Method of preparing an anisotropic polymer film on a substrate with a structured surface

a polymer film and structured surface technology, applied in the field of preparing anisotropic polymer films on structured surfaces, can solve the problems of increasing costs, increasing methods of the prior art, and difficulty in forming patterned films comprising regions of different orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0086]

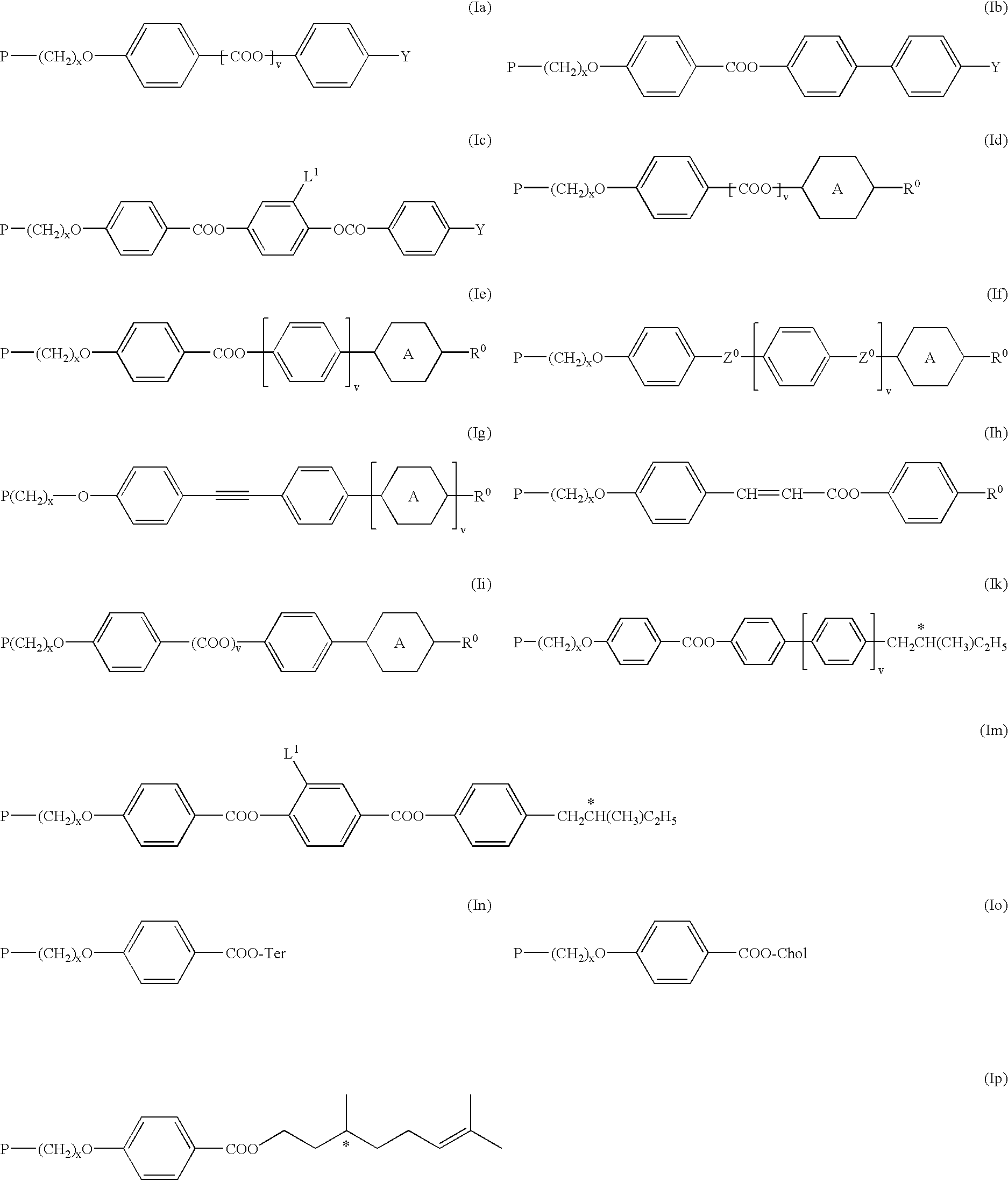

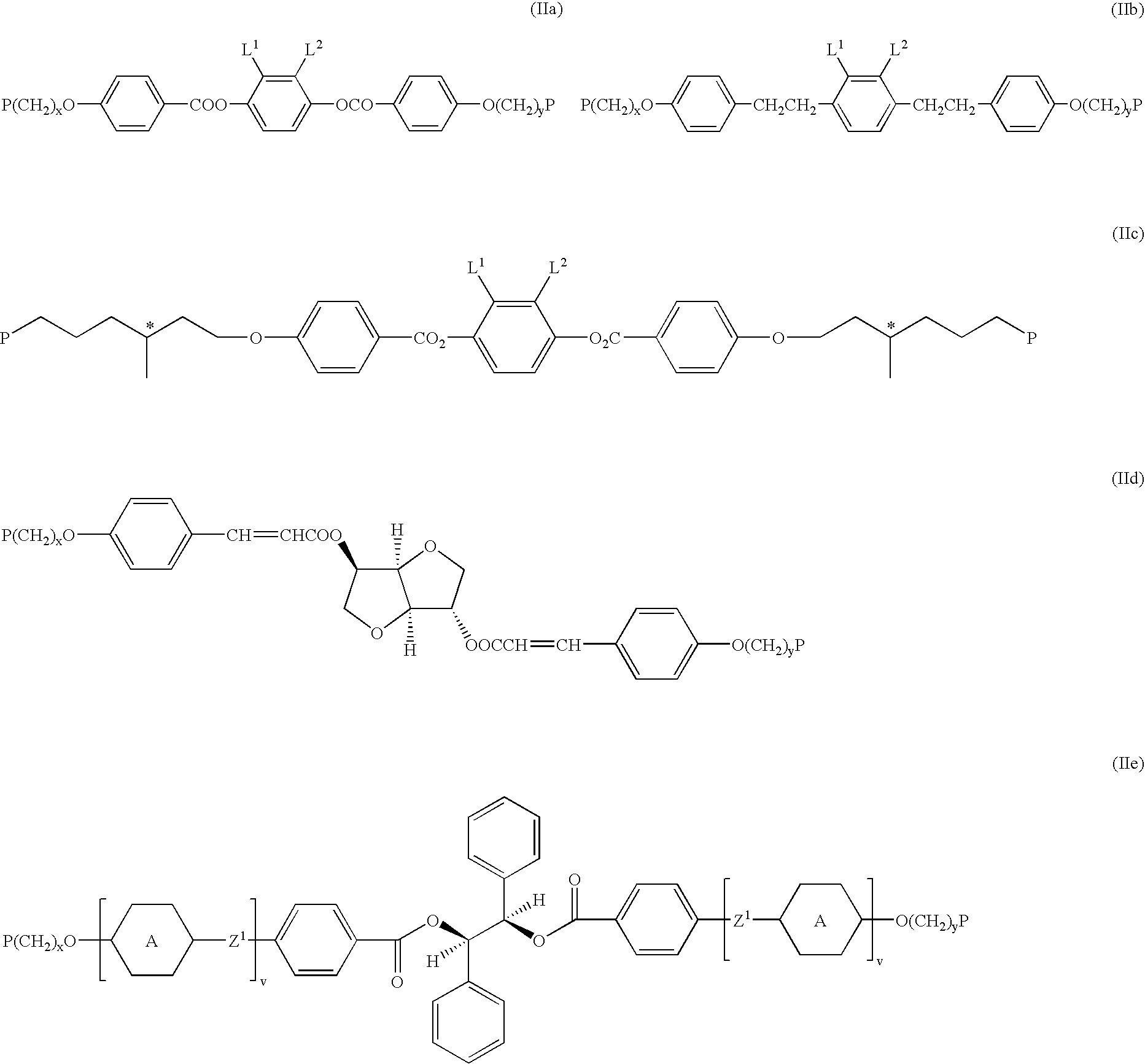

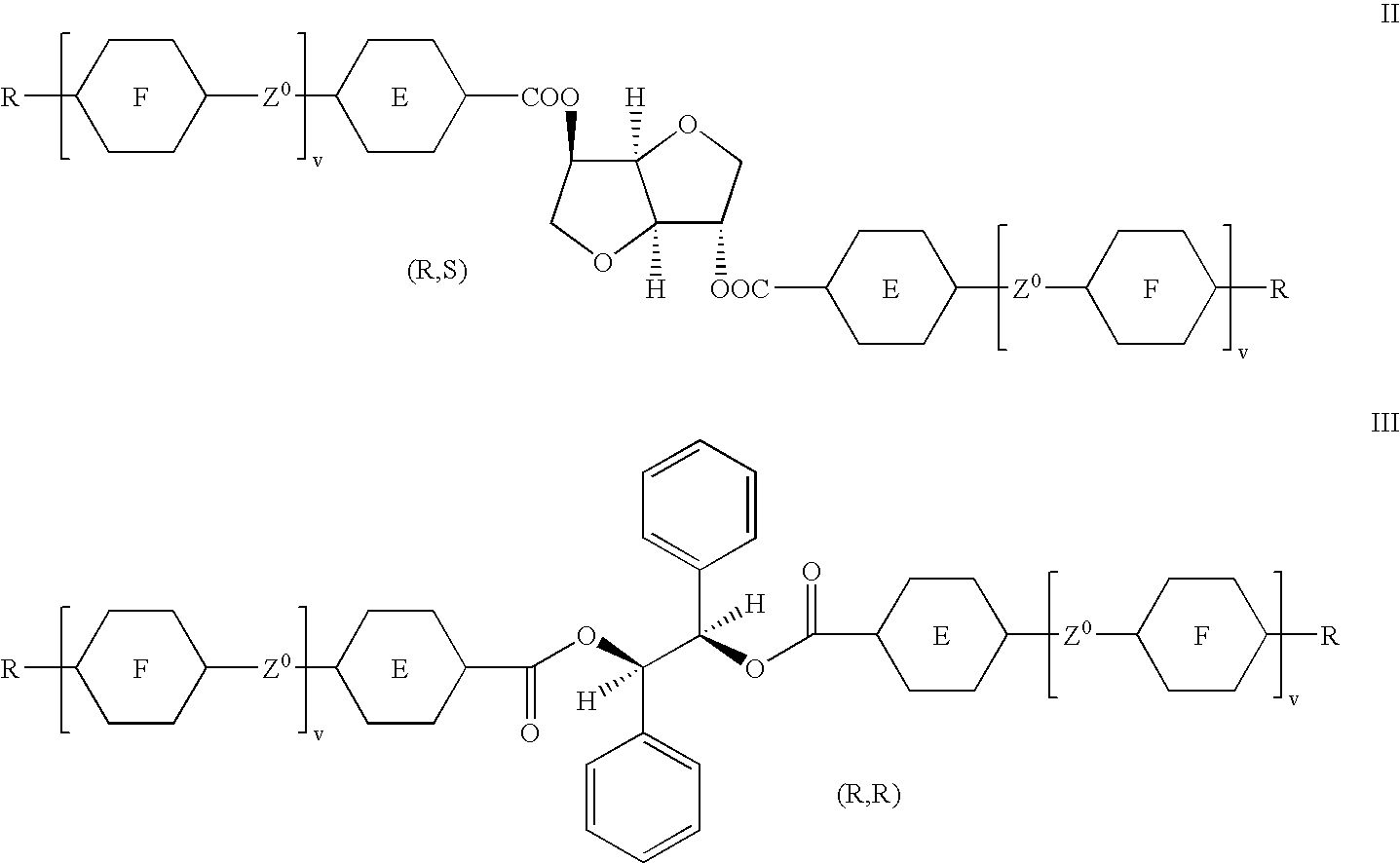

1 The following polymerisable mixture is formulated Toluene 70.0% compound A 6.9% compound B 3.6% compound C 9.1% compound D 8.5% Fluorad FC-171 .RTM. 0.1% Irgacure 907 .RTM. 1.8% (A) 4 (B) 5 (C) 6 (D) 7

[0087] Compound (A) and its preparation are described in GB 2,280,445. Compounds (B), (C) and (D) can be prepared according to or in analogy to the methods described in D. J. Broer et al., Makromol. Chem. 190, 3201-3215 (1989). Irgacure 907 is a commercially available photoinitiator (Ciba Geigy). Fluorad FC 171 is a commercially available surfactant (3M).

[0088] This solution is coated on to an embossed film, where the embossing is in a single direction, using for example a wire wound bar to give a 6 micron wet film. This coating is then dried at 60.degree. C. for one minute and cured by exposing to the light from a medium pressure mercury lamp for one minute. When viewed through a linear polariser against a reflective background a dark blue colour is seen.

example 2

[0089] The solution of Example 1 is coated on to an embossed film where the embossing is in domains having differing directions using a wire wound bar to give a 6 micron wet film. This coating is then dried at 60.degree. C. for one minute and cured by exposure to the light from a medium pressure mercury lamp for one minute. When viewed through a rotating linear polariser against a reflective background a dark blue colour is seen only in regions having the appropriate alignment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com