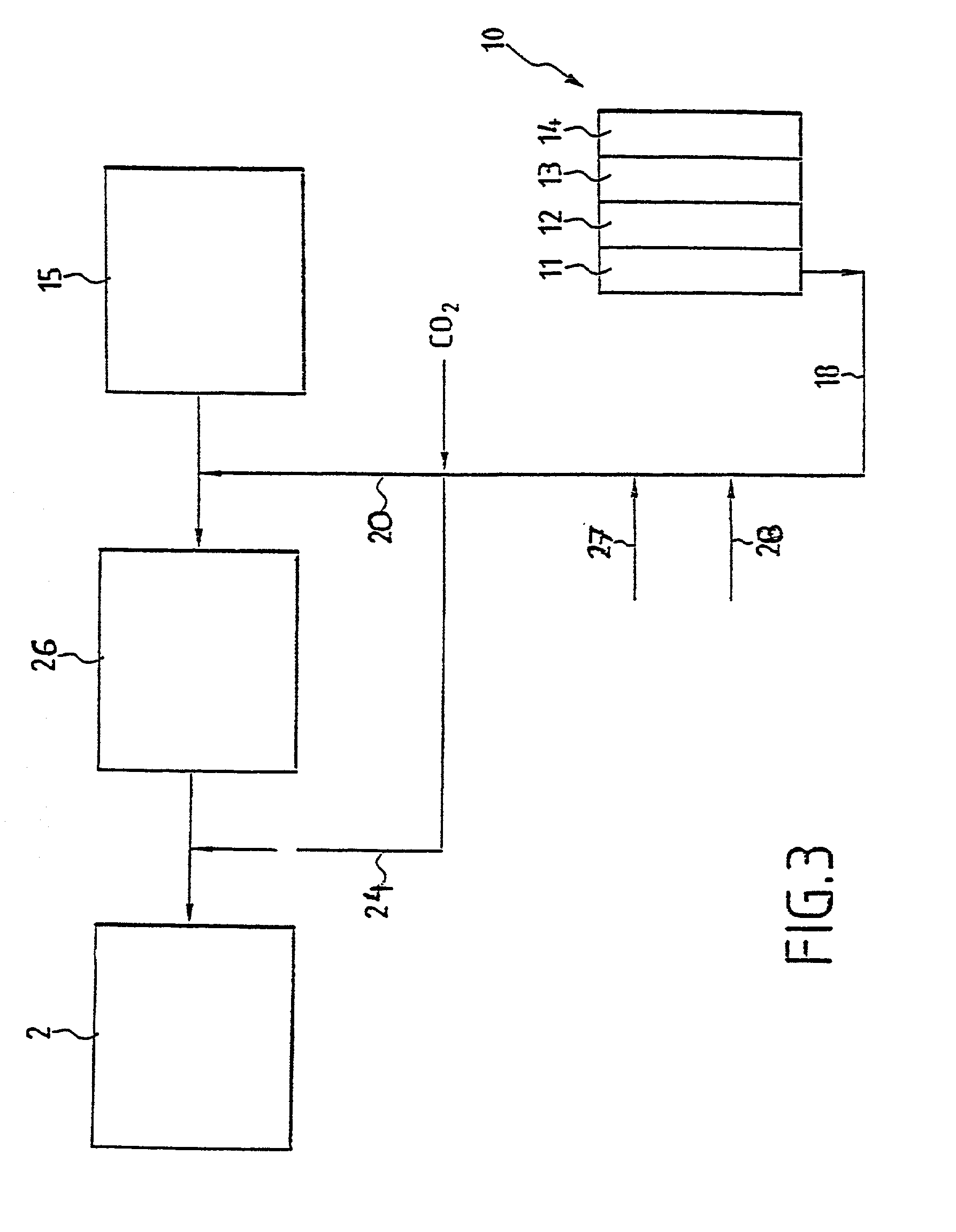

[0125] In these examples, the broke is of the WS (wet strength) type (during the tests reported here, injection of carbon dioxide into the white water have not been carried out).

[0126] The objective of the tests were to compare the locations of the carbon dioxide injections into the broke circuit and to evaluate the advantage of substituting sulfuric acid with carbon dioxide according to the process of the invention.

[0127] In this particular case, the broke treatment has, in the deflaking step, a loop circuit in which the broke is pumpted into the tank 25 and reinjected between 21 and 22 so as to obtain the satisfactory end product; it is then discharged into 2, according to FIG. 2.

[0128] Implementation:

[0129] Test No. 1=Point of CO.sub.2 introduction on the discharge side of the pump for draining the pulper 15;

[0130] Test No. 2=Point of CO.sub.2 introduction on the discharge side of the pump for the tank 25 in the loop circuit;

[0131] Test No. 3=Point of CO.sub.2 introduction on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com