Annular combustion chamber for a gas turbine

a gas turbine and combustion chamber technology, applied in the direction of machines/engines, efficient propulsion technologies, lighting and heating apparatus, etc., can solve the problems of unnecessari cooling of hot working gas, inconvenient operation, and inability to be leak-proof, etc., to achieve simple and low leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The Figures are not to scale and only serve for explanatory purposes. The same elements have the same reference characters in the Figures.

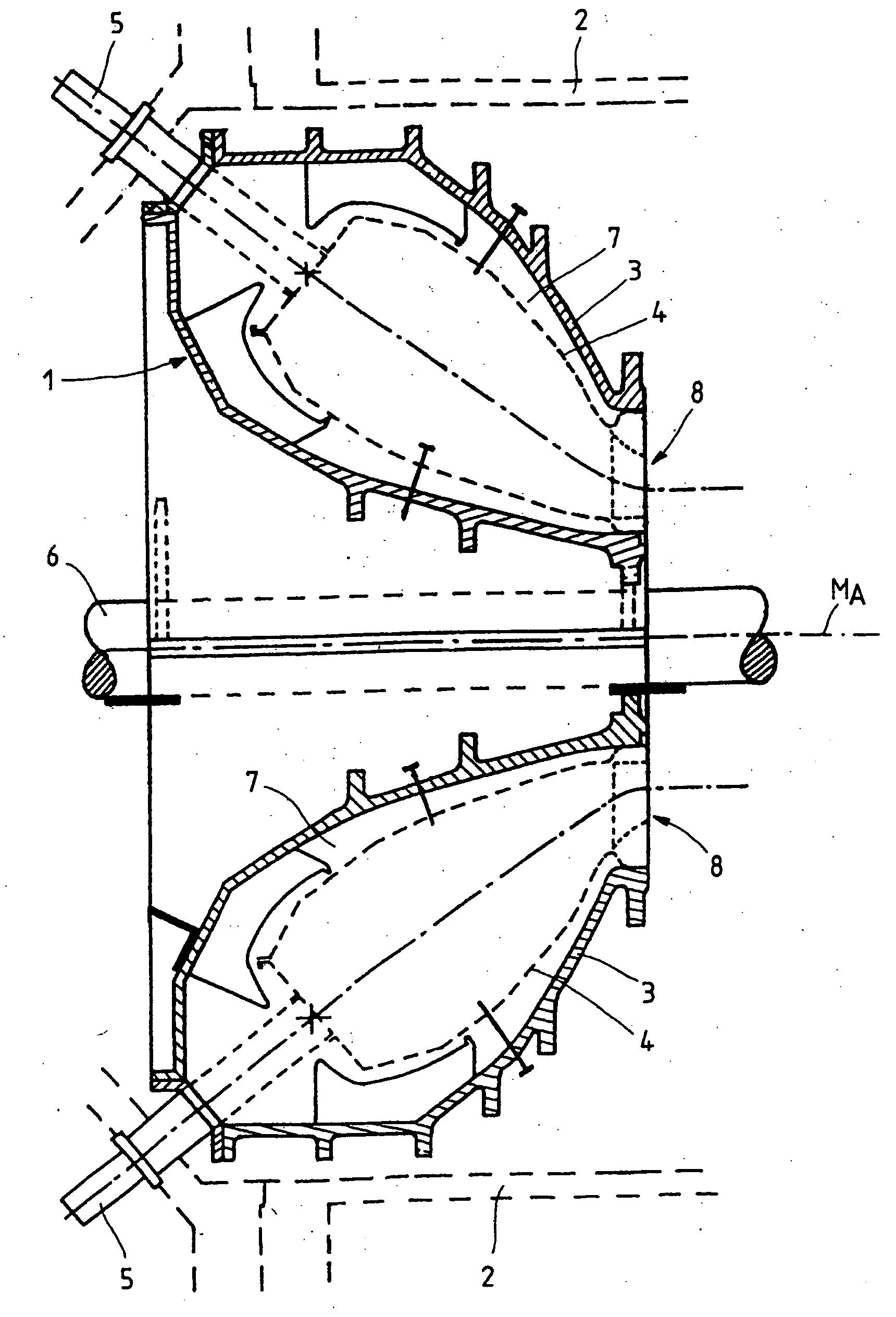

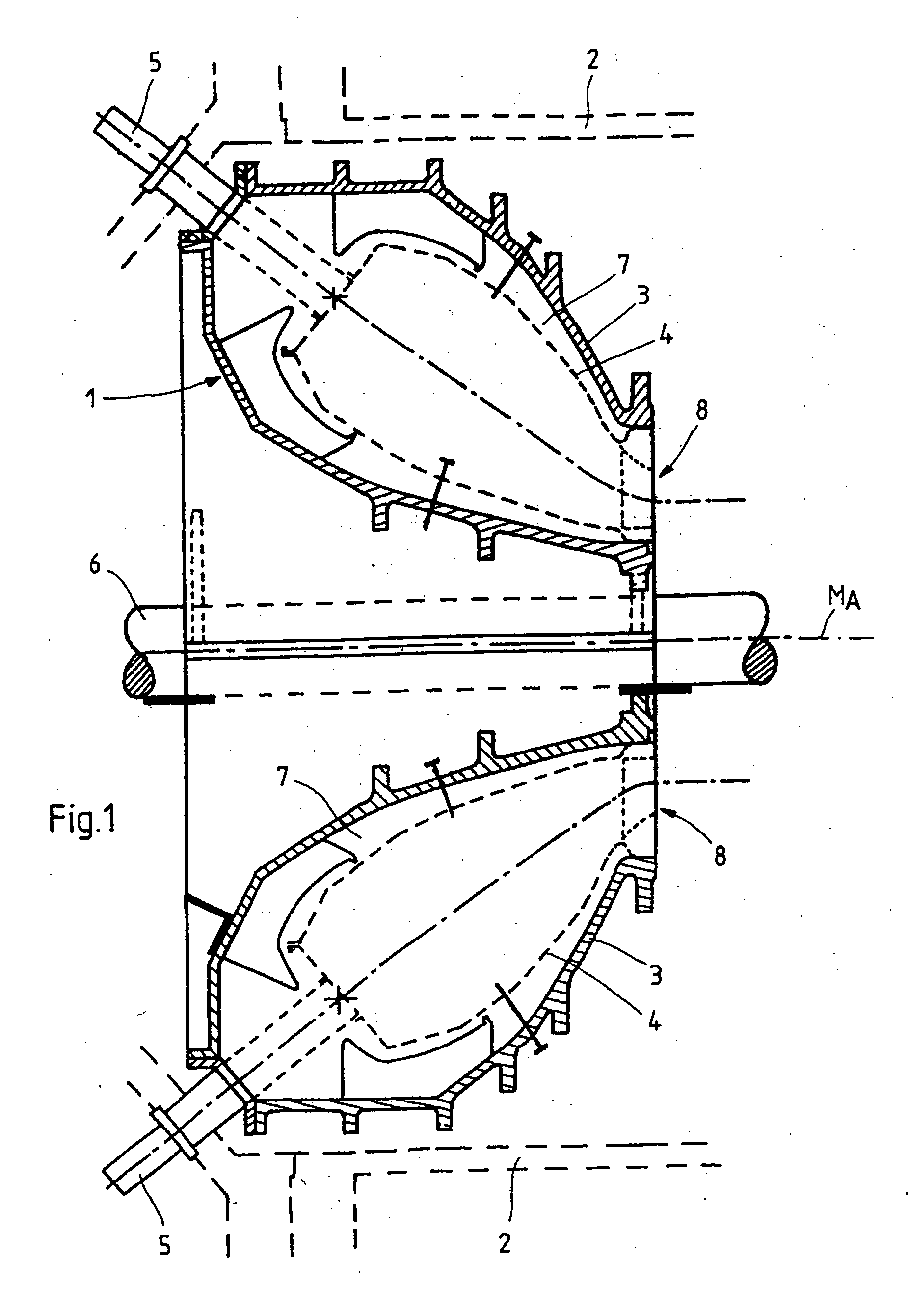

[0047] FIG. 1 shows a schematic representation of a longitudinal cross-section through an inventive annular combustion chamber 1 and its position in relation to further components of the turbine.

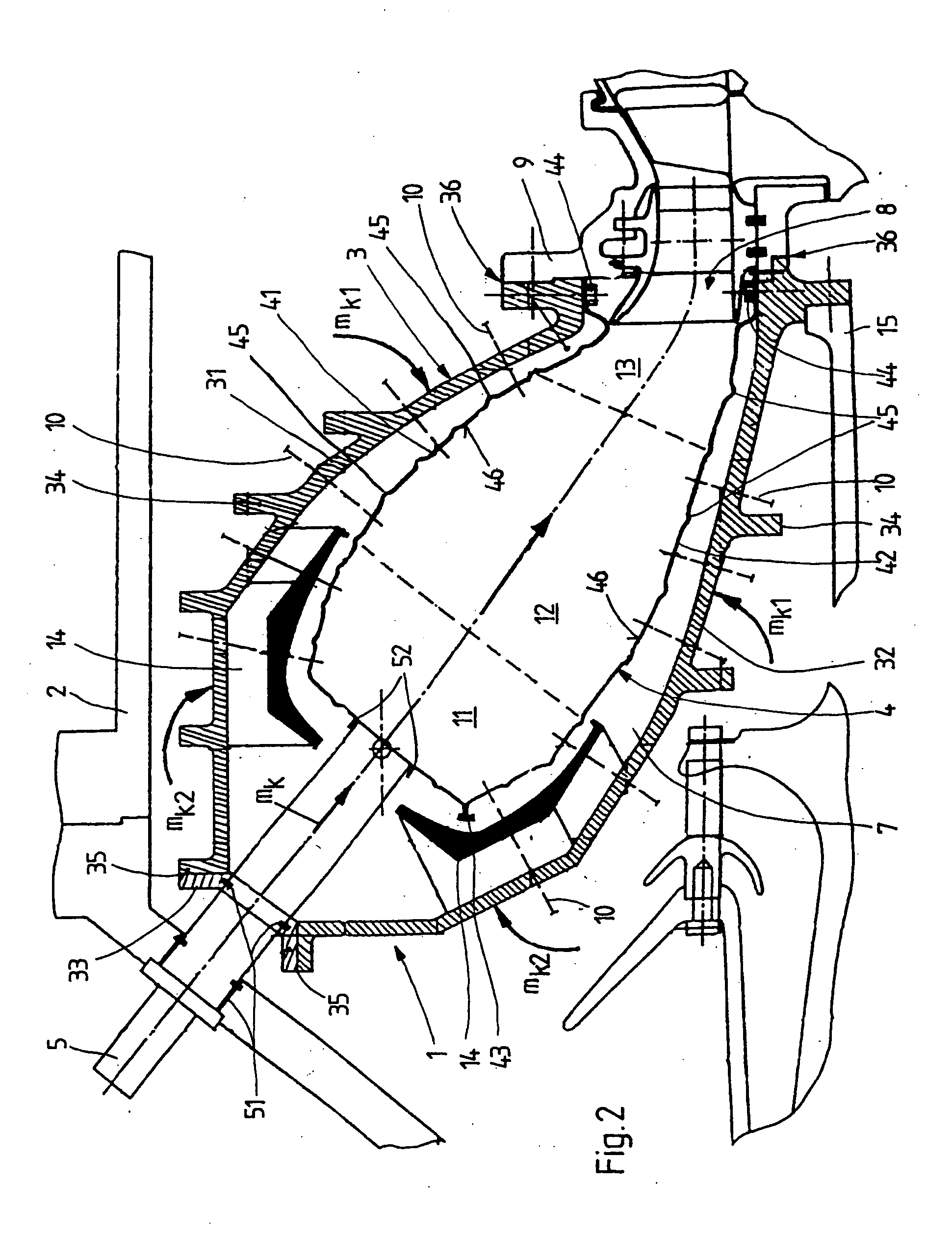

[0048] The annular combustion chamber housing 1,3 is supported on the spatially bound shaft guard 53 and is linked to the pressure-resistant outer housing 2; the annular combustion chamber housing is in three parts: it comprises the inner hub housing 1, the outer external shell housing 3 and the connecting burner housing 33. The liner is located in the "torus" formed by the elements 1,3,33 and comprises the outer liner 41 and the inner liner 4. All the housing components are partitioned axially across a sub-joint flange. An annular chamber 7 extending outwards, in which the cooling air is collected and fed to the burners 5, is left between the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com