High tensile hot-rolled steel sheet having excellent strain aging hardening properties and method for producing the same

a high-tensile, hot-rolled steel technology, applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems that conventional steel sheets cannot be applied to components in which high reliability was required, and achieve the effect of increasing bh and .delta.ts, and reducing ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0146] The steel having the composition shown in Table 4 was cast into a slab in the same manner as Example 1, and the slab was hot-rolled under the conditions shown in Table 5. Thereby, hot-rolled steel sheets (with a thickness of 1.6 mm) in which the average cooling rates were greatly varied were obtained. In such a case, when finish-rolling was performed, consecutive sheet bars with a thickness of 25 mm were joined to each other by fusion-pressure welding at the initial stand, and tandem rolling was performed continuously. Between rough-rolling and finish-rolling, the temperature of the sheet bar was adjusted using a sheet bar edge heater and a sheet bar heater of induction heating type. The resultant hot-rolled steel sheets were investigated in the same manner as Example 1.

[0147] The results thereof are shown in Table 6. In all the steel sheets, it is clear that the strain aging hardenability was stable at a high level. In Example 2, due to the continuous rolling and the tempera...

example 3

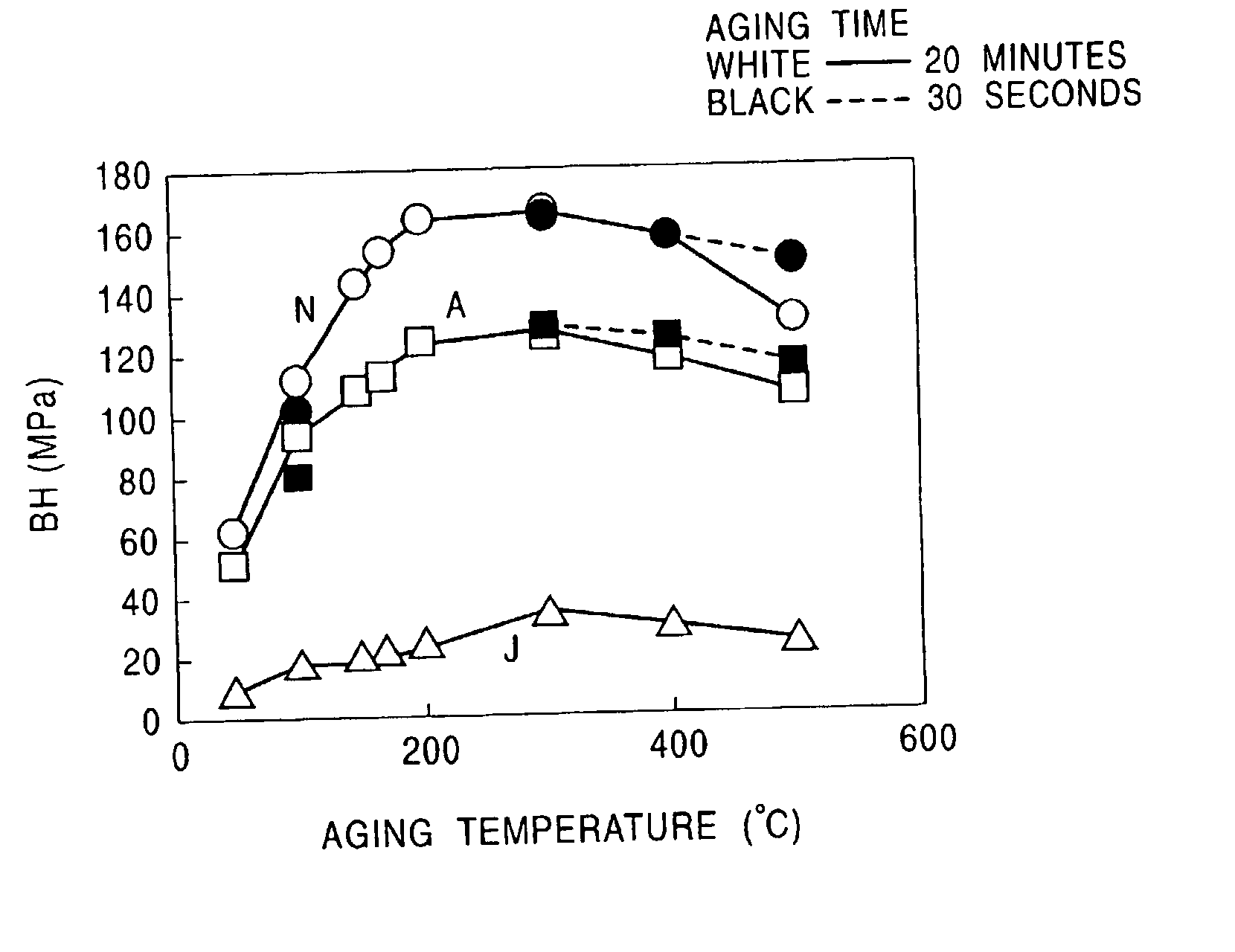

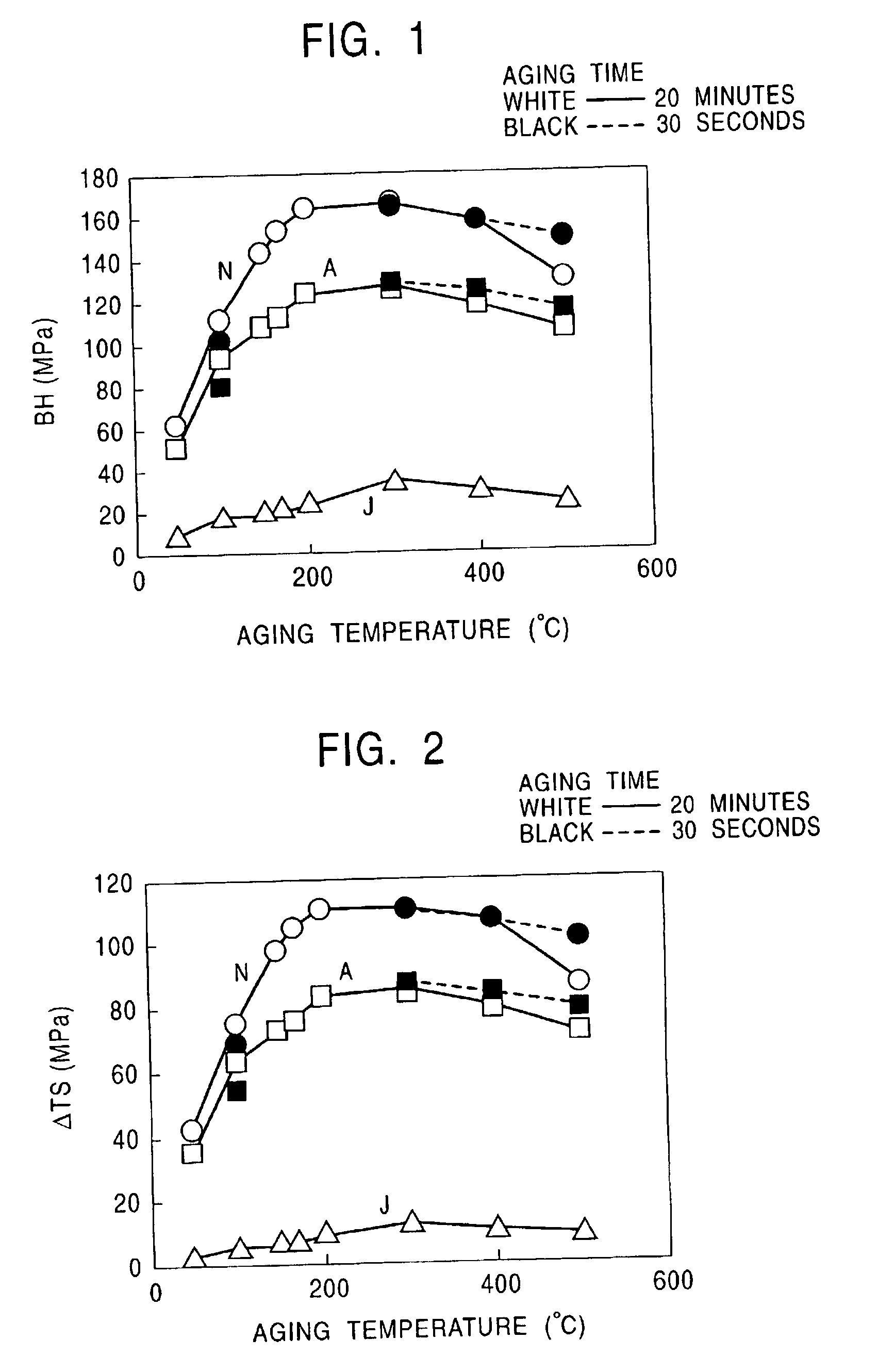

[0148] With respect to the steel sheet Nos. A, N, and J shown in Table 3, the BH (increase in deformation stress) and the .DELTA.TS (increase in tensile strength) were investigated with varied aging treatment conditions. The results thereof are shown in FIGS. 1 and 2. In the examples of the present invention (A and N), significantly greater hardening was observed compared to the comparative example (J) in the low-temperature, short-time aging treatment. Thereby, it is obvious that the steel sheet of the present invention has superior strain aging hardenability. It is also clear that the examples A and N of the present invention exhibit superior strain aging hardenability under the strain aging treatment conditions in the wide ranges of 100 to 300.degree. C..times.30 seconds to 20 minutes.

example 4

[0149] Each of the steels having the compositions shown in Tables 7 and 8 was melted in a converter, and a slab was formed by continuous casting. The slab was hot-rolled under the conditions shown in Tables 9 and 10 to produce a hot-rolled steel sheet. With respect to the resultant hot-rolled steel sheet, the dissolved N, the microstructure, the tensile characteristics, strain aging hardenability, and improvements in fatigue resistance and impact resistance due to strain aging treatment were investigated.

[0150] The amount of dissolved N was measured by the method described above.

[0151] In order to observe the microstructure, with respect to the C cross section (the cross section perpendicular to the rolling direction) in the center in the thickness direction, the enlarged image of the structure appearing due to corrosion was analyzed.

[0152] The tensile tests for checking the tensile characteristics and the strain aging hardenability were performed according to JIS Z 2241 using JIS N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com