Processing apparatus and cleaning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

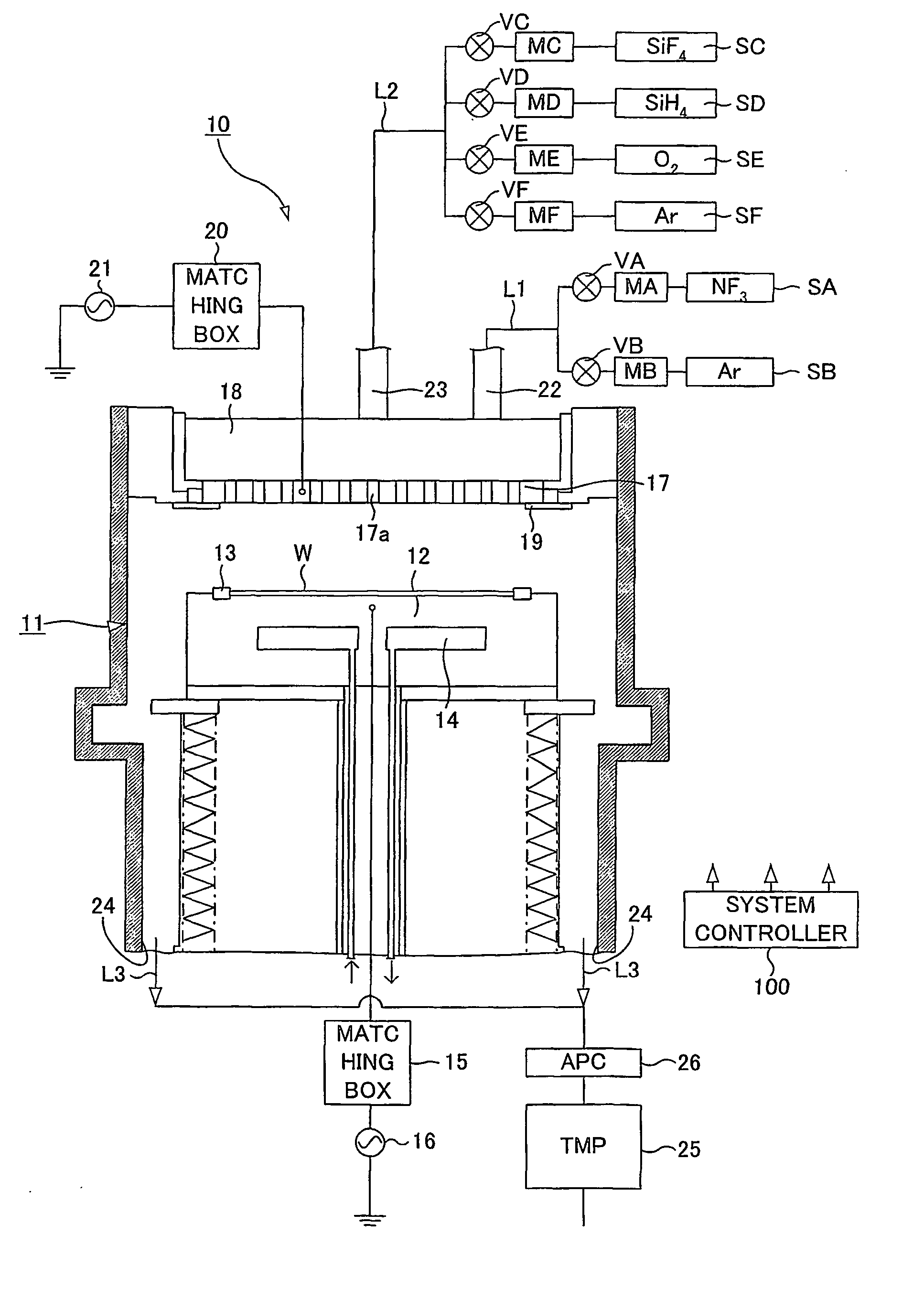

first embodiment

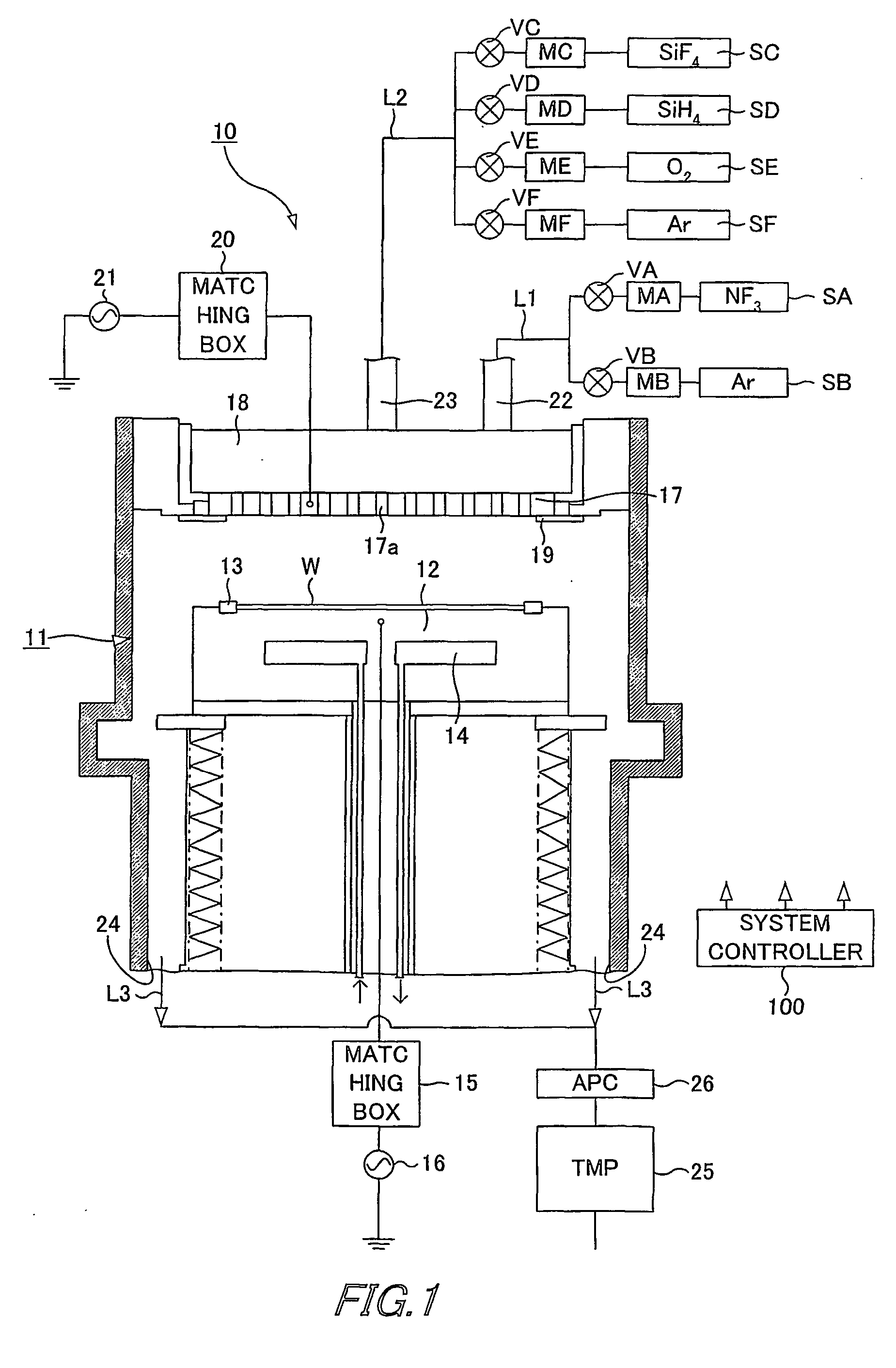

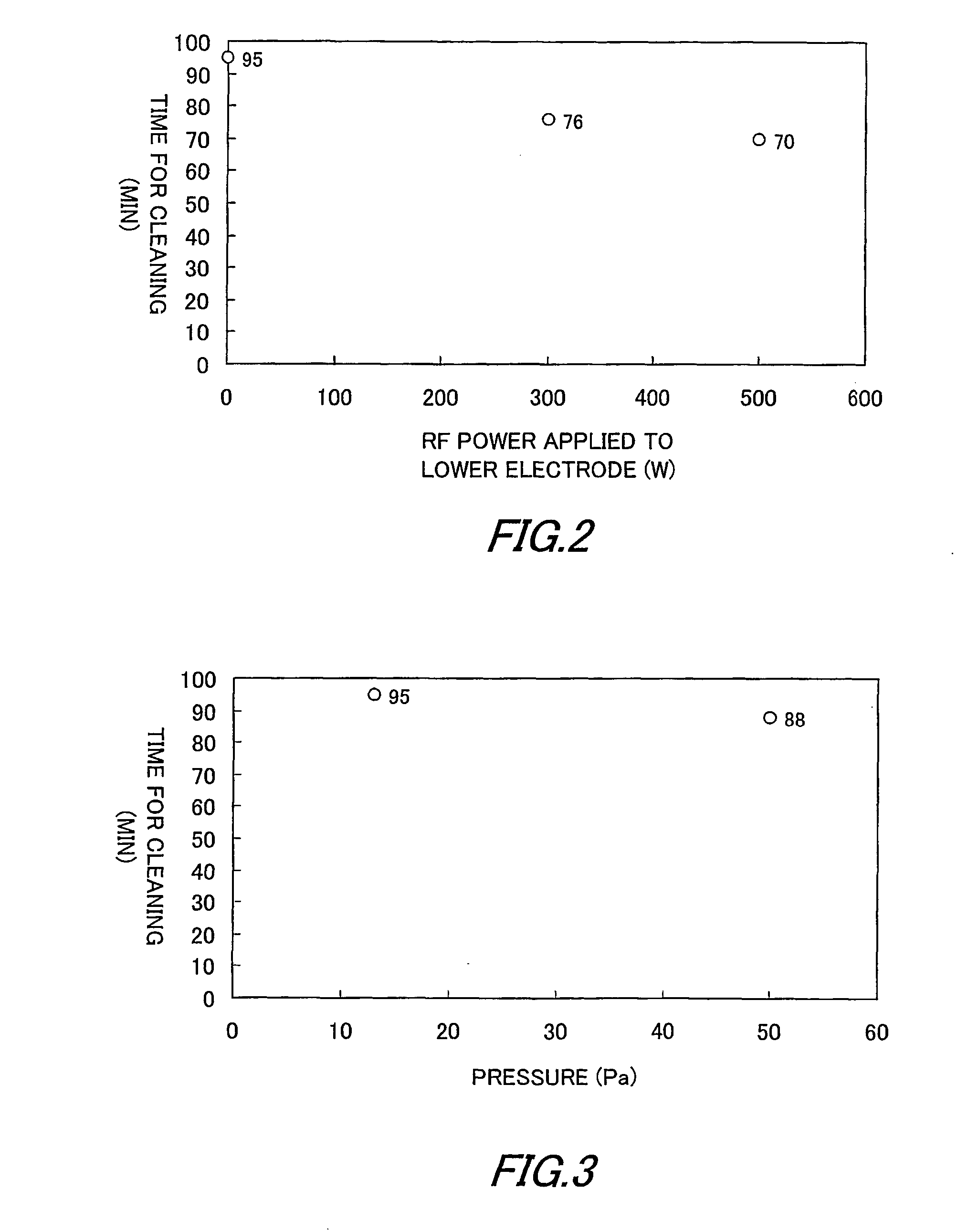

[0055] FIGS. 2 and 3 show cleaning results achieved after the film formation which is done using the plasma processing apparatus 10 according to the present invention.

[0056] In this Example 1, during a film formation, a SiOF film is formed to have a thickness of 5 .mu.m on the wafer W, within the distance 50 mm between the electrodes. In addition, during a cleaning process, the system controller 100 supplies the chamber 11 with NF.sub.3 / Ar=500 / 500 (sccm / sccm) at a pressure of 13 Pa, and applies an RF power of 1500W to the upper electrode (the electrode plate 17).

[0057] FIG. 2 shows the relationship between the cleaning time and the applied RF power, in the case where the cleaning is performed with applying the RF power to the upper and lower electrodes using the processing apparatus of the first embodiment. As seen from FIG. 2, it is clear that the processing apparatus which applies the RF power to the upper and lower electrodes can achieve the cleaning at a shorter period of time t...

second embodiment

[0060] A processing apparatus according to the second embodiment includes a chamber. Inside the chamber, a SiOF film is formed on a wafer W using a plasma CVD method, with a process gas containing SiH.sub.4, SiF.sub.4, and O.sub.2. The SiOF film deposited inside the chamber after the film formation process is removed using a cleaning gas including NF.sub.3. The cleaning gas is activated outside the chamber so as to be used.

[0061] FIG. 4 shows the structure of the processing apparatus 10 according to the second embodiment of the present invention. FIG. 5 is a cross sectional view of the processing apparatus 10. In FIGS. 4 and 5, the same components are identified by the same reference numerals.

[0062] As shown in FIG. 4, the processing apparatus 10 of the second embodiment includes a cleaning-gas line L4 provided with an activator 27.

[0063] The activator 27 is connected to the cleaning gas source SA and the carrier gas source SB respectively through the valves VA and VB and also throu...

example 2

[0071] FIG. 6 shows the relationship between the time for cleaning and the pressure inside the chamber 11, and shows some results of the cleaning done after the film formation, using the processing apparatus according to the second embodiment of the present invention. In Example 2, during the process for forming the film, a SiOF film is formed to have a thickness of 5 .mu.m on the wafer W, with the distance of 50 mm between the electrodes.

[0072] FIG. 6 shows the results of the cleaning with a variety of pressure levels. As seen from FIG. 6, as compared to the case where the pressure inside the chamber 11 is in a high vacuum state of approximately 0 Pa, a high cleaning rate can be obtained if the pressure is within a range between 100 Pa and 400 Pa. Note also that, in the case where the pressure inside the chamber 11 is approximately 200 Pa, the most highest cleaning rate can be obtained. According to the second embodiment wherein the cleaning is performed at a pressure in a range be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com